Ultrasonic deep-rolling and tumbling integrated surface strengthening device

A surface strengthening and ultrasonic technology, applied in the field of metal surface strengthening, can solve the problems of unfavorable anti-fatigue performance of shear stress, scratches on the workpiece surface, etc., to ensure the adhesion force, reduce friction, and avoid residual shear stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is a detailed description of the embodiments of the present invention:

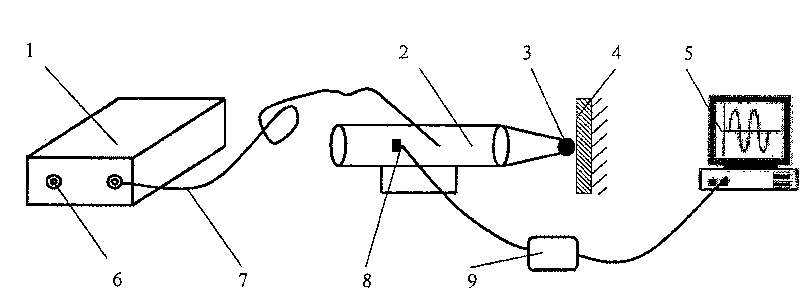

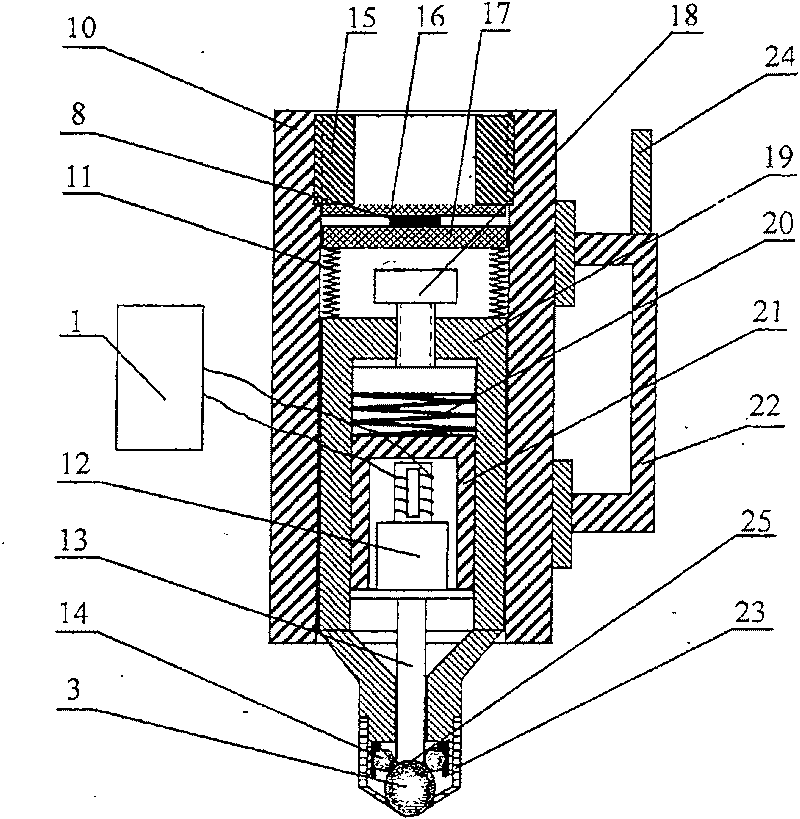

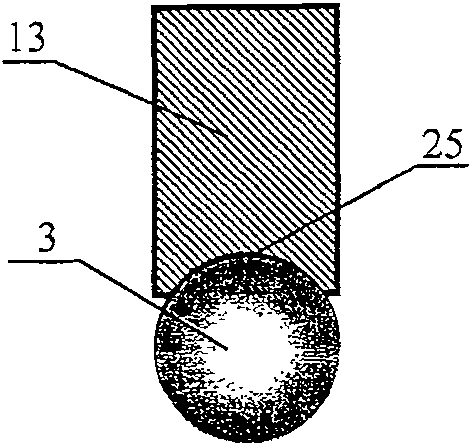

[0038] 220V, 50Hz ordinary commercial power is connected to the ultrasonic generator 1 from the terminal 6, converted into ultrasonic electrical oscillation (18kHz ~ 30kHz) by the ultrasonic generator, and transmitted to the transducer 12 in the ultrasonic deep roller gun 2 through the cable 7, The transducer converts electrical vibration into mechanical vibration of the same frequency, and then amplifies it through the horn 13 and then hits the rolling pin 3 to impact the surface of the workpiece 4 . The horn contacts the rolling pins with the same diameter through the concave spherical surface 25 at its end, on the one hand, it keeps the rolling pins free to roll with low friction, and at the same time minimizes the energy loss of ultrasonic vibration. In the present invention, hard alloy balls with a diameter of φ6 to 12 mm are used as rolling pins, and ordinary GCr15 steel balls o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com