Short barrel extension and recoil type automatic rifle

A technology of automatic rifles and joint sleeves, applied in the field of firearms, can solve the problems of high material and processing technology requirements, inability to adapt to high-power bullets, poor stability and reliability, etc., to improve shooting stability, bullet kinetic energy does not decrease, and guarantees The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

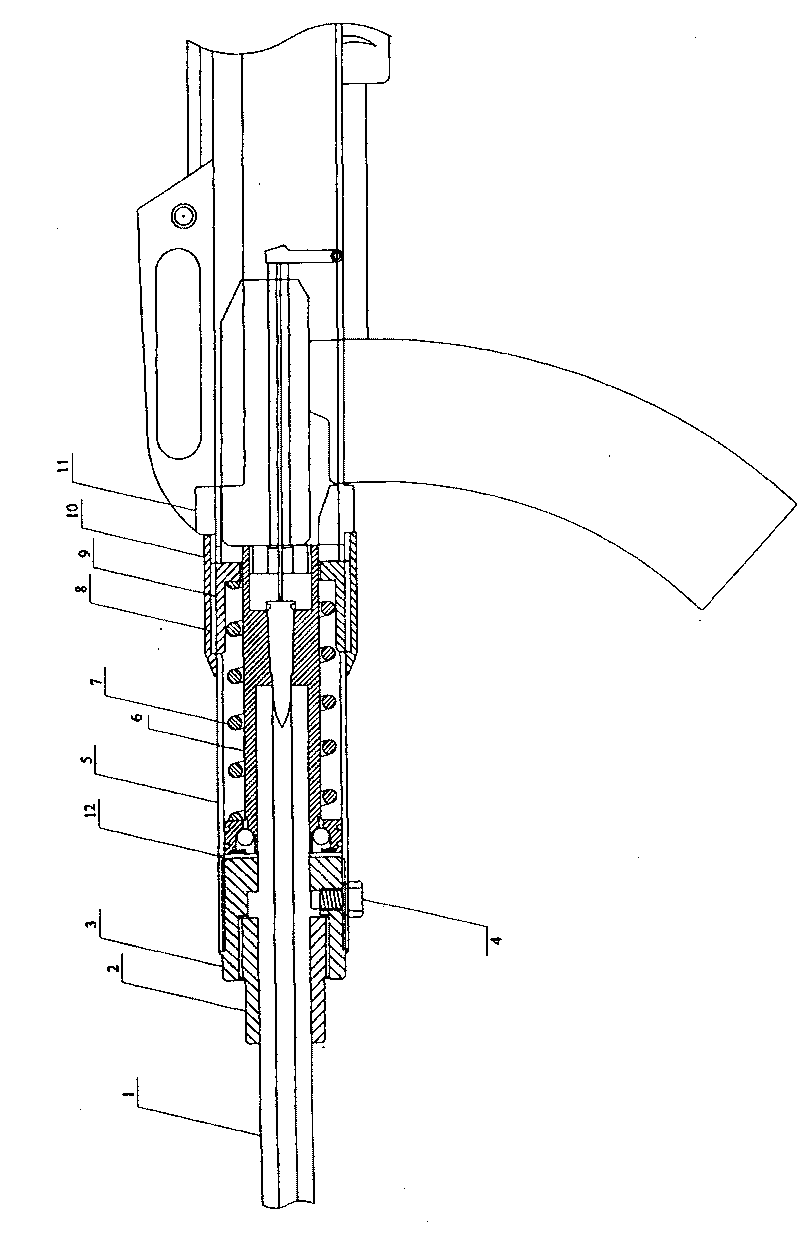

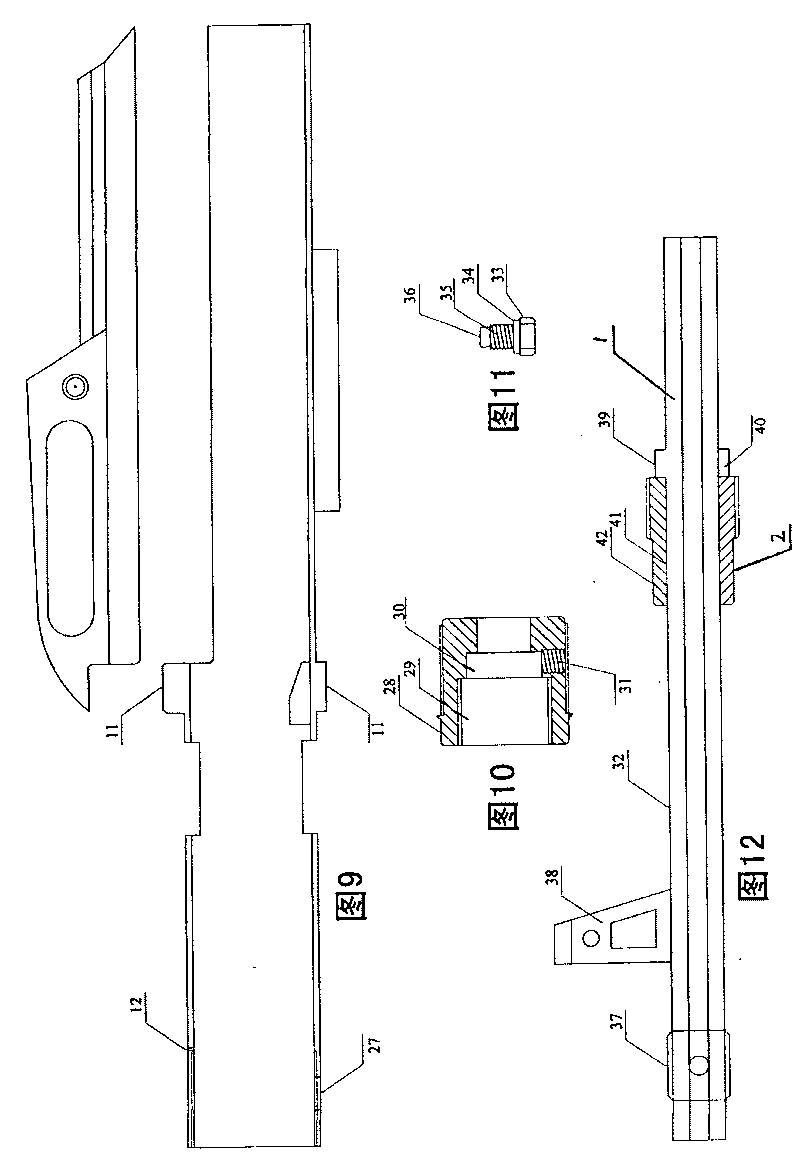

[0035] The present invention consists of a joint transmission device, an air damping device, a gun barrel replacement device, a casing 5, a magazine, a grip, a gun stock, a sight, a firing machine assembly and a rotary locking bolt assembly, wherein:

