Shock absorption wall and construction method thereof

A technology for walls and corners, applied in the field of shock-absorbing walls and their construction, can solve the problems of large foundation reaction force, hindering building separation, large economic investment, etc., and achieve the effect of reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

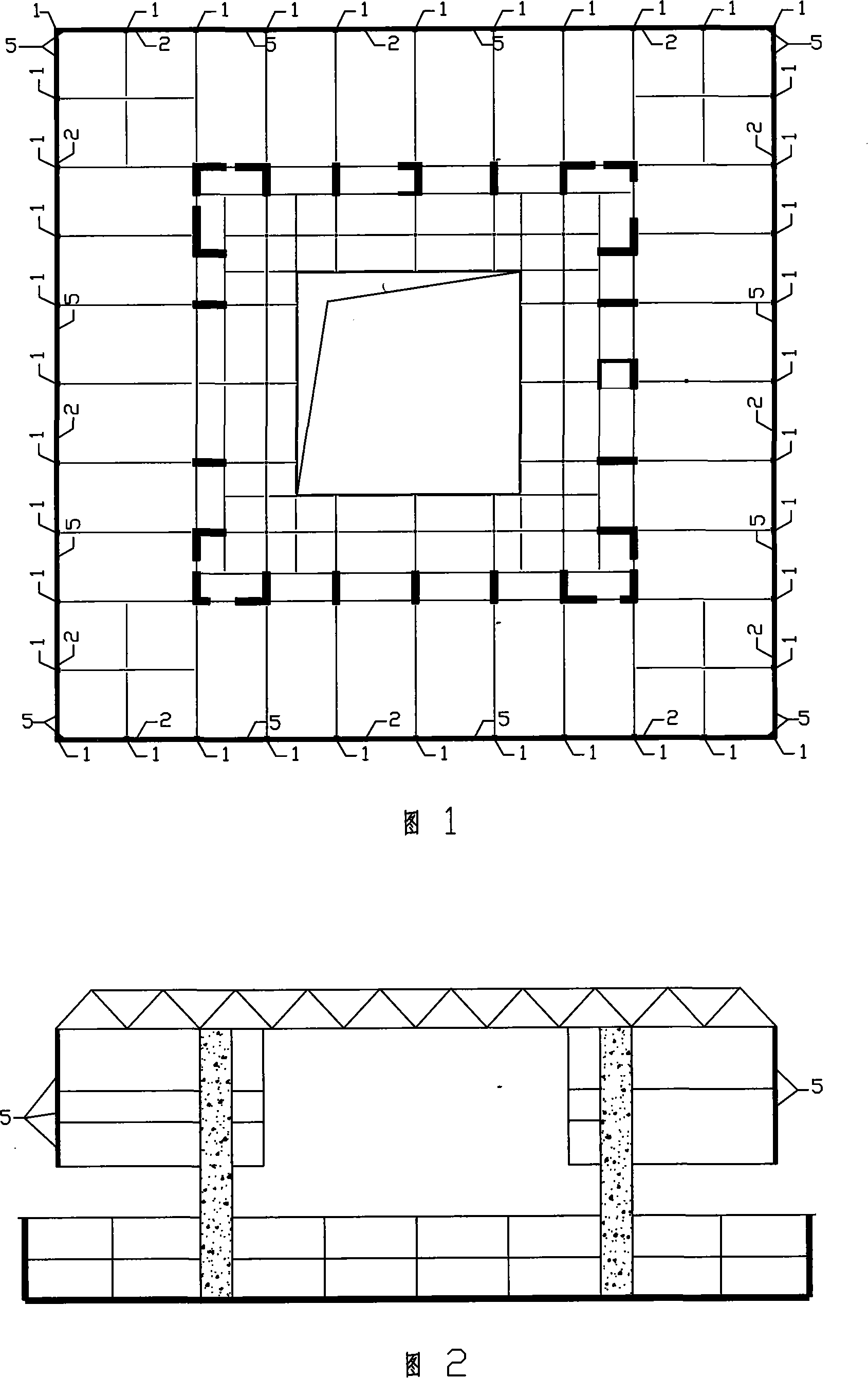

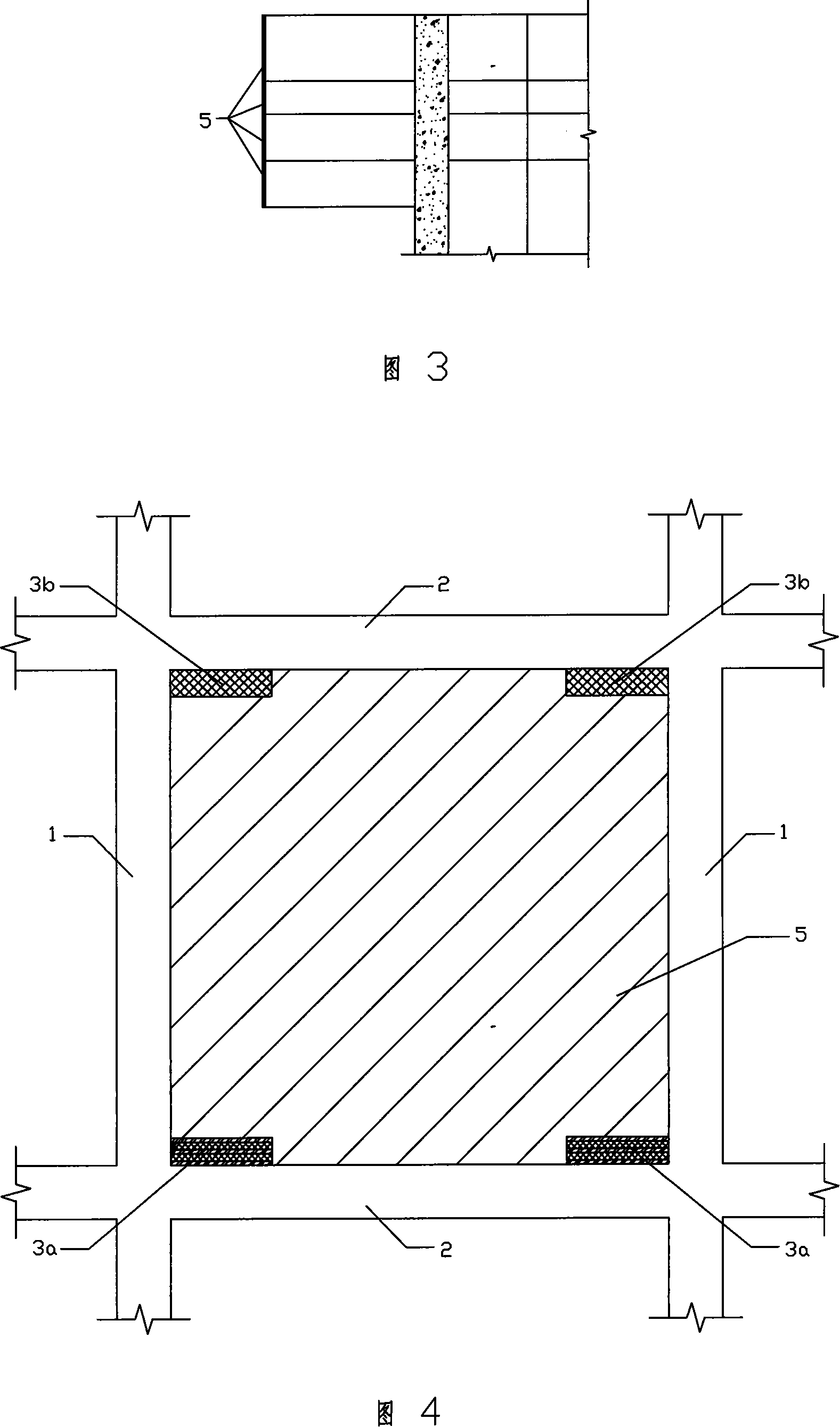

[0068] A kind of shock-absorbing wall as shown in Fig. 1~9, this shock-absorbing wall can be used in the large cantilever building structure or in the suspended space structure, this shock-absorbing wall comprises wall body 5, wall body frame and shock-absorbing device, shock-absorbing The vibration device is a pair of rubber pads arranged symmetrically around the center surface of the wall body. The rubber pads are block-shaped and set at the corners of the wall body 5. The walls 5 are surrounded by structural beams formed by pouring concrete. 15, 22, the structural beam constitutes the peripheral frame of the wall, the rubber pad is in contact with the structural beam of the wall 5, and the rubber pad includes a pair of horizontal rubber pads 3a symmetrically arranged at the lower corner and symmetrically arranged on the upper A pair of horizontal rubber pads 3b at the corner, among which a pair of horizontal rubber pads 3a arranged at the lower corner are interlayer rubber p...

