Petroleum water coke slurry combustion apparatus and burning method thereof

A combustion device and combustion method technology, applied in the direction of combustion method, burner, combustion type, etc., can solve the problems of difficult ignition, high ignition temperature requirements, narrow fuel selection range, etc., to achieve easy control, avoid coking, and get rid of excessive fuel consumption dependent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

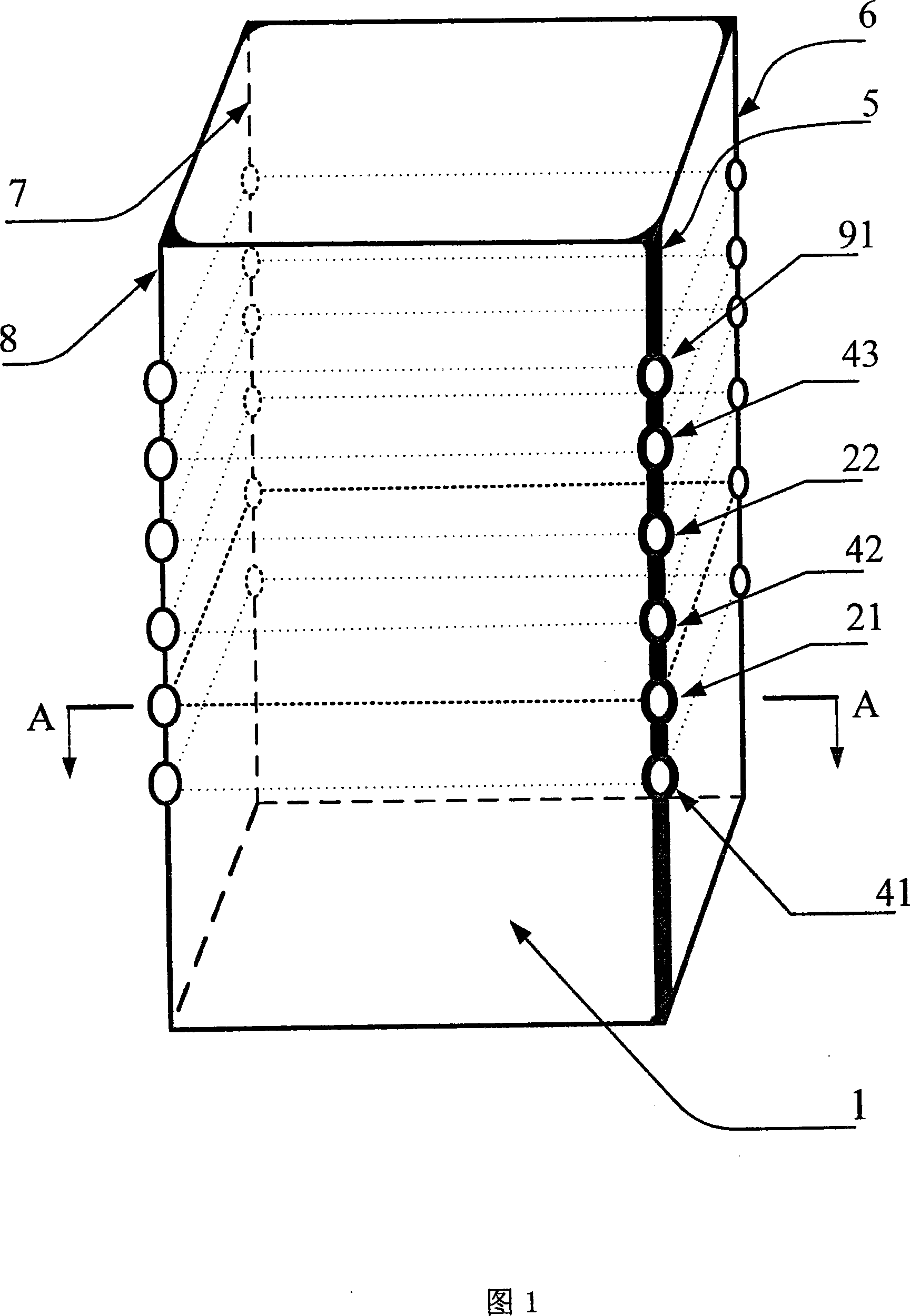

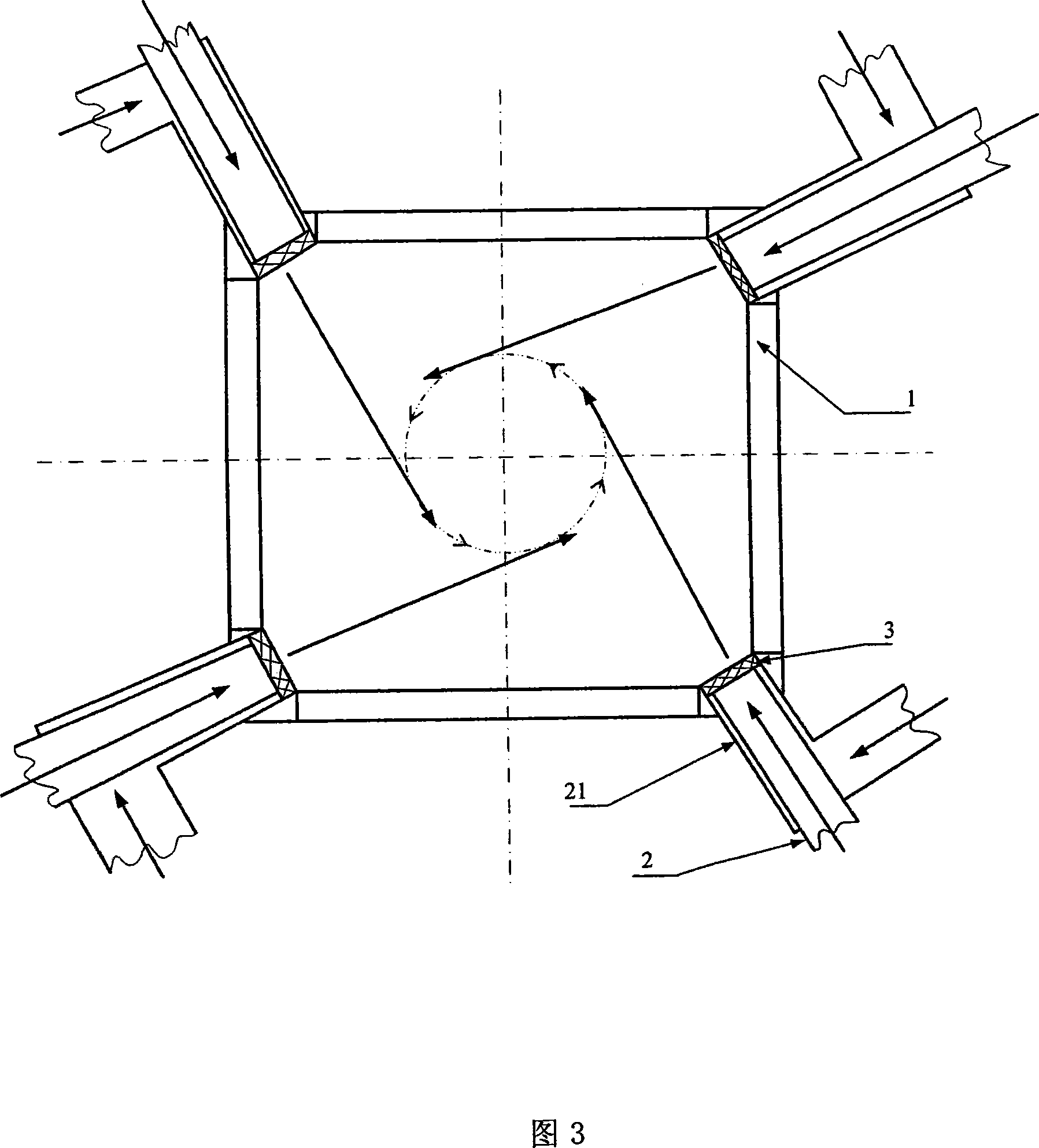

[0032] According to the petroleum coke slurry combustion device and its combustion method of the first embodiment of the present invention, as shown in Figure 1, this is a petroleum coke slurry combustion device and its combustion method for a power plant boiler burning petroleum coke slurry A specific embodiment of the above, wherein the petroleum water coke slurry combustion device is provided with a straight-through three-fuel burner four-corner inlet structure on the boiler body 1, that is, the boiler body 1 is provided with four rows of evenly distributed inlets Setting positions 5, 6, 7, 8, and access setting positions 5, 6, 7, and 8 are all equipped with independent access ports, ports that can be inserted into refinery waste gas spray guns, and ports that can be inserted into slurry and oil spray guns, and are on the same floor The plane corresponds to the same type of inlet, wherein the outlet of the inlet that can be inserted into the slurry and oil spray gun is shown...