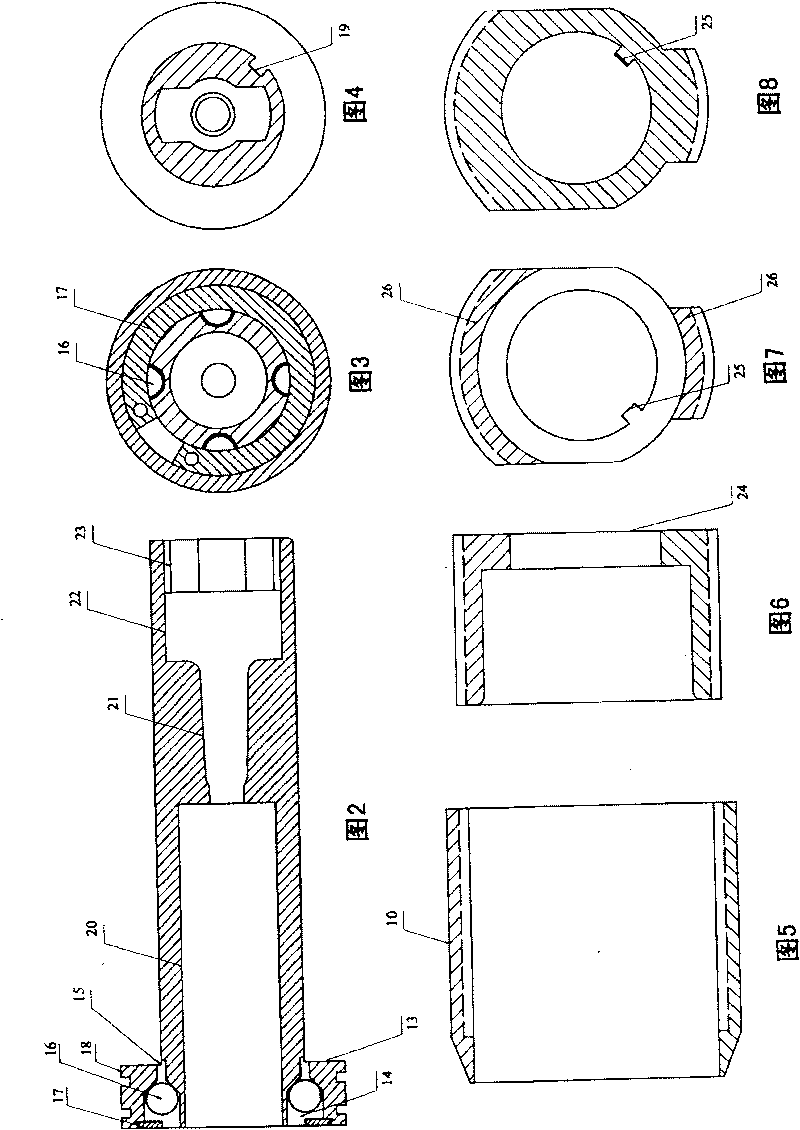

[0036] The joint transmission device is composed of a sliding joint sleeve 6, a buffer spring 7 and an energy adjustment screw pair 8. An outwardly protruding annular air damping piston 13 is processed on the outer left end of the cylindrical sliding joint sleeve 6. The head plane of the air damping piston 13 is uniformly processed with four one-way air valves 14. The one-way air valve 14 is composed of a funnel-shaped air passage 15, a steel ball valve 16 and a "C"-shaped retaining ring 17. The side wall of the shock piston 13 is processed with a piston ring 18, and a slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com