Preparation method for nucleoside compounds

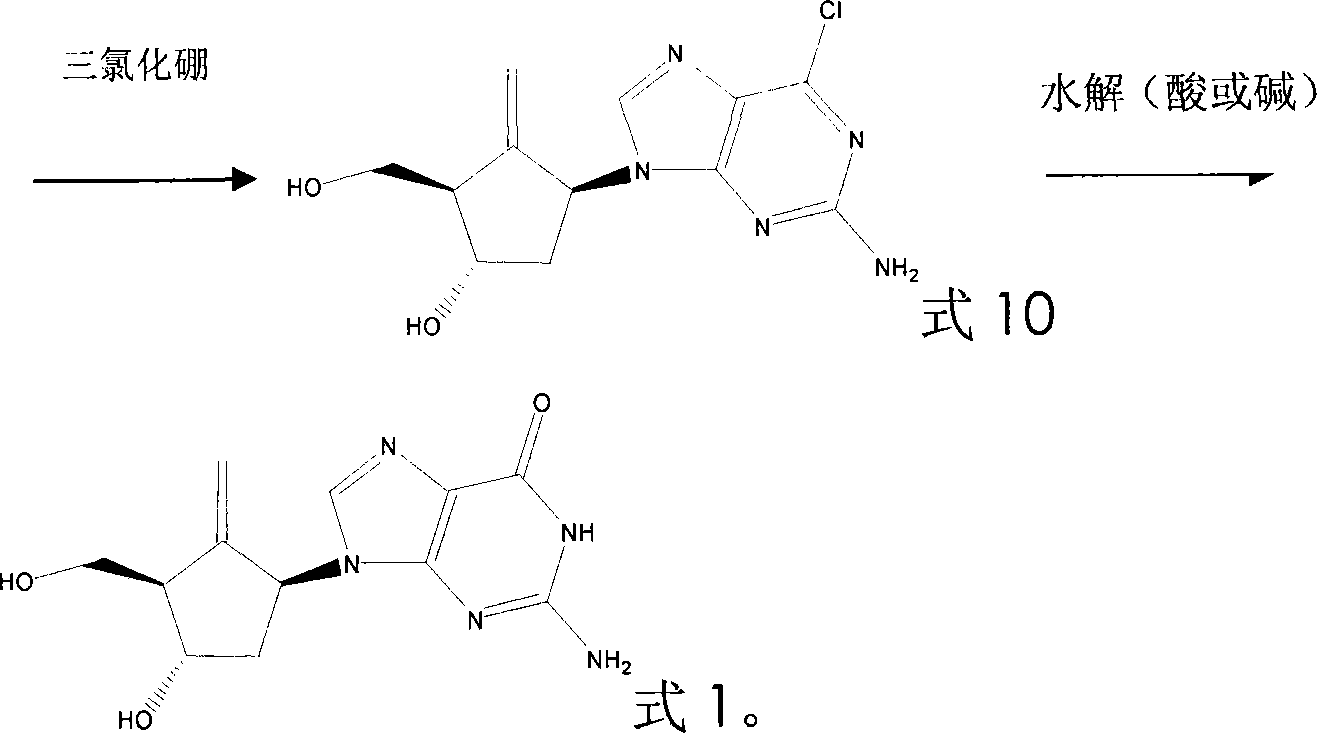

A technology for nucleoside compounds and compounds, which is applied in the production of organic chemistry and bulk chemicals to achieve the effect of easy availability of raw materials and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] 1. [1s-(1α, 2β, 3α, 5β)]-5-succinimide-3-(benzyloxy)-2-[(benzyloxy)methyl]cyclopentanol (formula 3 compound) preparation:

[0021] In a 2L three-neck flask, add 600ml of anhydrous DMF and 65g (0.66mol) of succinimide, add 2.3g of LiH (0.33mol) while stirring, continue stirring for 30min, and the solution becomes clear. Add 102.3g (0.33mol) of the compound of formula 3 dropwise, heat up to 120°C, and react for 3h. TLC showed that the reaction of the raw materials was complete, cooled to room temperature, and added 22ml of glacial acetic acid. Continue to stir for 10 minutes, add 1000ml of water and 400ml of ethyl acetate, stir, and separate layers. The aqueous phase was extracted once with ethyl acetate and the organic phases were combined. Dry over anhydrous magnesium sulfate. Evaporate to dryness under reduced pressure and separate on a silica gel column to obtain 90 g of pure compound of formula 3.

[0022] 2. [2R-(2α, 3β, 5α)]-5-succinimide-3-(benzyloxy)-2-[(ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com