Embodiment 2

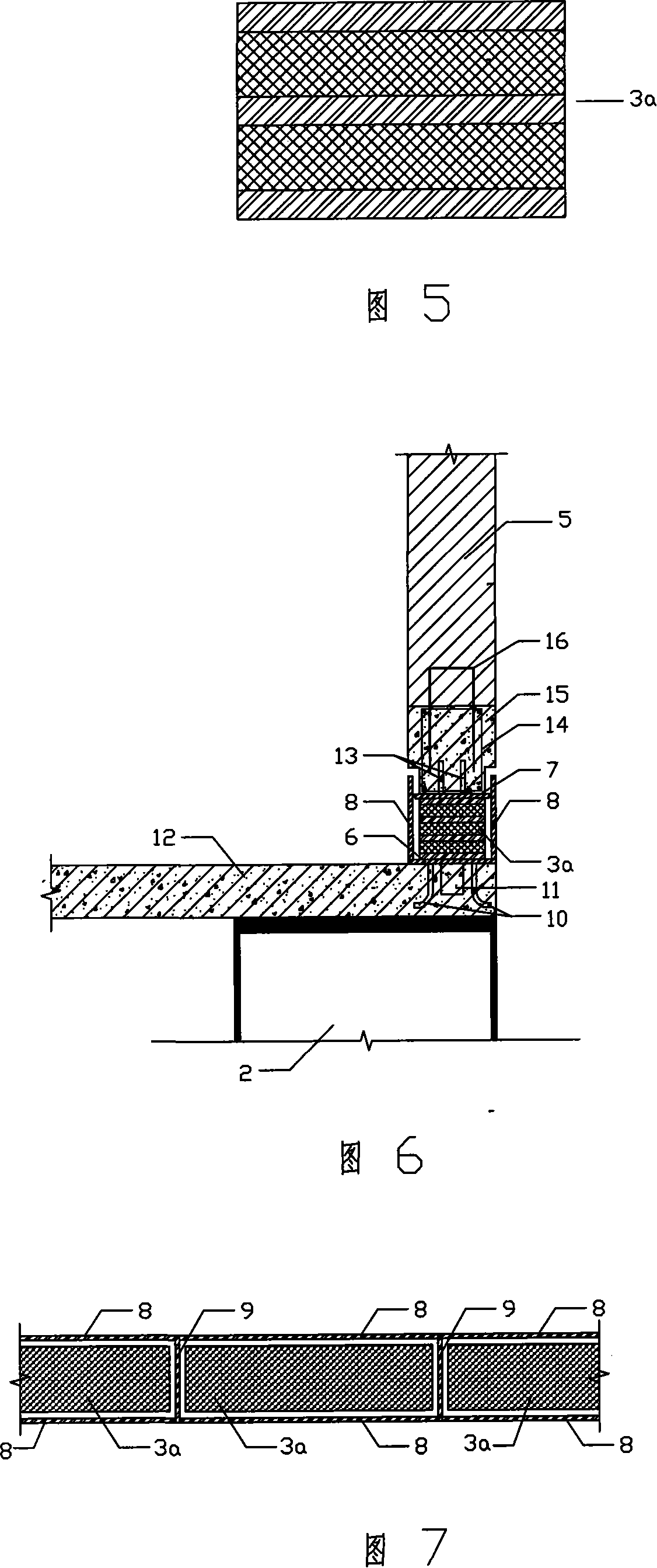

[0080] Different from Embodiment 1, the rubber pad of this embodiment also includes a pair of vertical rubber pads 4a symmetrically arranged at the upper corner and a pair of vertical rubber pads 4b symmetrically arranged at the lower corner. It is a clean rubber pad without compression stiffness, as shown in Figures 10-12, the vertical rubber pads 4a, 4b and the horizontal rubber pads 3a, 3b are perpendicular to each other to form a right-angled structure, and the vertical rubber pads The pad also has the same peripheral device as the horizontal rubber pad arranged at the upper corner in Embodiment 1, and the peripheral device consists of an outer steel plate 17, an inner steel plate 18 and a middle partition 19 between the outer steel plate and the inner steel plate. Form a plurality of compartments for accommodating vertical rubber pads 4a, 4b, the horizontal planes of the vertical rubber pads 4a, 4b are respectively parallel to the inner and outer steel plates and the middl...

Embodiment 3

[0085] A kind of shock-absorbing wall as shown in Fig. 13~16, this shock-absorbing wall can be used in the large-span building structure, the shock-absorbing device in this shock-absorbing wall is all the same as the shock-absorbing device in embodiment one, and embodiment One difference is that the beam of the wall frame is a frame beam 24, the column of the wall frame is a structural column 23, and the structural column 23 and the frame beam 24 are all reinforced concrete structures, and the remaining structural members and structures The connection relationship between the components is the same as the structure in Embodiment 1, and will not be repeated here.

[0086] When the shock-absorbing wall of the present invention is used in a large-span structure, if the wall frame adopts a steel structure, its construction method is the same as that of the above-mentioned shock-absorbing wall for a large cantilever. For reinforced concrete structures, the construction method adopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com