Glass fiber reinforced plastics grille with conducting function and manufacturing method thereof

A glass fiber reinforced plastic and grid technology, applied in the direction of slender elements, building materials, building elements, etc., can solve the problems of difficult requirements, non-conductive properties, and difficult to meet the requirements of glass fiber reinforced plastic grid, and achieve reliable and good product quality. Conductive properties, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

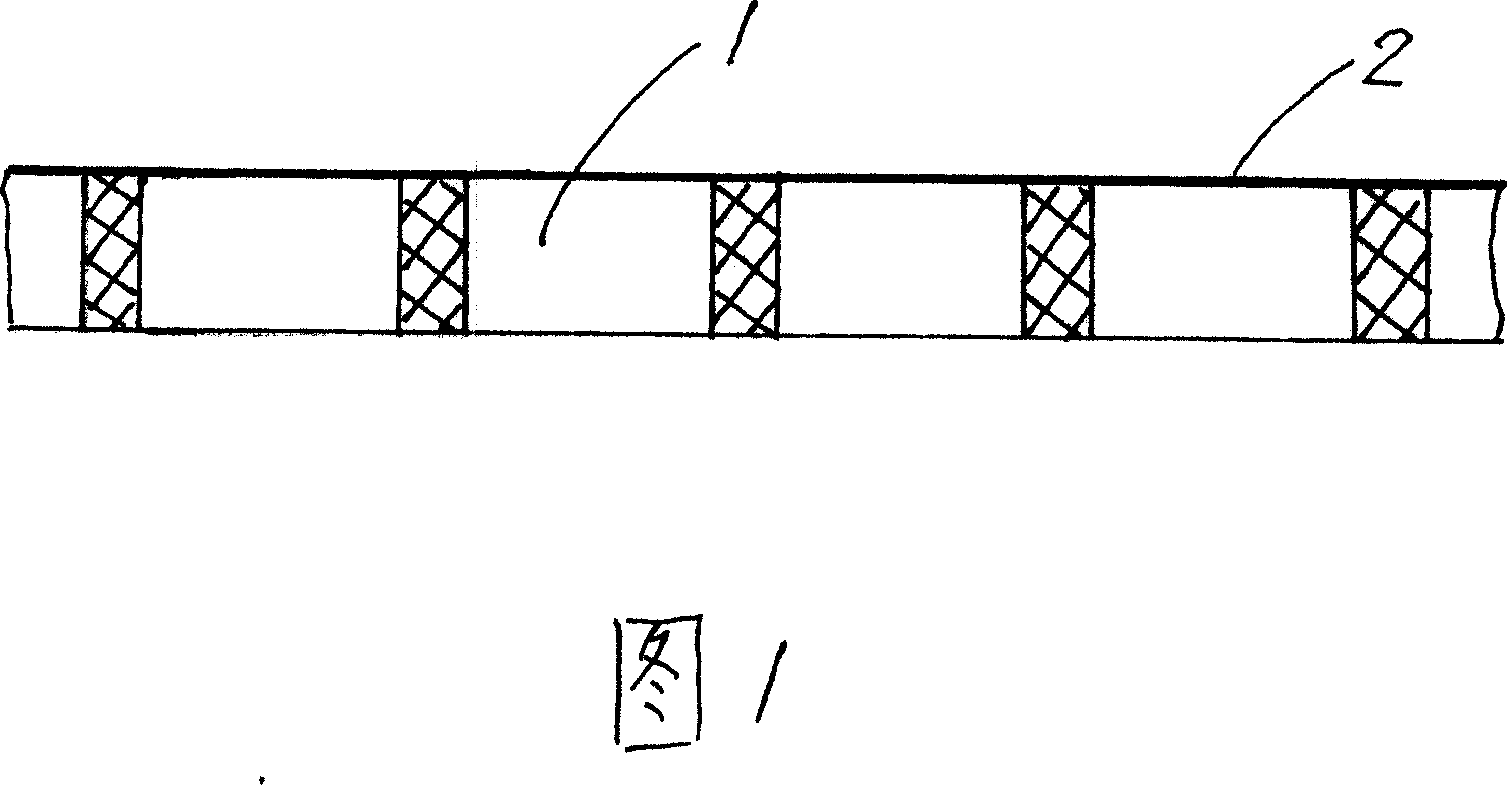

Embodiment 1

[0031] With reference to accompanying drawing 1, the FRP grating with conductive function of the present invention comprises the grid body 1 with resin as base material, glass fiber yarn as reinforcing material, and conductor 2 solidified therewith; said conductor 2 Depending on the usage environment, the thickness of the thickness can be a layer in the structure of the grid body 1, or it can be the entire structure of the grid body 1. The conductor 2 in this embodiment is a layer. The conductor 2 is a cured product of resin glue, an appropriate amount of carbon powder, an accelerator, and a curing agent, or a cured object of resin glue, an appropriate amount of carbon powder, an accelerator, and a curing agent, and glass fiber yarn as a reinforcing material. The appropriate amount of carbon powder added to the conductor 2 refers to carbon powder whose weight group is: 0.1-20% of the resin content. The appropriate amount of accelerator added to the conductor 2 refers to the ad...

