Method for preparing carbon nanometer tube/hydroxyapatite complex powder through in-situ vapour deposition reaction

A technology of hydroxyapatite and carbon nanotubes, applied in medical science, prosthesis, surgery, etc., to achieve the effect of high purity, good quality and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

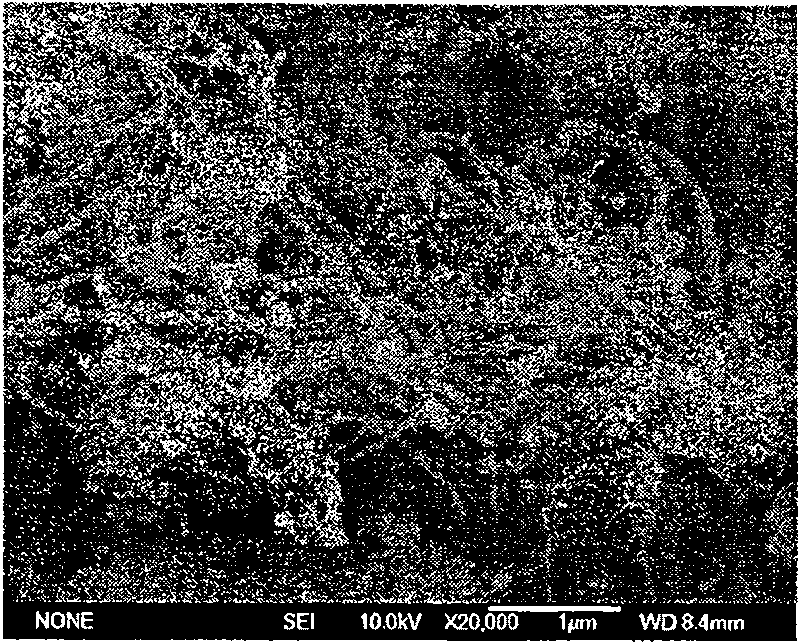

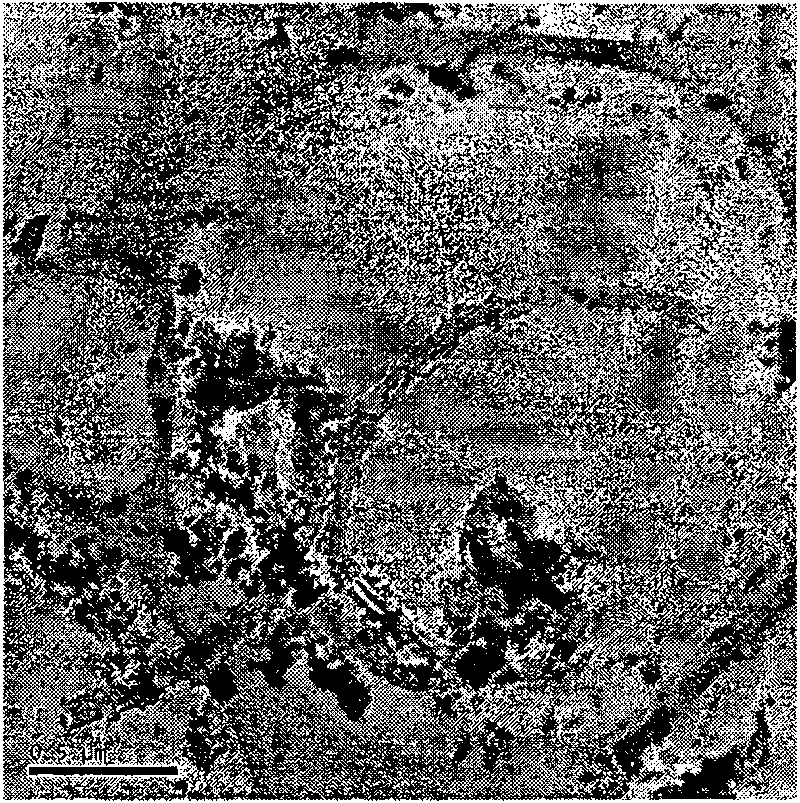

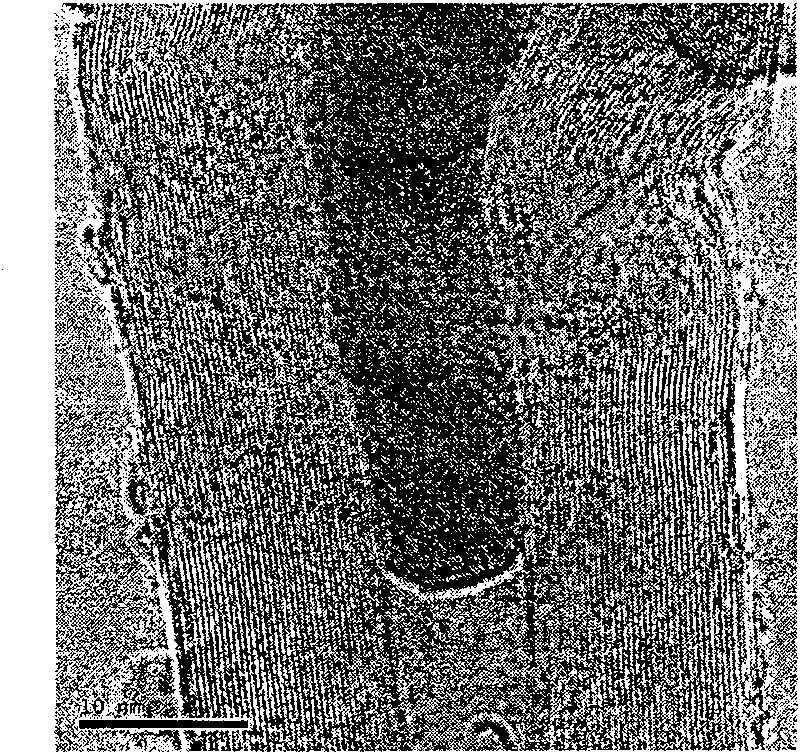

Image

Examples

Embodiment 1

[0017] Add 0.056g ferric nitrate nonahydrate and 1.287g HA powder into deionized water to prepare a ferric nitrate nonahydrate solution containing HA at a concentration of 0.05mol / L, and add 0.05mol / L sodium hydroxide solution dropwise to the solution to make the solution pH = 7.0 and precipitated to produce Fe / Ca 10 (PO 4 ) 6 (OH) 2 Fe(OH) with a mass ratio of 0.01:1 3 / Ca 10 (PO 4 ) 6 (OH) 2 Binary colloid; the binary colloid is dehydrated at 250°C under nitrogen atmosphere, and calcined at 450°C to obtain Fe / Ca 10 (PO 4 ) 6 (OH) 2 Catalyst precursor Fe 2 o 3 / Ca 10 (PO 4 ) 6 (OH) 2 ; The obtained Fe / Ca 10 (PO 4 ) 6 (OH) 2 Catalyst precursor Fe 2 o 3 / Ca 10 (PO 4 ) 6 (OH) 2 The powder is spread in a quartz boat, and the quartz boat is placed in the constant temperature zone in the middle of the reaction tube; the air in the tube is vented with nitrogen gas, and then the temperature is raised to 550°C; hydrogen gas is passed into the reactor at 200ml...

Embodiment 2

[0019] The experimental conditions and process of this example are the same as those in Example 1, except that the catalytic cracking reaction time is 2 hours, and the CNTs / HA composite powder is obtained. The yield of CNTs is 0.05%, the average diameter is 13 nm, and the average length is 2.7 μm.

Embodiment 3

[0021] The experimental conditions and process of this example are the same as in Example 1, except that the catalytic cracking reaction temperature is 650°C, and the CNTs / HA composite powder is obtained. The yield of CNTs is 0.06%, the average diameter is 14nm, and the average length is 2.4μm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com