Foreign body removing device of the vessel cover

A foreign matter removal and container cover technology, which is applied in the direction of cleaning methods, packaging, and packaging protection using gas flow, to achieve the effect of improving the effect of foreign matter removal and reliable removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

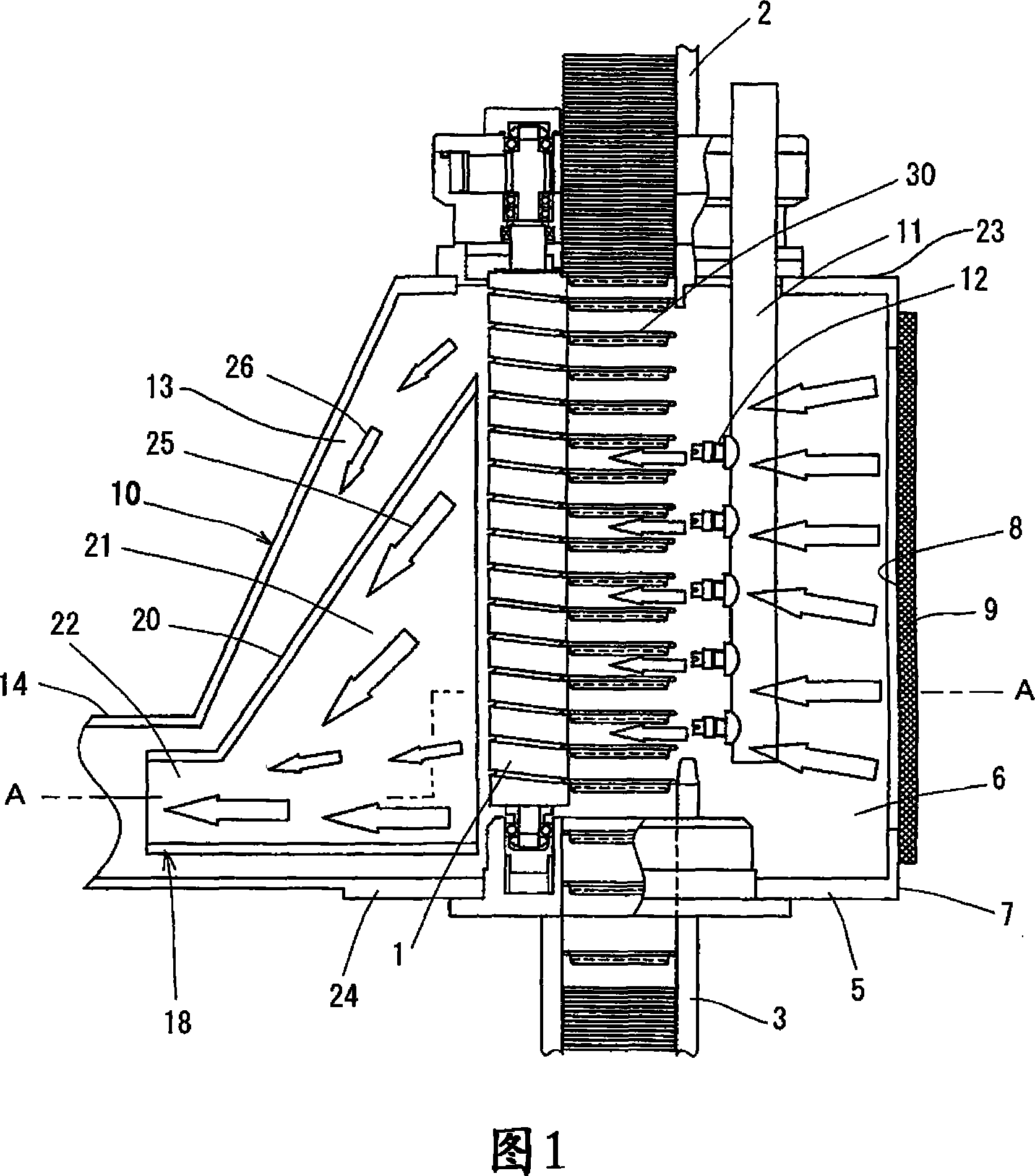

Embodiment 1

[0042] Using the foreign matter removal device for container caps shown in FIG. 1 , the following experiments were conducted to confirm the state of removal of foreign matter. As an experiment, 10 can lids were used as a group, wherein each lid was attached with 60 aluminum scraps on its surface and back, and put into the upstream side chute, and pulled out from the downstream side chute, and The number of foreign substances remaining on the front and back of each cap was counted. As the air injection condition from the air nozzle at this time, the injection pressure is set to 1.0kg / cm 2 , The total injection volume is 1000L / min, and the suction volume of the suction passage is set to 6000L / min for the experiment. As a result, as shown in Table 2, there was no residual aluminum dust attached to the surface, and only one lid with one aluminum dust attached to the back was observed. Thus, the aluminum dust was almost completely removed, and it was difficult to completely remove...

