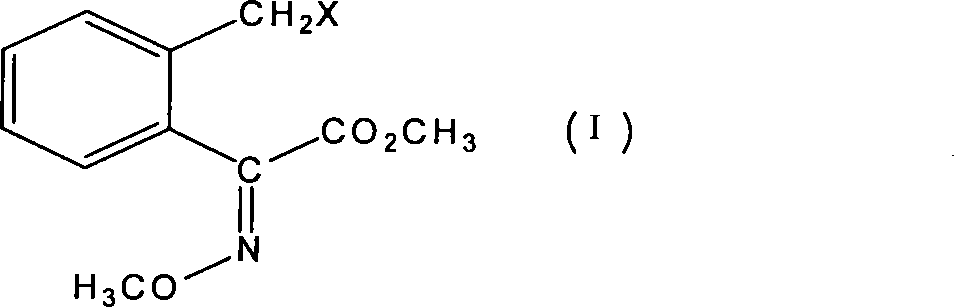

Method for preparing bactericidal agent intermediate (E)-2-(2'-chloromethyl)phenyl-2-methoxy imino methyl acetate

A technology of methyl methoxyiminoacetate and o-methylol benzoic acid lactone is applied in the field of preparation of formula intermediates, and can solve the problem of device blockage, unsuitability, and interference with distillation and purification of o-chloromethyl benzoyl chloride and other problems to achieve the effect of improved safety, high yield and reduced risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

