Method for preparing polycarbonate by fusing ester exchange method and catalyst used for the same

A technology of melt transesterification and polycarbonate, which is applied in the field of catalyst and melt transesterification to prepare polycarbonate, and achieves the effect of good hue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The reaction was carried out in a stirred nickel metal reaction vessel equipped with a non-leakage magnetic coupling drive. The vacuum system is connected to the reactor through the phenol collection bottle and the phenol distillation condenser. The pressure of the reaction system is jointly controlled by the vacuum pump and the nitrogen cylinder introduced into the downstream of the phenol collection bottle. U-type mercury pressure is used for high pressure (atmospheric pressure to 50 mbar). Gauge measurement, low pressure (50 mbar to 1.333 mbar and below) with a Maxwell rotary vacuum gauge. The temperature of the reaction system is heated and controlled by circulating heat transfer oil. A discharge port is provided at the bottom of the reactor.

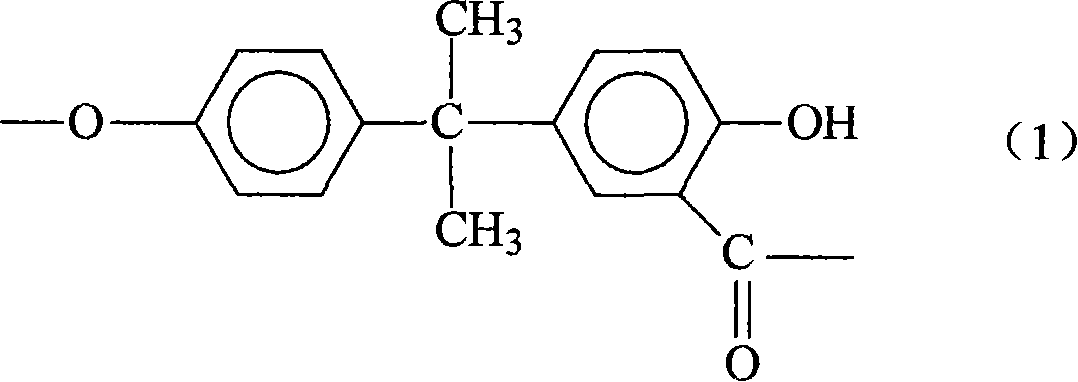

[0064] Add 600.0 g (2.628 mol) of solid bisphenol A (Japan GE Plastics Co., Ltd.), 602.4 g (2.812 mol) of solid diphenyl carbonate (Shanghai Shenju Chemical Factory) and 602.4 g (2.812 mol) of solid diphenyl carbonate / bisphe...

Embodiment 2

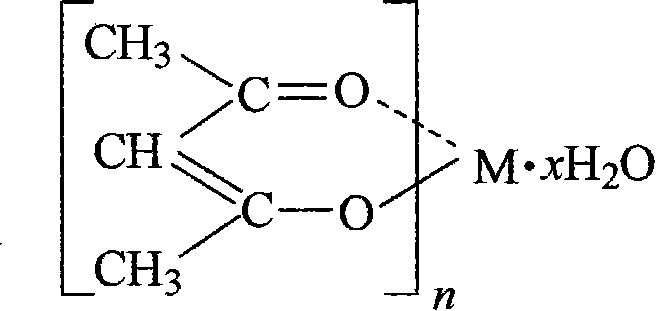

[0081] Except that for 1 mol of bisphenol A, use 1.0×10 -8 mol La(acac) 3 Except for the polymerization catalyst, the same procedure as in Example 1 was performed to prepare polycarbonate.

Embodiment 3

[0083] Except that for 1 mol of bisphenol A, use 1.0×10 -6 mol La(acac) 3 Except for the polymerization catalyst, the same procedure as in Example 1 was performed to prepare polycarbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com