Polysiloxane resin with lateral group containing alkoxyl, producing method and use of the same

A technology of polysiloxane resin and side groups containing alkanes, which is applied in chemical instruments and methods, other chemical processes, coatings, etc., can solve the problems of low mechanical strength of cross-linked products, and achieve excellent high temperature resistance and good durability. The effect of chemical corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of polysiloxane resin (PMOS) containing methoxy group in side group:

[0039] Raw materials: methyl hydrogen-containing silicone oil with a hydrogen content of 1.6mol / 100g; methanol as the alcohol; tetrahydrofuran as the solvent; tetramethylammonium hydroxide as the catalyst.

[0040] Conditions: Add 100g of methyl hydrogen-containing silicone oil, 52g of methanol, 100g of tetrahydrofuran, and 1.0g of tetramethylammonium hydroxide into a three-necked flask, and react for 3 hours at a reaction temperature of 0°C.

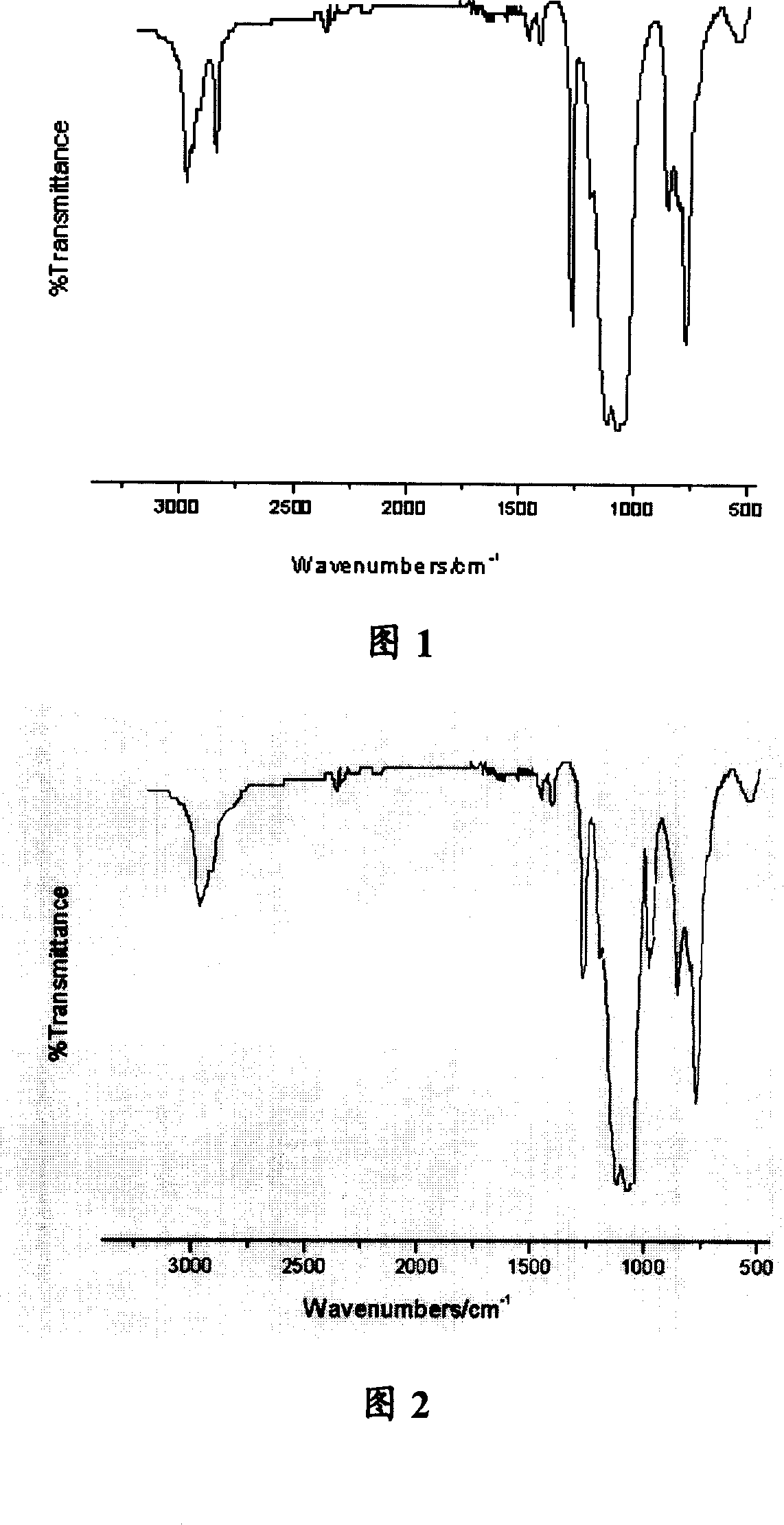

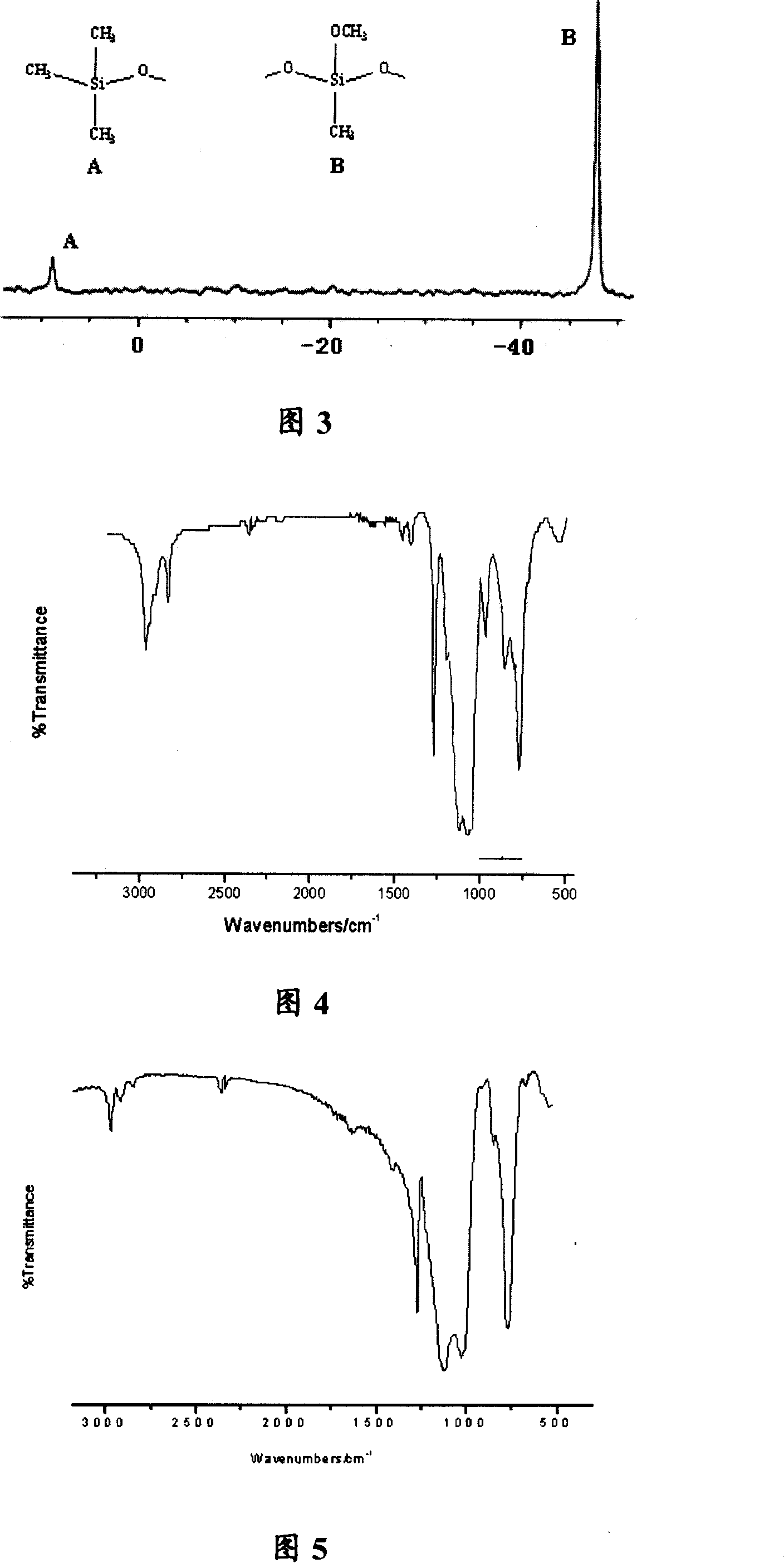

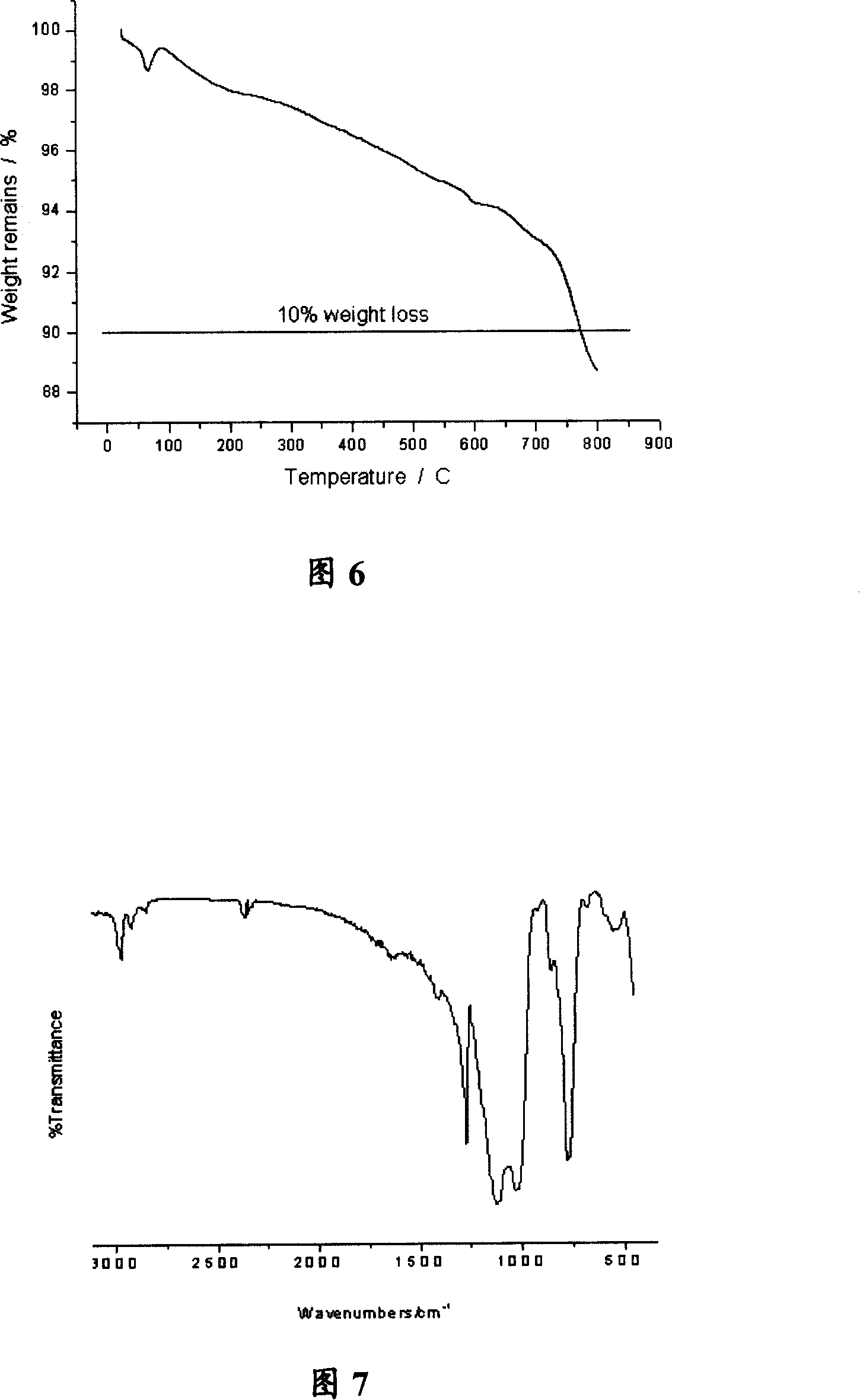

