Glass substrate for magnetic disc, method for manufacturing such glass substrate, magnetic disc and method for manufacturing such magnetic disc

A technology for glass substrates and manufacturing methods, which is applied in the direction of manufacturing base layers, disc carrier manufacturing, magnetic recording layers, etc., can solve problems such as cumbersomeness and damage to the main surface, achieve easy grinding, large objects to be ground, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

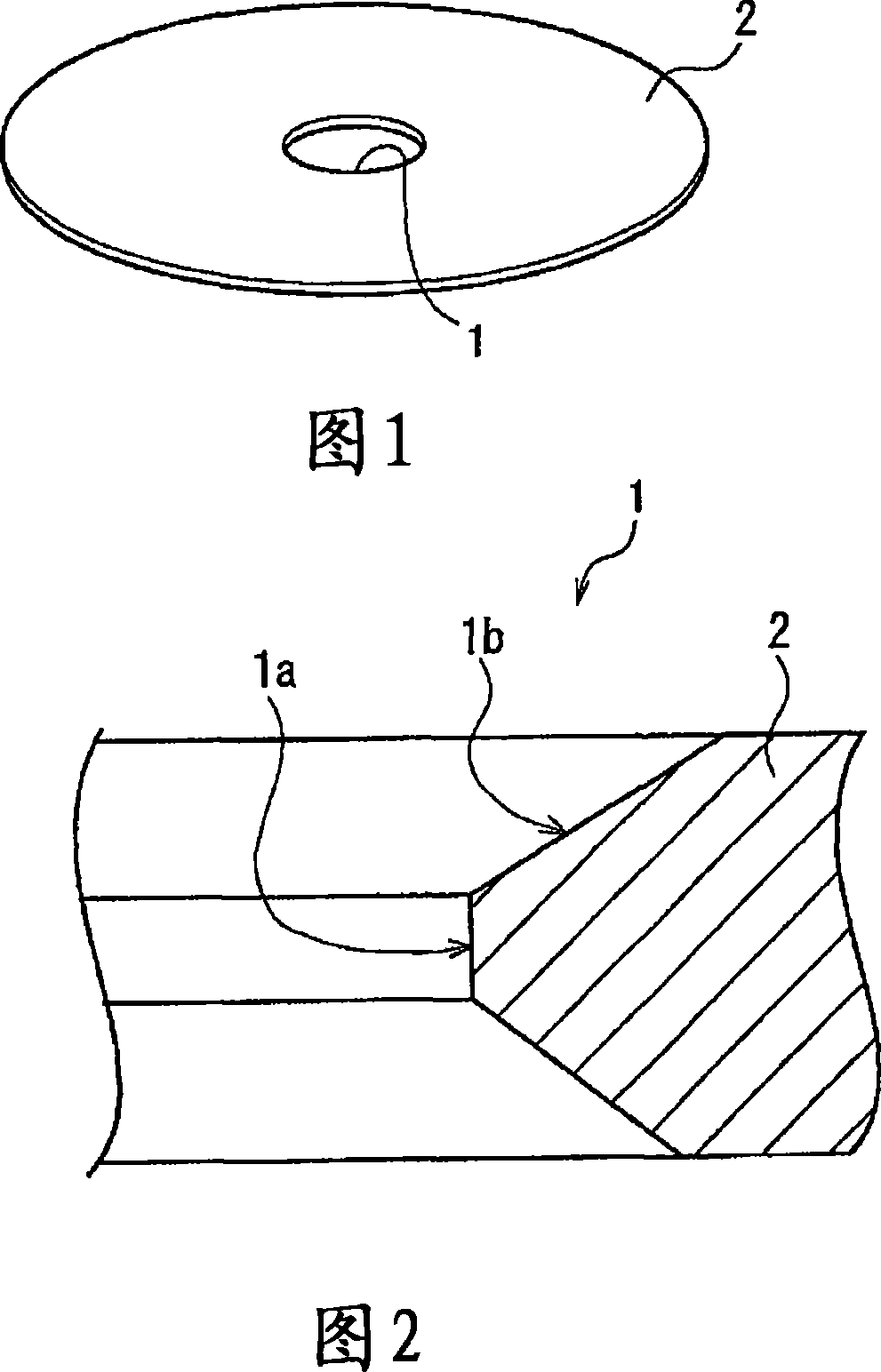

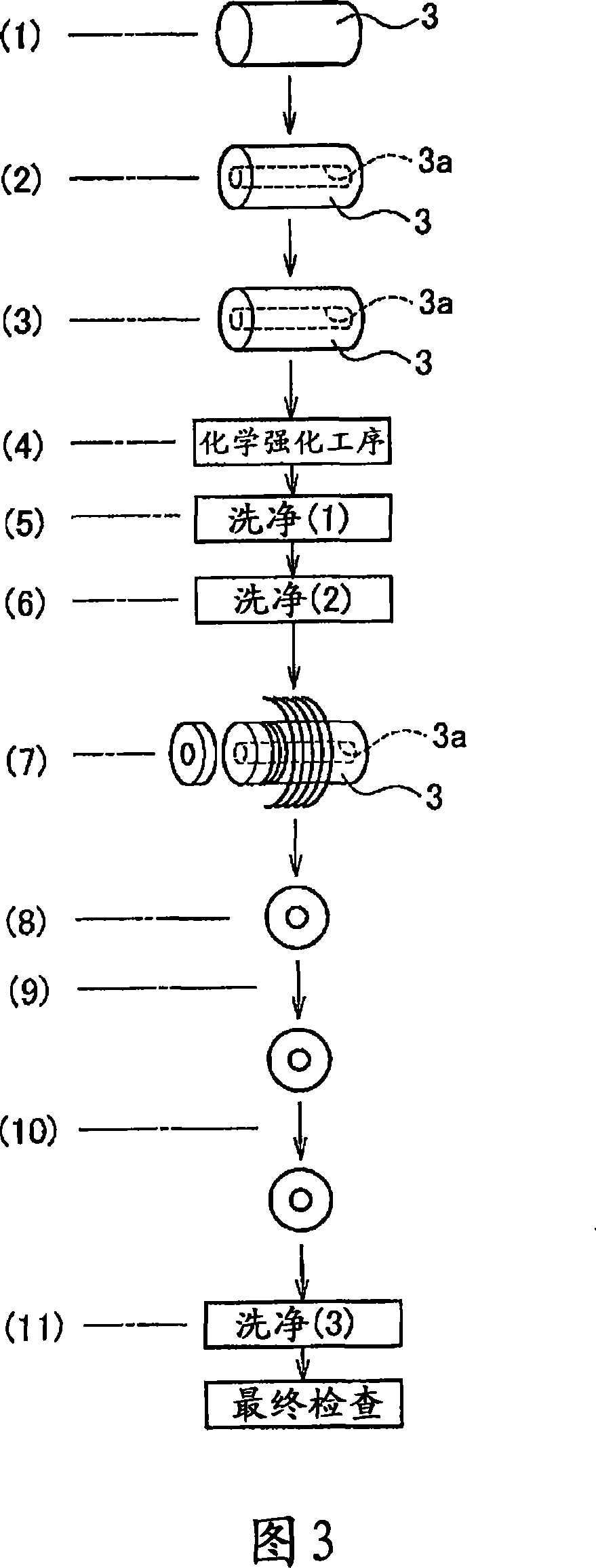

[0113] In this Example 1, the glass substrate for magnetic discs was manufactured through the following process.

[0114] (1) The process of obtaining a cylindrical glass base material

[0115] In this example, a glass base material made of aluminosilicate glass was prepared.

[0116] The size of the glass base material was 28.6 mm in diameter.

[0117] (2) The process of forming a center hole in the glass base material

[0118] Next, a center hole is formed along the center axis of the glass base material 3 . The inner diameter of the central hole is 5.9 mm.

