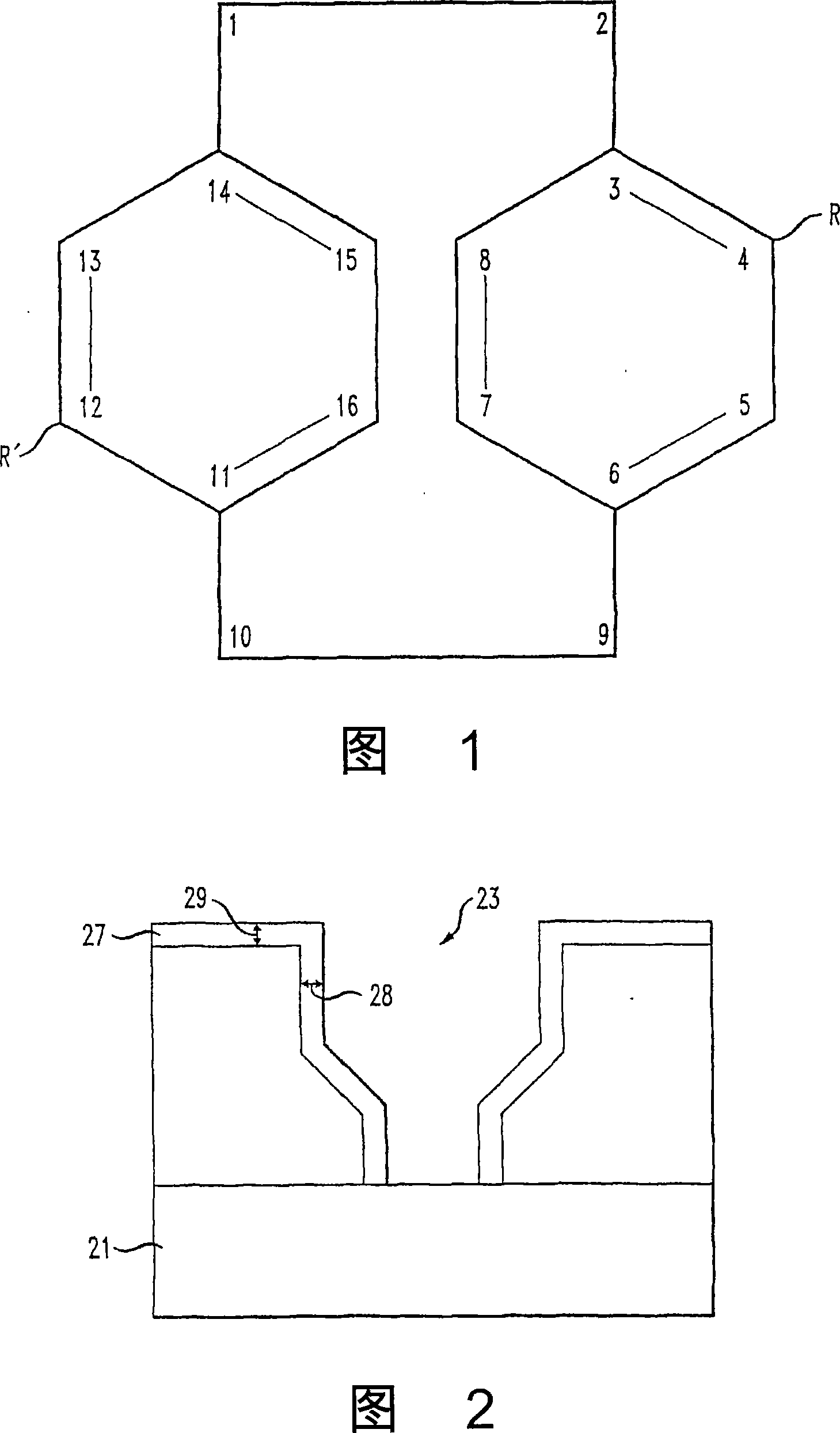

Deposition of polymeric materials and precursors therefor

A technology of polymers and precursors, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of uniformity of difficult adhesive layer, gasification and escape of residual solvents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] About 130 mg of iron powder (average particle size 10 microns) was mixed with 150 mL of chloroform and 130 mL of dichloromethane in a 1000 mL round bottom flask. The mixture was sonicated with a commercial sonicator for 20 minutes, and then 250 ml of dichloromethane and about 17.7 g of [2.2]paracyclophane were added. The whole mixture was stirred open to air with a stir bar and paddle for 2 hours. Gas chromatography of the crude reaction mixture showed 87% yield of 4-bromo[2.2]paracyclane.

[0045] The reaction mixture was washed sequentially with two 150 mL (each) portions of 10% (by weight) aqueous sodium bisulfate, one 150 mL portion of 1 M aqueous NaOH, and one 150 mL portion of saturated aqueous NaCl. After washing, the mixture was washed with anhydrous MgSO 4 dry. The remaining solvent was evaporated using a rotovap at a temperature of 40°C. The residue was recrystallized from hot (50°C) chloroform. Recrystallization had no significant effect on the purity of...

Embodiment 2

[0047] Just before use, 1,4-dioxane was distilled over excess sodium metal and benzophenone ketyl with a reflux condenser under nitrogen. Cesium carbonate was dried at 115°C for 12 hours in a nitrogen atmosphere. Ethynyl-triethylsilane, tris(dibenzylideneacetone)dipalladium(0), and tri-tert-butylphosphine were purchased and used directly.

[0048] Reaction compositions were prepared in 1.5 mL crimp-top vials, each with a magnetic stir bar. To each vial was provided about 0.05 mmol of 4-bromo[2.2]paracyclane prepared and purified as described in Example 1, 0.15 mmol of CsCO 3 , 0.08 mmol of ethynyl-triethylsilane, 0.33 ml of 0.0022N tris(dibenzylideneacetone) dipalladium (0) solution in distilled dioxane, 0.33 ml of 0.188M tri-tert-butyl A solution of phosphine in distilled 1,4-dioxane, and 0.33 mL of a 0.137M solution of tri-tert-butylphosphine in distilled 1,4-dioxane. The sample was heated at 95°C for 3 hours under stirring with a magnetic stir bar. After separation and ...

Embodiment 3

[0050] A solution of 5.0 mmol of 4-(ethylsilaneethynyl)[2.2]p-cycloarane (prepared and purified according to Example 2) in 50 ml of tetrahydrofuran (HPLC grade) was prepared. To this solution was added 10.0 mL of 1.0 M Bu 4 n A solution of NF in THF. The unheated reaction mixture was stirred with a magnetic stir bar under nitrogen atmosphere for about 16 hours. THF was evaporated using a rotary evaporator. According to gas chromatography, the residue was 90% by weight of 4-ethynyl[2.2]paracyclophane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com