Activation method for membrane electrode of fuel cell

A technology of fuel cell membrane and activation method, which is applied in the field of activation of fuel cell membrane electrodes and can solve the problems of long activation time and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

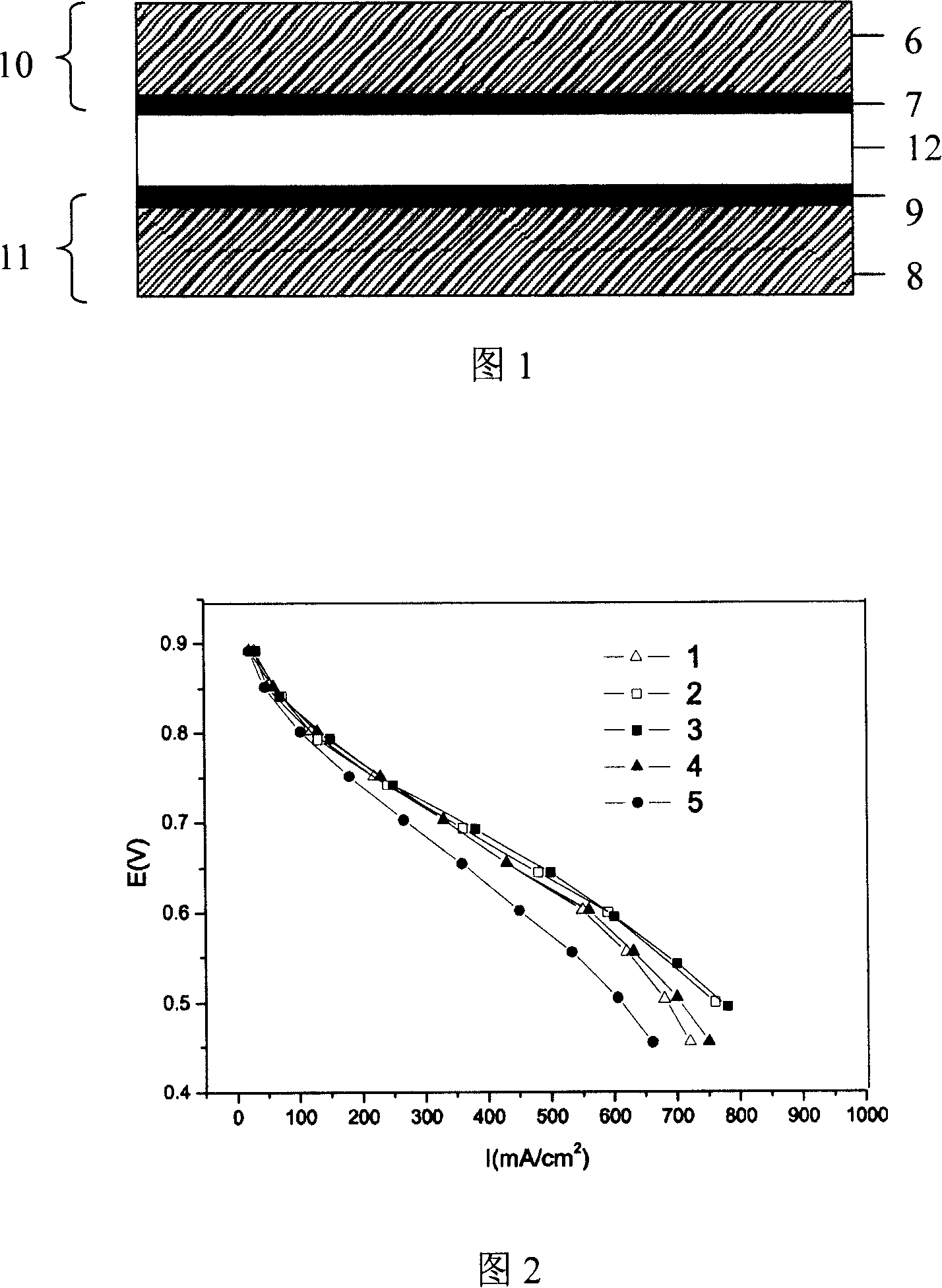

[0028] This embodiment illustrates the activation method of the fuel cell membrane electrode provided by the present invention

[0029] 1. Preparation of Membrane Electrode

[0030] (1) 0.2 parts by weight of carbon black (Vulcan XC72R, Cabot company) and 0.1 parts by weight of PTFE emulsion (FR303A, Shanghai Sanaifu New Material Co., Ltd.) with a solid content of 60% by weight, and 10 parts by weight of deionized water are mixed , ultrasonically dispersed for 30 minutes to obtain a carbon dispersion, and then the carbon dispersion was coated on carbon paper (TGP-H-90, Toray Company), and the weight gain of the carbon paper after drying at 100°C was 1 mg / cm 2 , and then placed in a high-temperature oven at 350 ° C for 20 minutes to obtain a gas diffusion layer;

[0031] (2) 0.2 parts by weight of Pt / C catalyst (Hispec8100, product of Johnson Matthey Company) with platinum loading of 47.7% by weight and 2 parts by weight of nafion dispersion (DE520, product of DUPONT Company) ...

Embodiment 2

[0038] This embodiment illustrates the activation method of the fuel cell membrane electrode provided by the present invention

[0039] Prepare and activate the membrane electrode according to the method of Example 1, the difference is that the temperature of the battery is controlled to 80 ° C, and a sliding rheostat with a resistance value of 2 ohms is connected in series between the external power supply and the fuel cell, sliding the sliding rheostat, adjusting the external The current of the power supply stabilizes the voltage of the fuel cell at 0.6 volts, discharges the fuel cell for 30 minutes, then continues to adjust the current of the external power supply to stabilize the voltage of the fuel cell at 0.4 volts, discharges the fuel cell for 30 minutes, and then disconnects the external power supply, Make the fuel cell stop discharging, leave it on hold for 1 minute, and then repeat the above steps 5 times, then the discharge current density of the fuel cell is stable ...

Embodiment 3

[0041] This embodiment illustrates the activation method of the fuel cell membrane electrode provided by the present invention

[0042] The membrane electrode was prepared and activated according to the method of Example 1, except that the temperature of the battery was controlled at 55° C., and the temperature of the humidified hydrogen and humidified air was 50° C. And directly connect the potentiostat (Shenzhen Yishite Electronics Co., Ltd., DC regulated power supply) to the two ends of the fuel cell, adjust the voltage of the constant voltage potentiometer to stabilize the voltage of the fuel cell to 0.6 volts, and discharge the fuel cell 10 minutes, then continue to adjust the voltage of the constant voltage potentiometer so that the voltage of the fuel cell is 0.4 volts, discharge the fuel cell for 30 minutes, then disconnect the external power supply, stop the discharge of the fuel cell, leave it for 2 minutes, and then adjust the constant voltage potential again The vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com