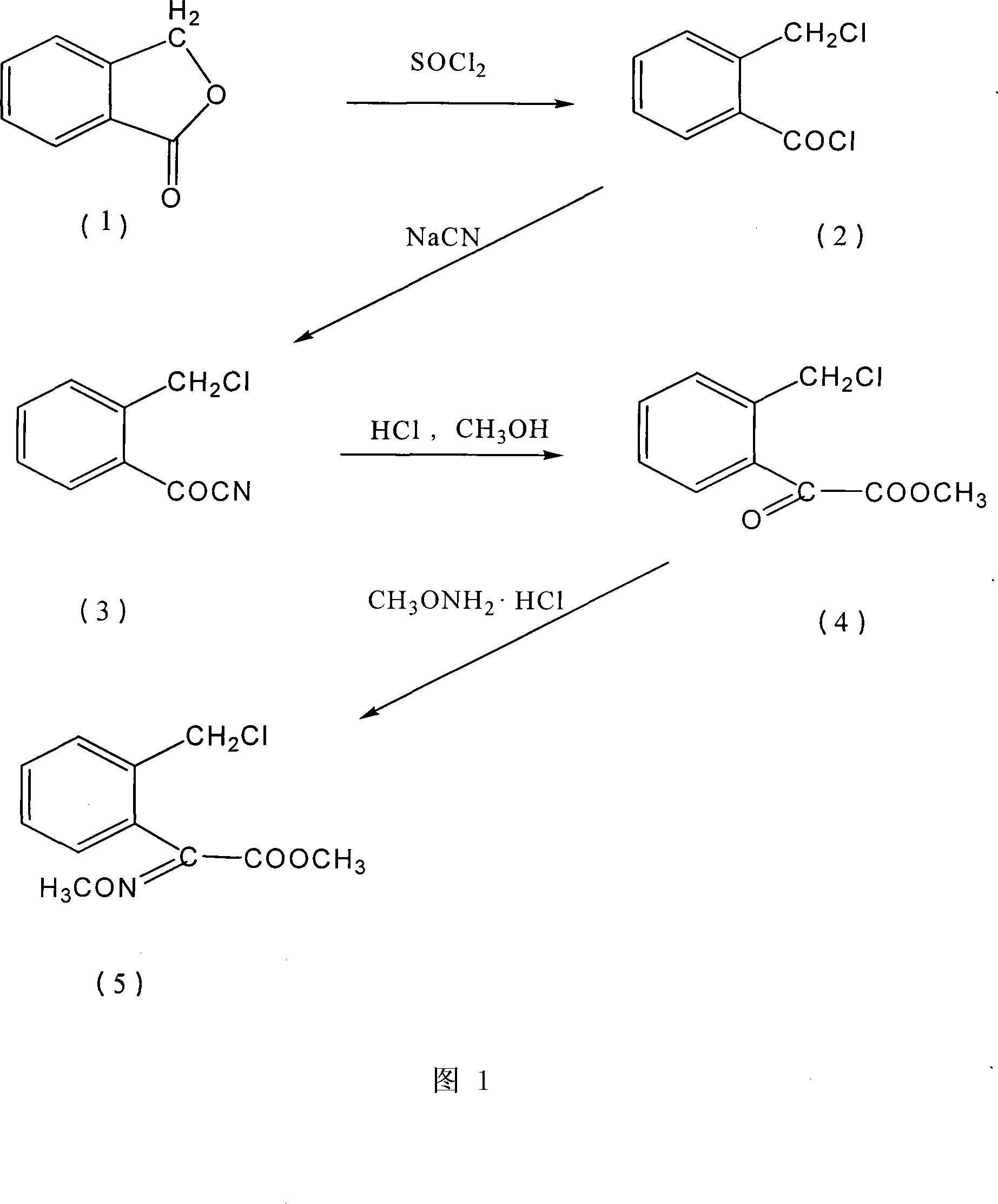

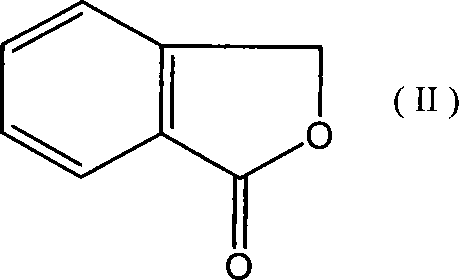

[0039] Embodiment 1, the preparation method of agricultural fungicide chemical intermediate (E)-2-(2'-chloromethyl)phenyl-2-methoxyiminoacetic acid methyl ester, with reference to Fig. 1:

[0040] Step 1, the preparation of o-chloromethylbenzoyl chloride

[0041] 271g (99%, 2.0mol) o-hydroxymethylbenzoic acid lactone (phthalide), 10.5g (99%, 0.1mol) trimethyl borate, 28.5g (99% 0.1mol) triphenylphosphine oxide were added to In a 500ml reaction flask, heat it to 130°C under stirring, and add 324.5g (99%, 2.7mol) of thionyl chloride dropwise to the reaction flask for 3 to 5 hours. After the addition is complete, the mixture is reacted at 130°C for 5 hours. The reaction effluent was distilled under reduced pressure to obtain 366.4 g of the product; the purity was 98% (GC), and the yield was 95%.

[0042] Step 2, the preparation of o-chloromethyl benzoyl cyanide

[0043]Add 120g (98%, 2.4mol) of sodium cyanide and 470ml of water into a 3000ml reaction flask, dissolve the sodium ...

Embodiment 2

[0050] Embodiment 2 is basically the same as Embodiment 1, but has the following changes:

[0051] Step 1, the preparation of o-chloromethylbenzoyl chloride

[0052] Add 271g (99%, 2.0mol) o-hydroxymethylbenzoic acid lactone (phthalide), 3.8g (99%, 0.06mol) boric acid, 17g (99%, 0.06mol) triphenylphosphine oxide to a 500ml reaction bottle 324.5 g (99%, 2.7 mol) of thionyl chloride was added dropwise to the reaction flask in 3 to 5 hours, and after the addition was completed, the mixture was reacted at 130°C for another 5 hours, and the reaction discharge Distillation under reduced pressure gave 366 g of the product; the purity was 97% (GC), and the yield was 94%.

[0053] Step 2, the preparation of o-chloromethyl benzoyl cyanide

[0054] Add 162.5g (96%, 2.4mol) of potassium cyanide and 460ml of water into a 3000ml reaction flask, dissolve potassium cyanide into an aqueous solution under stirring, then add 1544g of toluene, 23g (99%, 0.1mol) of benzyl trichloride Ethyl ammo...

Embodiment 3

[0055] Embodiment 3 is basically the same as Embodiment 1, but has the following changes:

[0056] Step 1, the preparation of o-chloromethylbenzoyl chloride

[0057] 271g (99%, 2.0mol) o-hydroxymethylbenzoic acid lactone (phthalide), 10.5g (99%, 0.1mol) trimethyl borate, 26.5g (99%, 0.1mol) triphenylphosphine were added to In a 500ml reaction flask, heat it to 130°C under stirring, and add 324.5g (99%, 2.7mol) of thionyl chloride dropwise to the reaction flask for 3 to 5 hours. After the addition is complete, the mixture is reacted at 130°C for 5 hours. The reaction effluent was distilled under reduced pressure to obtain 370.5 g of the product; the purity was 97% (GC), and the yield was 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com