[0041] The synthetic product is liquid at room temperature, and it is characterized by infrared. Compared with the infrared spectrum of the raw material methyl hydrogen-containing silicone oil, the 2173cm -1 The characteristic peak at disappears, indicating that the Si-H group is reacted; 2841cm -1 A new characteristic peak appears at , indicating that there is Si-OCH 3 Group generation. Perform on PMOS 29 Si NMR characterization, compared with t...

Embodiment 2

[0046] Preparation of polysiloxane resin (PEOS) containing ethoxy groups in side groups:

[0047] Raw materials: methyl hydrogen-containing silicone oil with a hydrogen content of 0.09mol / 100g; ethanol is selected as alcohol; toluene is selected as solvent; basic ion exchange resin is selected as catalyst.

[0048] Conditions: Add 100g of hydrogen-containing silicone oil, 5g of ethanol, 200g of toluene, and 5.0g of basic ion exchange resin into a three-necked flask, and react for 17 hours at a reaction temperature of 60°C.

[0049] The synthesized product is liquid at room temperature, and it is characterized by infrared. Compared with the infrared spectrum of the raw material methyl hydrogen-containing silicone oil, the 2173cm -1 The characteristic peak at disappears, indicating that the Si-H group is reacted; 920cm -1 A new characteristic peak appears at , indicating that there is Si-OCH 2 CH 3 Group generation. The above infrared characterization shows that under the pr...

Embodiment 3

[0053] Preparation of polysiloxane resin (PMOS) containing methoxy group in side group:

[0054] Raw materials: methyl hydrogen-containing silicone oil, hydrogen content is 1.66mol / 100g; methanol is selected as alcohol; acetone is selected as solvent; copper powder is selected as catalyst.

[0055] Conditions: Add 100g of methyl hydrogen-containing silicone oil, 60g of methanol, 100g of acetone, and 4.0g of copper powder into a three-necked flask, and react for 20 hours at a reaction temperature of 50°C.

[0056] The synthetic product is liquid at room temperature, and it is characterized by infrared. Compared with the infrared spectrum of the raw material methyl hydrogen-containing silicone oil, the 2173cm -1 The characteristic peak at disappears, indicating that the Si-H group is reacted; 2841cm -1 A new characteristic peak appears at , indicating that there is Si-OCH 3 Group generation. Perform on PMOS 29 Si NMR characterization, compared with the NMR spectrum of the ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com