Method for wastewater comprehensive utilization of saponin production

A technology for producing wastewater and saponin, applied in chemical instruments and methods, phosphorus compounds, non-metallic elements, etc., can solve the problems of high concentration, unacceptable for enterprises, large wastewater treatment capacity, etc., and achieves low operating cost, wastewater containing The effect of reducing salt content and reducing the difficulty of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

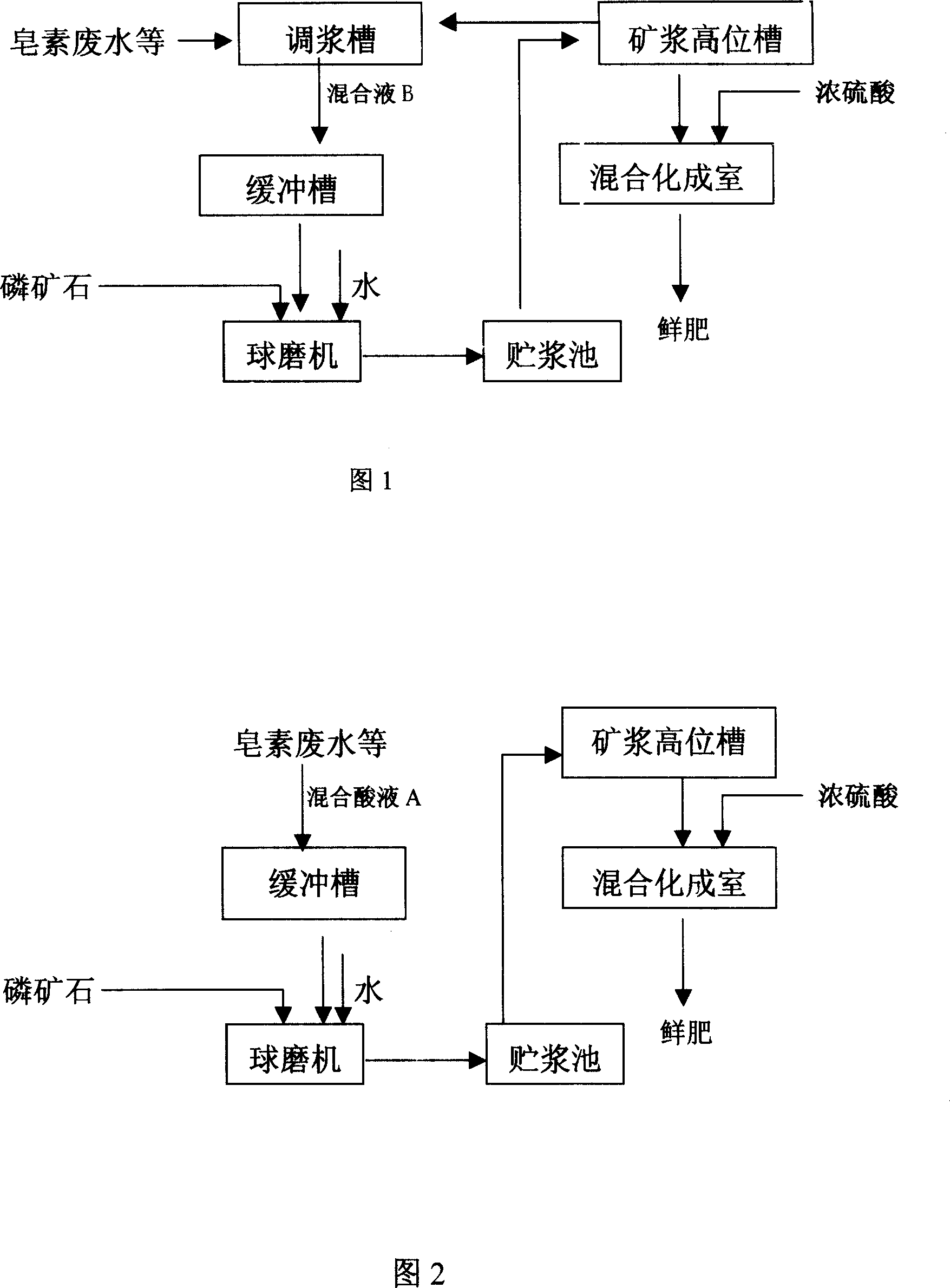

Embodiment 1

[0029] The hydrolyzate of turmeric hydrolyzed by hydrochloric acid is filtered or centrifuged to obtain high-concentration wastewater and filter cake. The water content of the filter cake is 80%. The filter cake is carried out in the same way as the traditional process. After three times of rinsing and filtration, the eluate is combined into low-concentration wastewater with a concentration of COD=5000mg / L. The wastewater is neutralized by alkali to pH6~8, and N and P nutrients are supplemented. Anaerobic reactor (anaerobic filter), the COD removal rate of wastewater reaches 70%. The COD concentration of the effluent is 1500mg / L, and then treated in the aerobic aeration tank, the effluent reaches COD=100mg / L and is discharged.

[0030] Get 50 kilograms of above-mentioned high-concentration waste water, add auxiliary agent (tall oil pine resin) 260g, combine 10 kilograms of low-concentration waste water, and 10 kilograms of fluosilicic acid produced in superphosphate productio...

Embodiment 2

[0032] Filter or centrifuge the hydrolyzate of fendilong hydrolyzed by sulfuric acid to obtain high-concentration wastewater and filter cake. The filter cake has a water content of 72%. The filter cake is carried out in the same way as the traditional process. After rinsing and filtering, the eluate is combined into low-concentration wastewater with a concentration of COD=8000mg / L. The wastewater is neutralized by alkali to PH=7, and N and P nutrients are supplemented. Flow plate anaerobic reactor, the COD removal rate of wastewater reaches 78%. The COD concentration of the effluent reaches 1760mg / L, and after oxidation ditch treatment, the effluent COD reaches 90mg / L and is discharged.

[0033] Take 10 kg of the above-mentioned high-concentration waste water, add 1 g of auxiliary agent (tall oil fatty acid), combine 20 kg of low-concentration waste water, and 20 kg of fluosilicic acid produced in the superphosphate production process, and pour it into the pulping tank and fr...

Embodiment 3

[0035] The hydrolyzate of turmeric hydrolyzed by sulfuric acid is filtered or centrifuged to obtain high-concentration wastewater and filter cake. The water content of the filter cake is 68%. The filter cake is carried out in the same way as the traditional process. After rinsing and filtering, the eluate is combined into low-concentration wastewater with a concentration of COD=8000mg / L. The wastewater is neutralized by alkali to PH=7, and N and P nutrients are supplemented. Oxygen digester, the COD removal rate of wastewater reaches 78%. The effluent COD concentration reaches 1760mg / L, and after SBR treatment, the effluent COD reaches 90mg / L and is discharged.

[0036]Take 70 kg of the above-mentioned high-concentration wastewater, add 60 g of oleic acid as an auxiliary agent, and put it into the slurry mixing tank to carry out preliminary reaction with the pulp returned from the pulp high level tank. Control the water content of the mixed liquid in the slurry tank to 65%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com