Construction device and construction technique for concrete pipe base

A technology of concrete piles and construction devices, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of adjacent building hazards, difficult control of construction quality, and impact on bearing capacity, and prevent the possibility of piercing loose materials The effect of high reliability, easy control of construction quality, and uniform bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

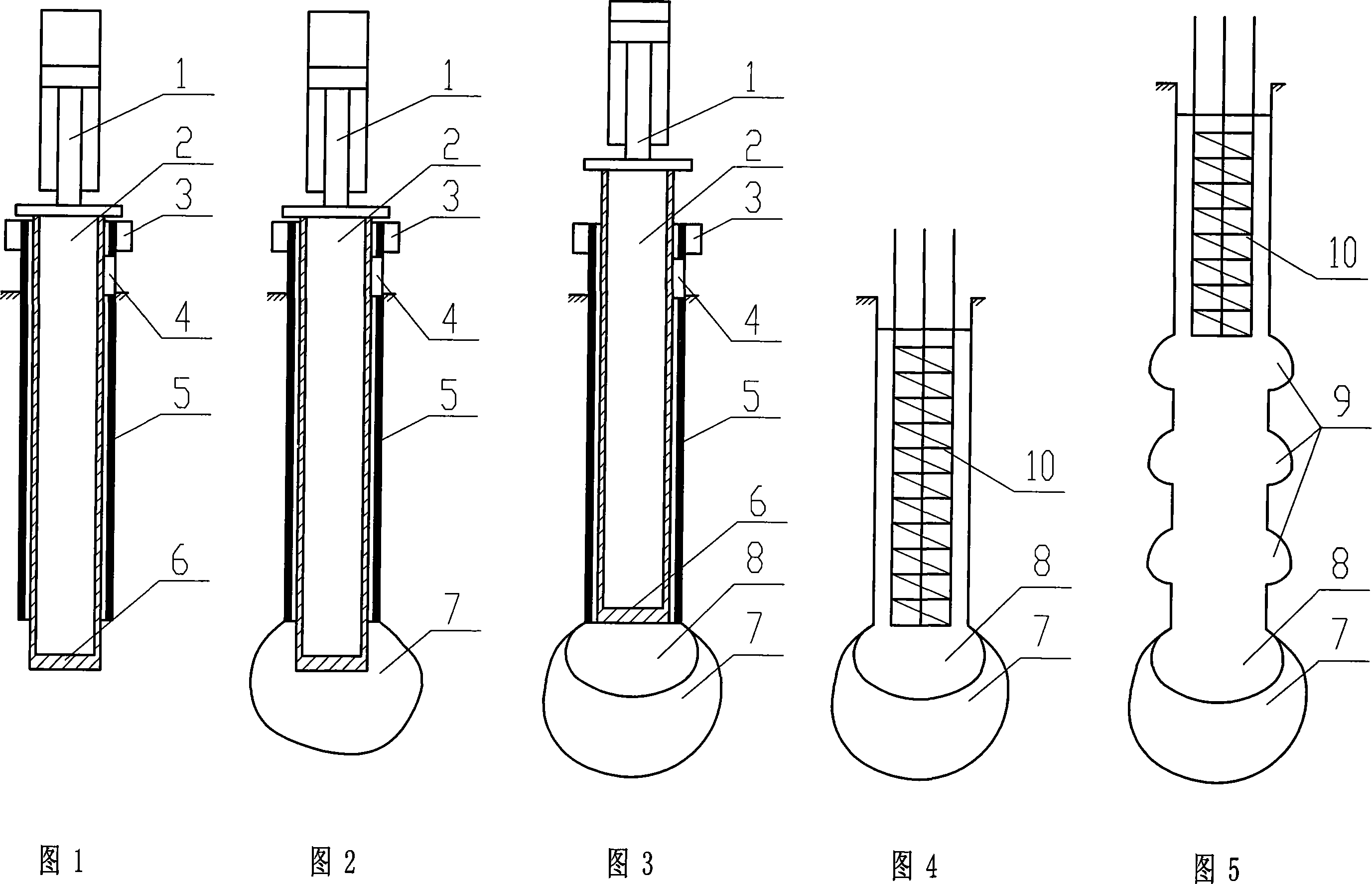

[0037] The technological steps when utilizing the above-mentioned construction device to make the straight tube grouting pile are as follows:

[0038] 1. Press the casing 5 and the inner pipe 2 placed therein into the soil at the pile position step by step with the hydraulic cylinder 1, and reach the design depth, as shown in Figure 1;

[0039]2. Lift the inner pipe 2 and fill in a certain amount of construction waste, such as masonry, tiles, etc., from the feeding port 4 of the casing;

[0040] 3. Put down the inner pipe and press it on the construction waste, use the hydraulic cylinder 1 of the top pressure static pressure pile machine to press the construction waste out of the casing 5, and the construction waste will spread into the soil under the casing;

[0041] 4. Repeat step 2.3 until the reading of the hydraulic gauge is still greater than the design value when the lower end of the inner pipe is pushed out of the casing, stop squeezing the construction waste, and at t...

Embodiment 2

[0045] The process steps when utilizing the construction device of the present invention to make the cast-in-situ pile with large bearing capacity with the middle boss are as follows:

[0046] After step 1 to 5 of embodiment 1 is done well pile tip bulk bearing platform and pile tip solid bearing platform, continue to carry out following technological operation:

[0047] 1. Lift the inner pipe and pour concrete into the casing to another design height;

[0048] 2. Add a certain amount of dry hard concrete into the casing through the feeding port, put down the inner pipe, press it on the above dry hard concrete, lift the casing until the lower end of the casing is as high as the lower end of the inner pipe and stop;

[0049] 3. Use a hydraulic cylinder to press down the inner tube and casing, and the pressing amount is 0.5-1m;

[0050] 4. Repeat steps 2 and 3 until the amount of dry hard concrete reaches the design value, forming a concrete middle boss 9 on the pile body;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com