Hybrid power drive device based on mechanical automatic speed-changer

An automatic transmission and hybrid technology, which is applied to transmissions, transmission parts, gear transmissions, etc., can solve the problems of few working modes, uncompact layout, and difficult to meet, and achieve the effect of improving economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

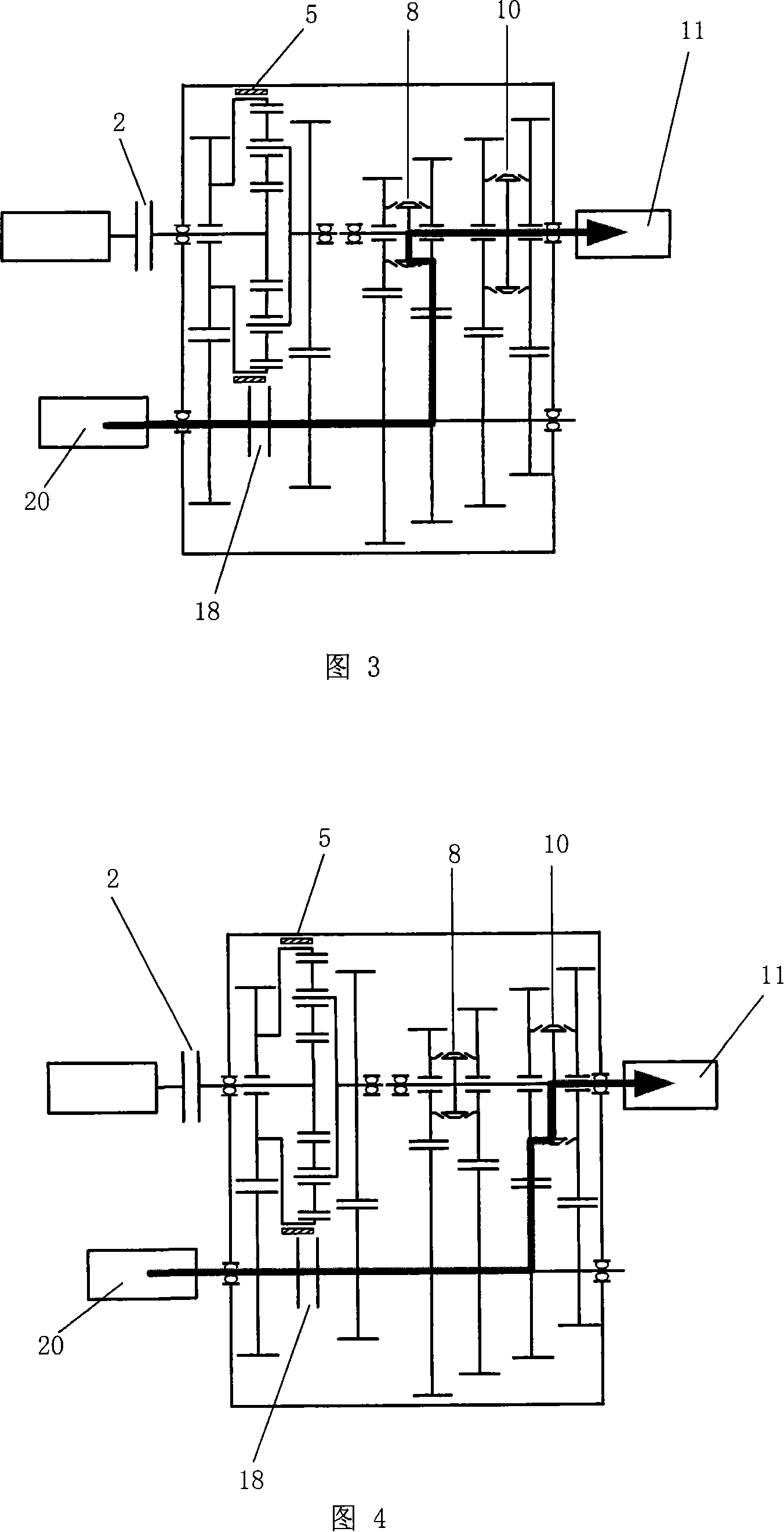

[0063] Please refer to the accompanying drawings for a further description of the present invention.

[0064] As shown in Fig. 1, the present invention provides a kind of hybrid driving device based on mechanical automatic transmission, including fuel power, electric power and a power output end, and this device is provided with a brake 5, two clutches, a four-speed mechanical Automatic transmission, a planetary gear mechanism, in which the planetary gear is composed of sun gear 22, ring gear 4, planetary carrier 6 and planetary gear 21, and the four-speed mechanical automatic transmission is composed of constant mesh gear pairs O12, P13, Q14, R15, synchronizer M8 , N10, shafts G9, H16, output end 11, and a meshing gear pair composed of gears C3, D19 and gears E7, F17. The motor 20 is connected with the gear D19, and the shaft H16 is connected through the clutch B18. The internal combustion engine 1 is connected through the clutch A2 is connected with the sun gear 22, by contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com