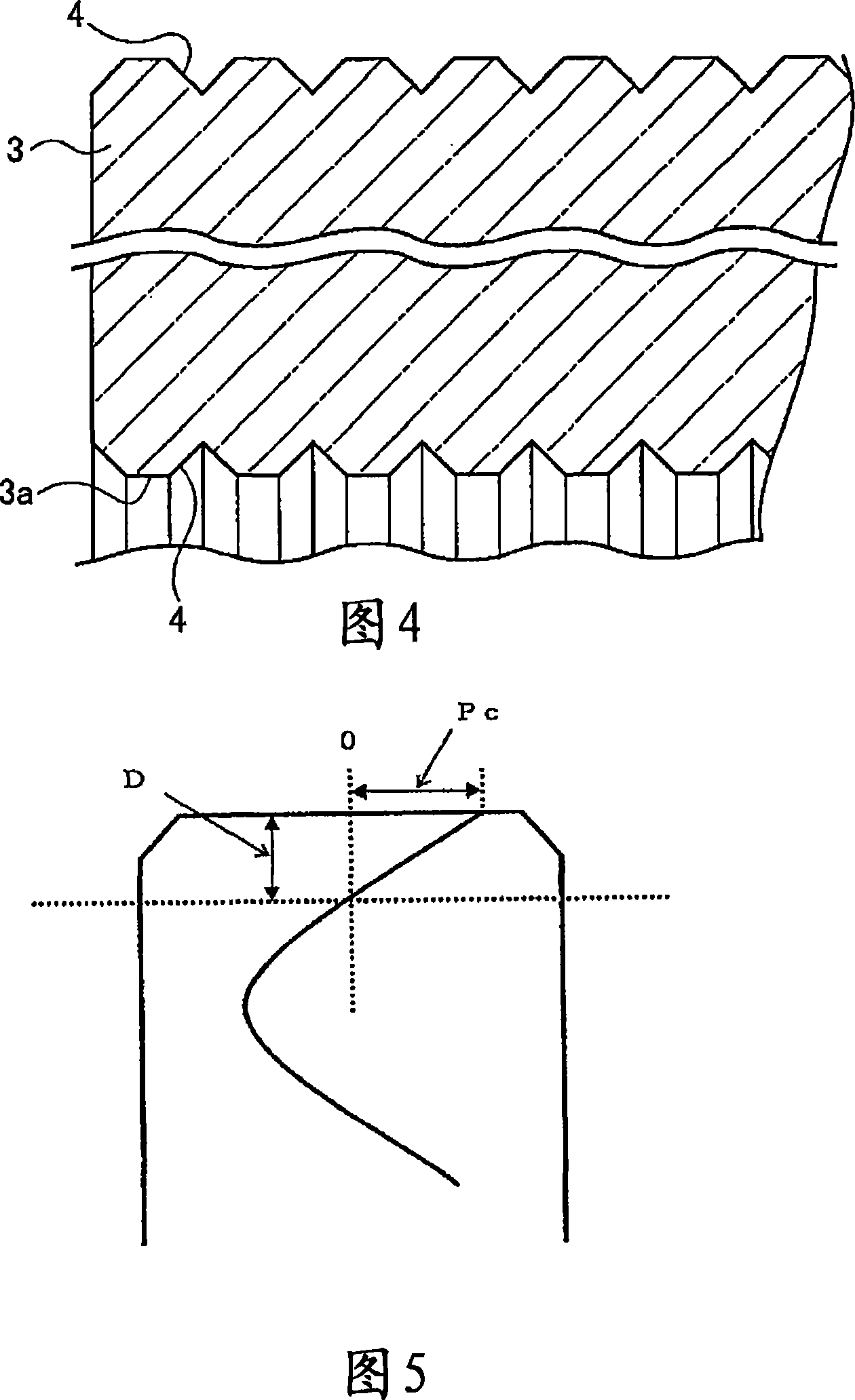

[0119] (3) The process of grinding (mirror finishing) the side surfaces of the inner and outer peripheries of the glass base material

[0120] The outer peripheral side (peripheral surface) of the glass base material was mirror-polished by a polishing brush polishing method. At this time, as the abrasive grains, a slurry (free abrasive grains) containing cerium oxide abrasive grains is used.

[0121] Next, the inn...

Embodiment 2

[0165] In this Example 2, a magnetic disk was manufactured by the following process using the glass substrate for magnetic disks produced in said Example 1.

[0166] On the two main surfaces of the above-mentioned glass substrate for magnetic disks, a Ni-Ta alloy first base layer, a Ru second base layer, Co-Cr-Pt-B Alloy magnetic layer, hydrogenated carbon protective layer. Next, an ethylene-modified polytetrafluoroethylene-based lubricating layer was formed by a dipping method. In this way, a magnetic disk for perpendicular magnetic recording was obtained.

[0167] In the obtained magnetic disk, it was confirmed that no defects due to foreign matter occurred on films such as the magnetic layer. In addition, no collision (collision between the head and the protrusions on the surface of the magnetic disk) and damage (collision between the head and the protrusions on the surface of the magnetic disk) were found during the sliding test. Furthermore, in the playback test using ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com