Embodiment 2

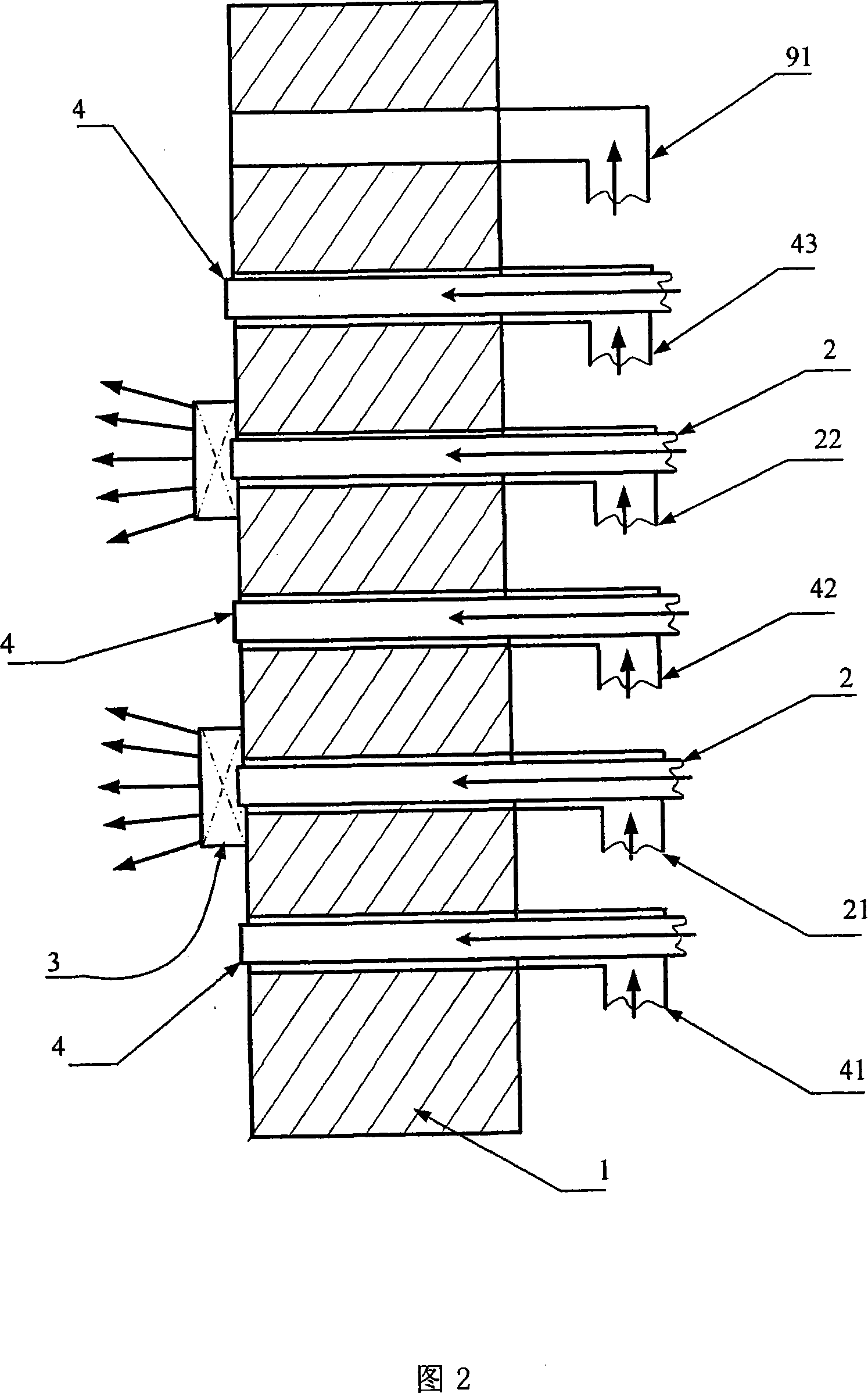

[0036] The petroleum coke slurry combustion device and its combustion method according to the second embodiment of the present invention are shown in Figure 2, which is a petroleum coke slurry combustion device and its combustion method for power plant boilers burning petroleum coke slurry The specific embodiment of the above, wherein the oil water coke slurry combustion device is set in each column of the inlet setting position of the boiler furnace body 1, and is sequentially provided with an independent inlet 91, an inlet 43 that can be inserted into the refining waste gas spray gun, and an inlet that can be inserted The inlet 22 of the slurry and oil spray gun, the inlet 42 that can be inserted into the refinery exhaust gas spray gun, the inlet 21 that can be inserted into the slurry and oil spray gun, and the inlet 41 that can be inserted into the oil refinery exhaust gas spray gun. The independent inlet 91 is sprayed into the pressurized preheated air swirl in the combust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com