Metallic bipolar plate for fuel cells, and fuel cell comprising the same

A metal bipolar plate and fuel cell technology, which is applied to fuel cell parts, fuel cells, battery electrodes, etc., can solve the problems of difficult manufacturing, high manufacturing cost, and unfavorable cost of bipolar plates, and achieve low cost and high efficiency. Effects of corrosion resistance and good battery characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0130] The present invention will now be described more specifically with reference to the examples given below.

[0131] Double-sided bipolar plates of Examples 1R to 17R and Comparative Examples 1R and 2R, and single-sided bipolar plates of Examples 1K to 14K and Comparative Examples 1K to 3K were prepared.

[0132] Specifically, the noble metal layer partially coats the front and back sides of the metal substrate by electroplating, wherein the noble metal layer is formed using the materials shown in Table 1 and Table 2 and has the thickness shown in the table, and the metal substrate uses the materials shown in Table 1 and Table 2. The materials shown in Table 2 were formed and had the thicknesses shown in the table.

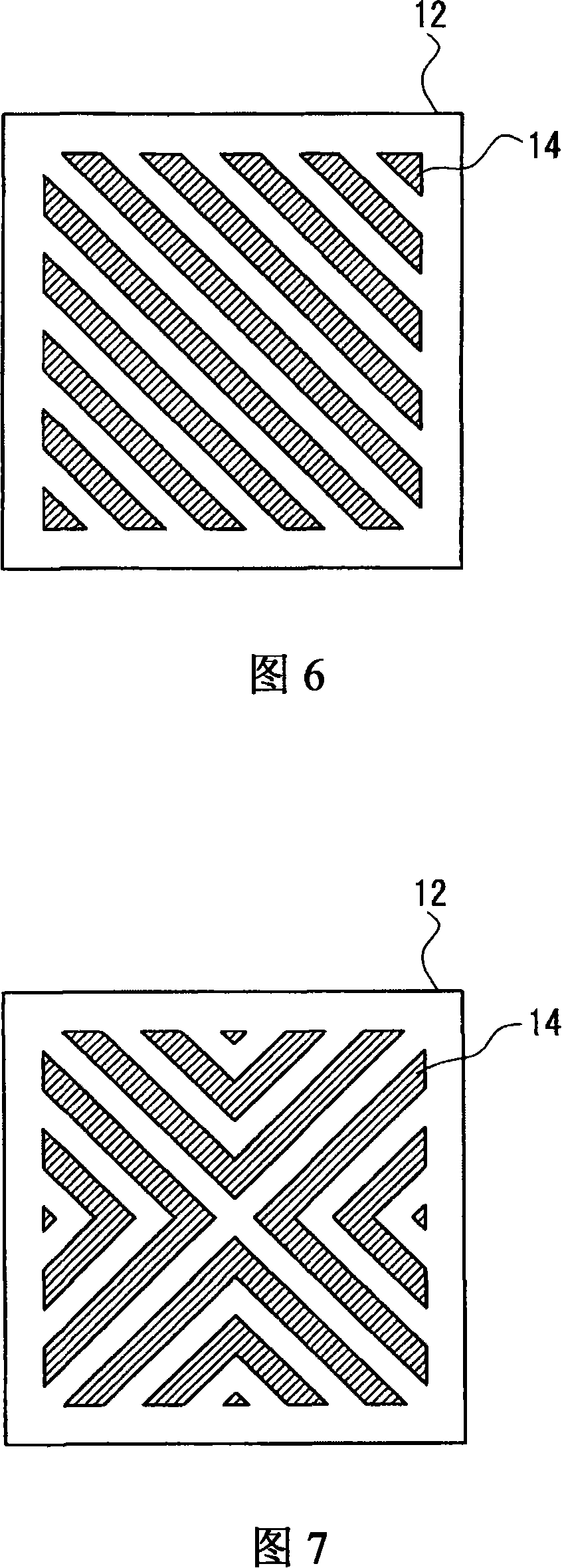

[0133] In this step, considering the shape of the concave-convex part to be formed in the subsequent steps, the electroplating method is designed as follows: the noble metal layer can have the coating area ratio shown in Table 1 and Table 2, and use FIG. 5 or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com