Power luminous diode packaging structure

A technology of light-emitting diodes and packaging structures, which is applied to electrical components, electric solid-state devices, circuits, etc., can solve the problems of complex manufacturing process, unsatisfactory heat dissipation effect, and high production cost, and achieves low cost of accessories, improved heat dissipation effect and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

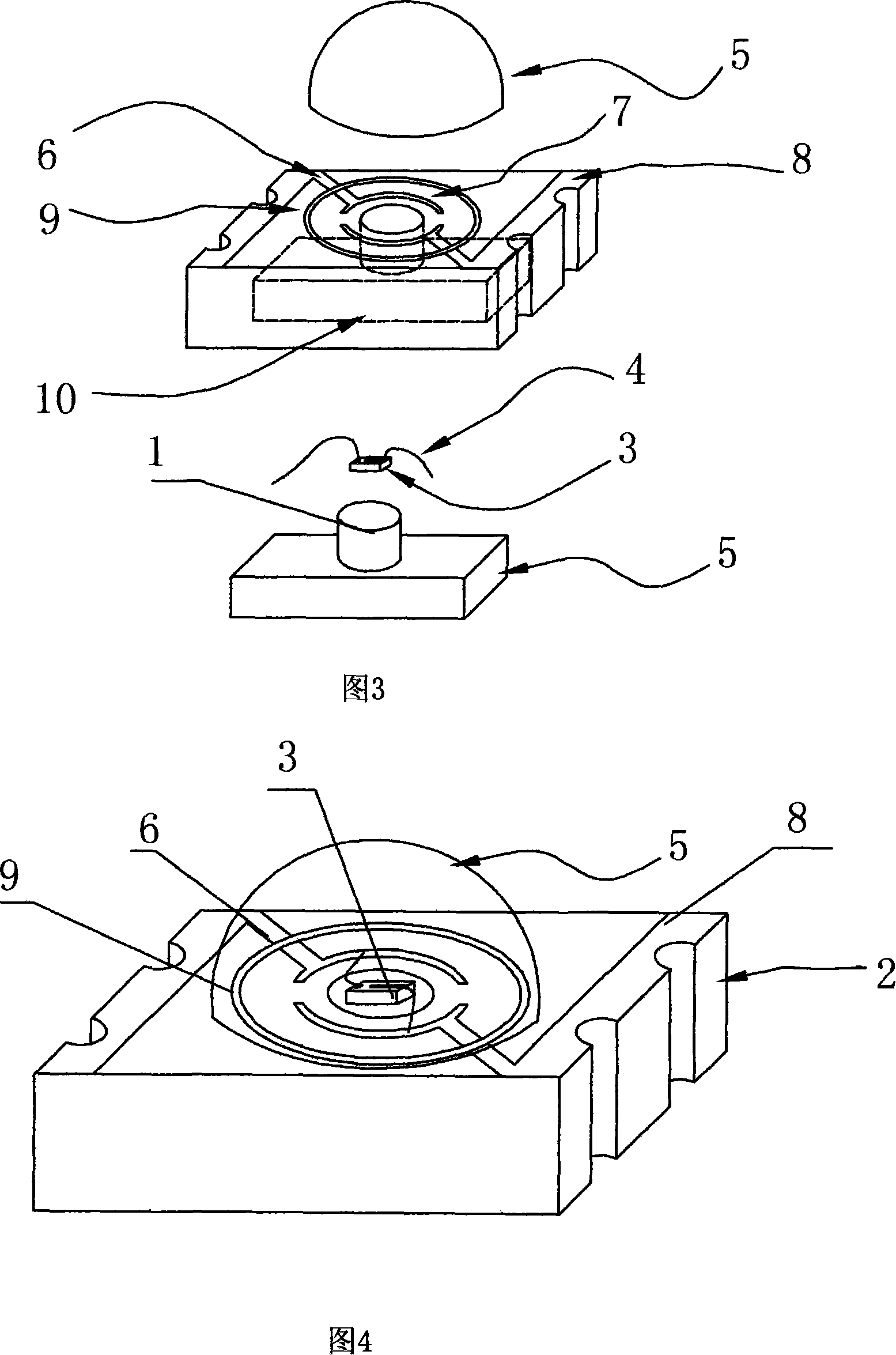

[0037] 1) Preparation of the circuit board: complete the circuit corrosion on the surface of the circuit board 2, the circuit is divided into metal circuit 6, internal metal electrode 7, external metal electrode 8 several parts, internal metal electrode 7 and external metal electrode 8 are connected through metal circuit 6, Then the choke ring 9 on the surface of the circuit board is prepared, and the choke ring 9 surrounds the upper surface of the heat sink 1 on which the LED chip 3 is placed and the internal electrodes 7 .

[0038] 2) Preparation of the counterbore structure: the machining of the counterbore structure 10 is completed through the hole forming process of the circuit board.

[0039] 3) Preparation of the heat sink: the forming of the heat sink 1 is completed.

[0040] 4) Assembly: the heat sink 1 is embedded inside the counterbore structure 10 of the circuit board 2 .

[0041] 5) Chip placement: the chip 3 is placed on the heat sink 1 .

[0042] 6) Lead conne...

Embodiment 2

[0045] The implementation example 2 of the power light-emitting diode structure of the present invention is as follows:

Embodiment 110,1。 Embodiment Synthetic ,, 1 ,,。 Embodiment approach

[0048] 1) Preparation of the upper circuit board: after the circuit printing of the upper circuit board 11 is completed, the through-hole structure 12 is prepared.

[0049] 2) Preparation of the lower circuit board: after the circuit printing of the lower circuit board 13 is completed, the through-hole structure 12' is prepared, and the through-hole has an inverted tapered structure.

[0050] 3) Heat sink preparation: complete the forming of the heat sink 1'.

[0051] 4) Assembly: sandwich the heat sink between the upper and lower circuit boards 11, 13, and then compound the two circuit boards together. The lower surface of the upper circuit board and the upper surface of the lower circuit board have electrodes connected to each other.

[0052] As a further illustration of this example, the heat sink is a circular, elliptical, square, or rectangular terraced structure. Figure 7 and Figure 8 respectively list different heat sink structures with the lower half being circular or e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com