Aporate amphion switching biology isolate medium as well as its preparing method and usage

A zwitterion and biological separation technology, applied in the direction of zwitterion exchange, inorganic cation exchanger, inorganic anion exchanger, etc., can solve the problem of difficult separation, achieve good separation reproducibility, fast speed, improve separation and analysis effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

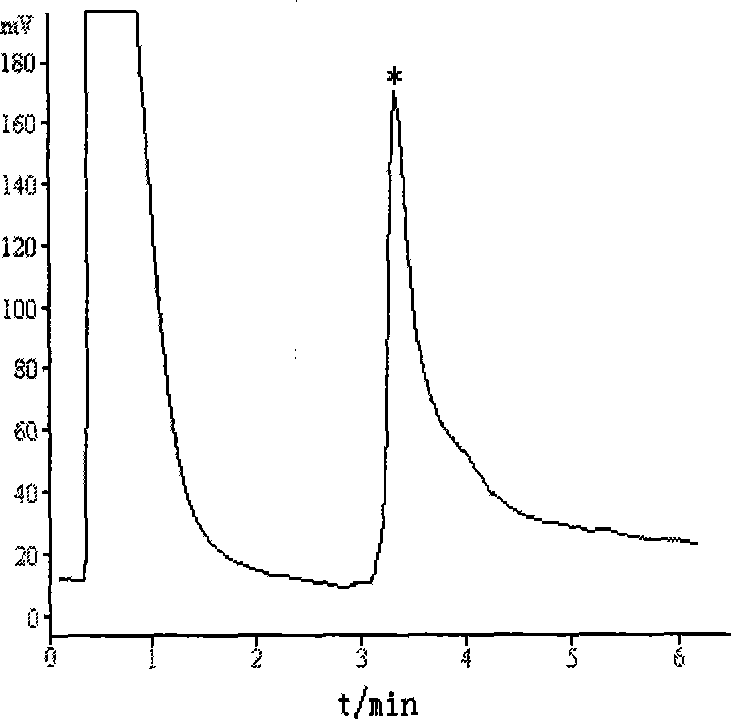

Image

Examples

Embodiment 1

[0027] Embodiment 1: A kind of non-porous amphoteric ion exchange biological separation medium: its structural formula is:

[0028]

[0029] where the structure of P is:

[0030]

[0031] The preparation method of the non-porous amphoteric ion-exchange bio-separation medium: add 40 mL of 1.0 mol / L dilute HCl to 4.0 g of non-porous monodisperse P (GMA / EDMA) resin, ultrasonically disperse for 10 min, and then react at a constant temperature of 30-40 ° C for 2 h. Suction filtration, repeated washing with distilled water until neutral, add 30mL aqueous solution of dimethylamine to the product, react at constant temperature 60°C for 20h, wash the product repeatedly with a large amount of water and acetone, and vacuum dry to obtain ammoniated microspheres. Add 3g of 1,3-propane sultone to the microspheres in 120mL of acetonitrile, ultrasonically disperse and stir at 80°C for 20 hours at reflux, wash the product with a large amount of acetone and ethanol, and dry it in vacuum. ...

Embodiment 2

[0034] Embodiment 2: A kind of non-porous amphoteric ion exchange biological separation medium: its structural formula is:

[0035]

[0036] where the structure of P is:

[0037]

[0038] The preparation method of the non-porous amphoteric ion-exchange bio-separation medium: add 50 mL of 1.0 mol / L dilute HCl to 5.0 g of non-porous monodisperse P (GMA / EDMA) resin, ultrasonically disperse for 12 min, and react at a constant temperature of 30-40 °C for 2.5 h , filtered with suction, washed repeatedly with distilled water until neutral, then added 40mL of dimethylamine aqueous solution to the product, reacted at a constant temperature of 65°C for 22h, washed the product repeatedly with a large amount of water and acetone, and dried in vacuum to obtain ammoniated microspheres. Add 4g of 1,3-propane sultone into 135mL of acetonitrile, ultrasonically disperse and stir at 85°C for 22 hours at reflux, wash the product with a large amount of acetone and ethanol, and dry it in vacu...

Embodiment 3

[0041] Embodiment three: a kind of non-porous amphoteric ion exchange biological separation medium: its structural formula is:

[0042]

[0043] where the structure of P is:

[0044]

[0045] The preparation method of the non-porous amphoteric ion-exchange bio-separation medium: add 60 mL of 1.0 mol / L dilute HCl to 6.0 g of non-porous monodisperse P (GMA / EDMA) resin, ultrasonically disperse for 15 min, react at a constant temperature of 40 °C for 3 h, and filter with suction , washed repeatedly with distilled water until neutral, then add 50mL of dimethylamine aqueous solution to the product, react at a constant temperature of 70°C for 24 hours, wash the product repeatedly with a large amount of water and acetone, and dry it in vacuum to obtain ammoniated microspheres. The ammoniated microspheres In 150mL of acetonitrile, add 5g of 1,3-propane sultone, reflux and stir at 90°C for 24 hours after ultrasonic dispersion, wash the product with a large amount of acetone and et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com