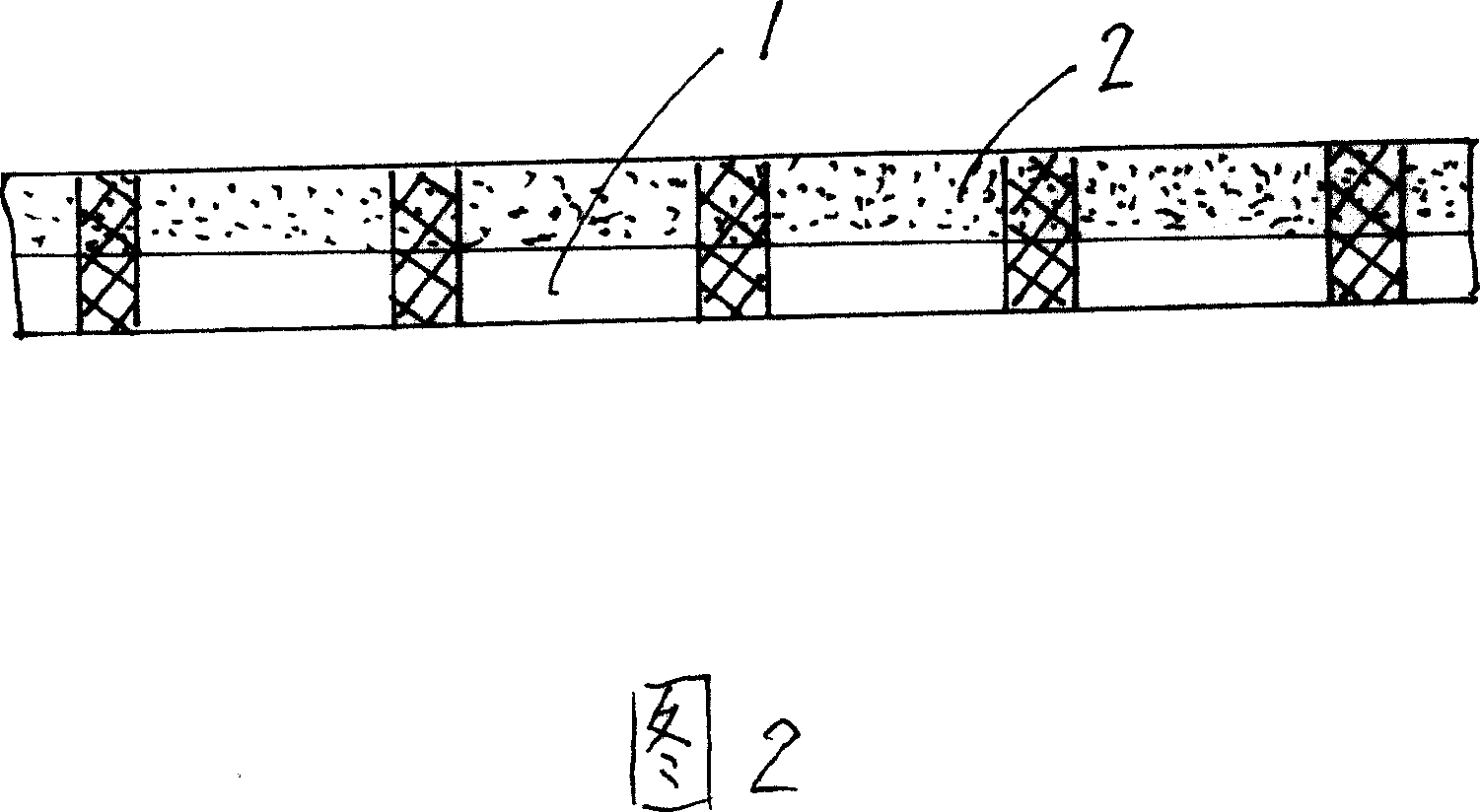

Embodiment 2

[0044] With reference to accompanying drawing 2, the FRP grating with conductive function of this implementation includes a grid body 1 with resin as a base material and glass fiber yarn as a reinforcing material and a conductor 2 solidified therewith. The conductor 2 of this embodiment The thickness is 1 / 2 the thickness of the grid body. The conductor 2 of the present embodiment is a cured product of resin glue and an appropriate amount of carbon powder, accelerator, curing agent, and glass fiber yarn as a reinforcing material. The amount of carbon powder added in the present embodiment is: 1.3% of the resin weight; The amount of cobalt isozincate is: 1.3% of the weight of the resin; the amount of methyl ethyl ketone peroxide added is: 2.6% of the weight of the resin.