Embodiment 2

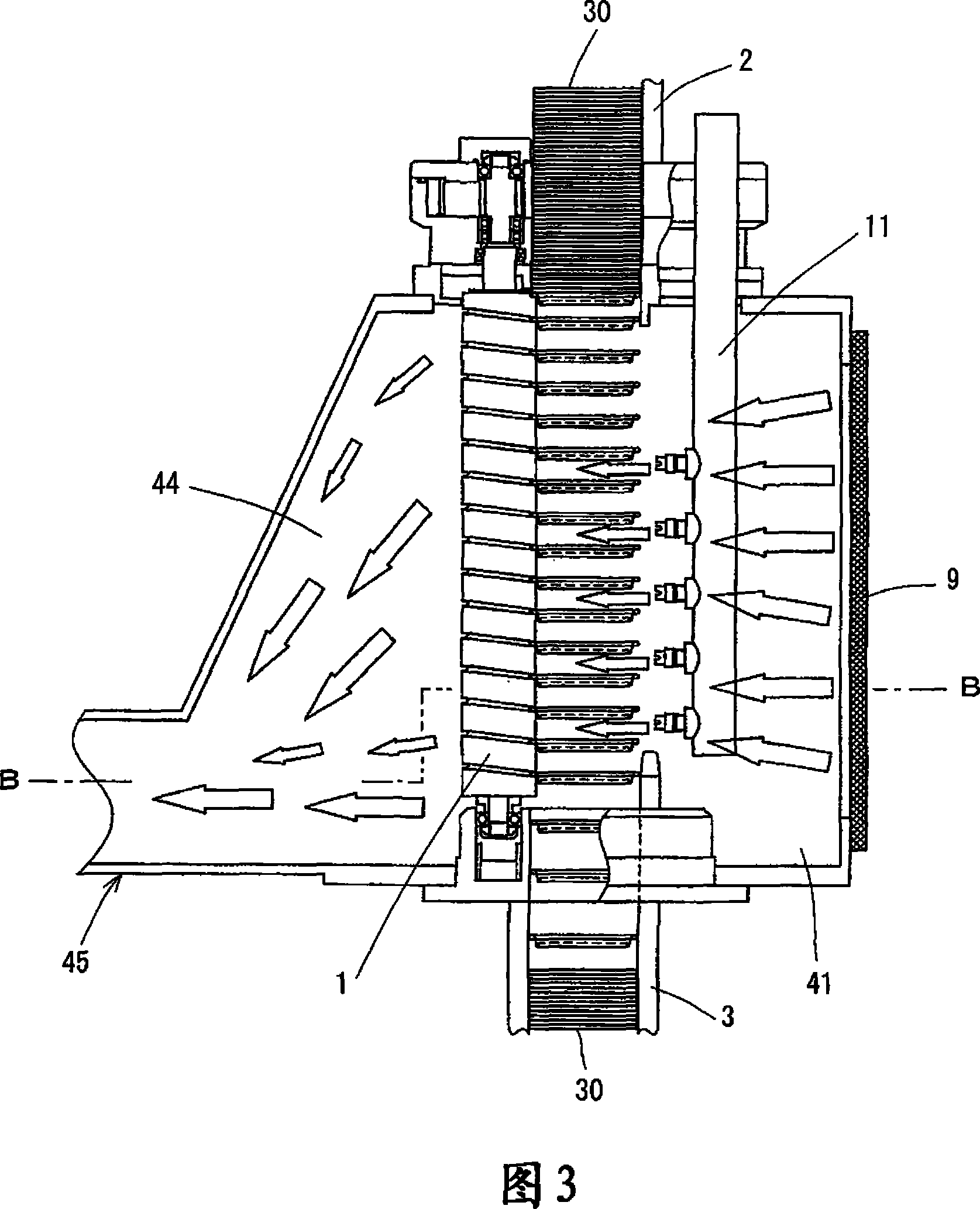

[0046] In addition, experiments were carried out under the same conditions as in Example 1 using the apparatus shown in FIGS. 3 and 4 . The results are shown in Table 3. As a result, it was confirmed that the devices shown in FIGS. 3 and 4 were mostly removed, although the removal rate was lower than that of Example 1. According to the above results, it can be confirmed that although it is most effective to set the local concentration passage, the clearance rate also becomes high due to the situation of Example 2 compared with the comparative example shown in Table 1, and it is usually not as carried out in the experiment. Since a large amount of foreign matter adheres to the cover, it can be sufficiently used for practical use.

[0047] table 3

[0048] 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com