[0045] The method for producing the above-mentioned fiberglass grating with conductive function comprises the following steps:

[0046] ① Preheat the special mold and keep the temperature at 42°C;

[0047] ②...

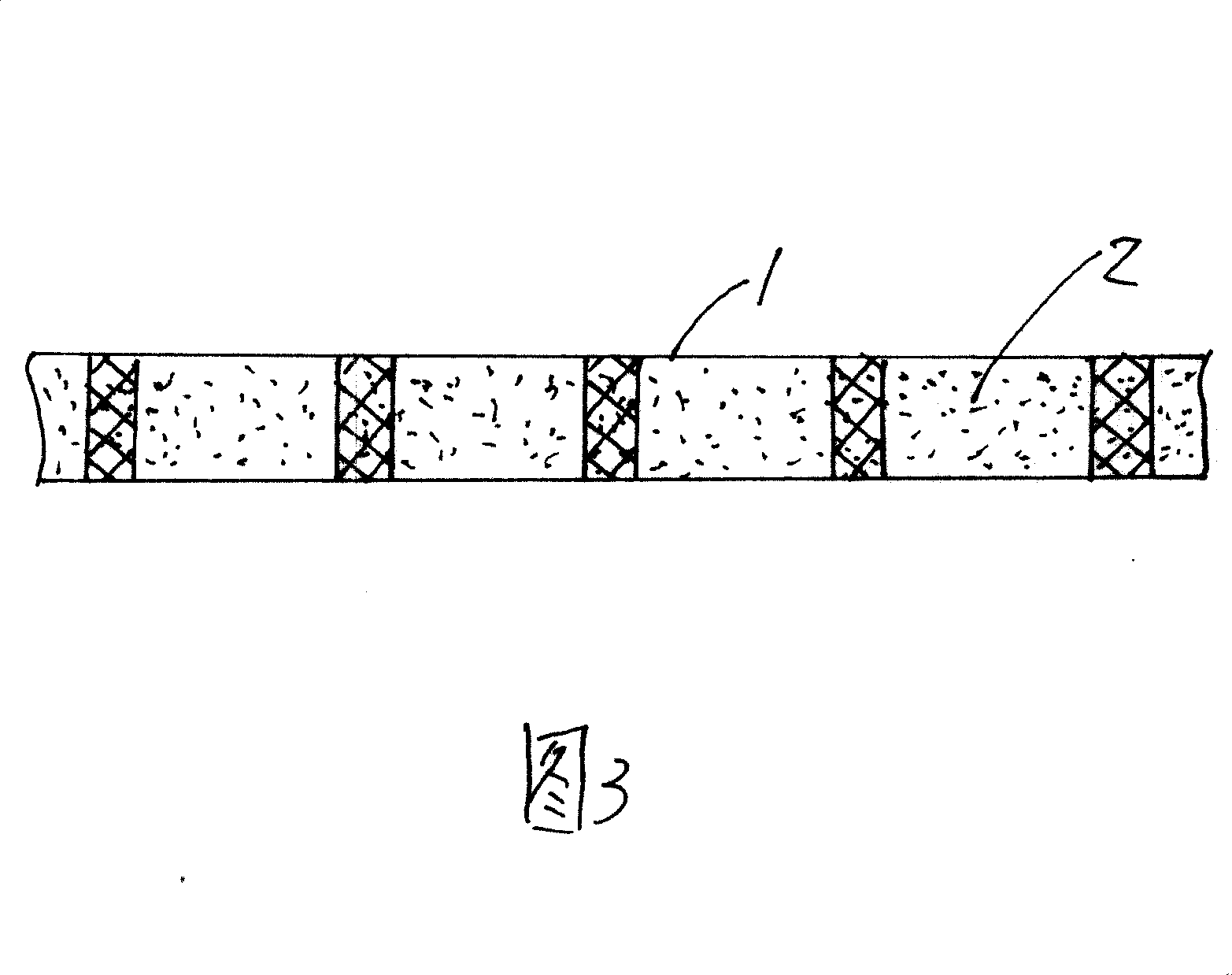

Embodiment 3

[0058]With reference to accompanying drawing 3, the FRP grating with electric conduction function of this implementation includes taking resin as base material, glass fiber yarn as reinforcing material, adding carbon powder, accelerant, solidifying agent solidified conductor 2 in resin glue, this implementation The thickness of the conductor 2 is the total thickness of the grid body. In this embodiment, 10% by weight of carbon powder is added, 2% of cobalt isozincate is used as an accelerator, and 2.8% of methyl ethyl ketone peroxide is used as a curing agent.

[0059] The method for producing the above-mentioned fiberglass grating with conductive function comprises the following steps:

[0060] ① Preheat the special mold and keep the temperature at 35°C;

[0061] ②Take an appropriate amount of resin, add an appropriate amount of toner, accelerator, and curing agent in proportion, and stir evenly;

[0062] ③ casting the resin colloid produced in step ② in the mold cavity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com