Method for increasing EVA/PE blending foaming material performance by ozone oxidization

A technology of ozone oxidation and foaming materials, applied in household components, applications, household appliances, etc., can solve the problems of difficult to change the high regularity of PE macromolecular chains, the modification effect is not obvious, and the environment causes pollution, etc., to improve both Phase compatibility, comprehensive performance improvement, low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

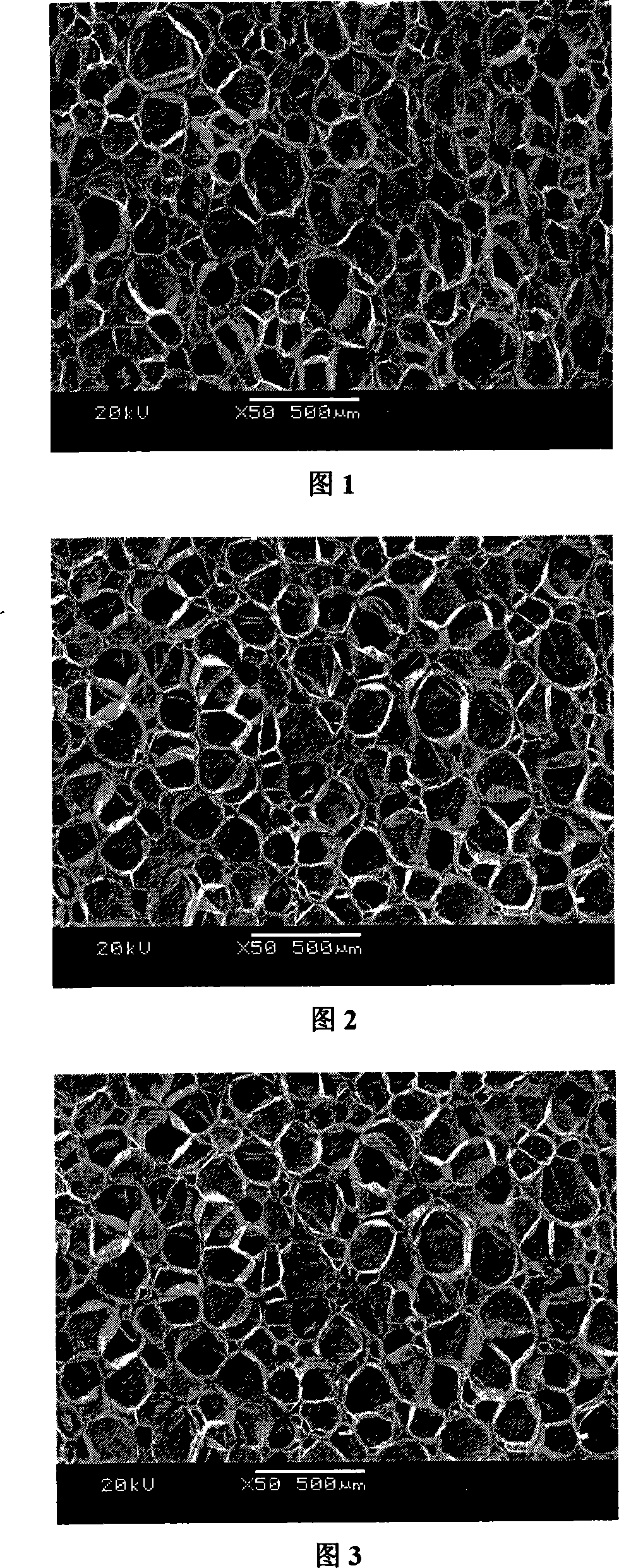

Embodiment 1

[0024] Example 1: Put LDPE into an ozone reactor and react for 40 minutes at a reaction temperature of 80°C and an ozone concentration of 55 mg / L to obtain o-LDPE. 30 g of o-LDPE, 70 g of EVA, 0.65 g of DCP, and AC blowing agent 3.2g, 0.8 parts of ZnO, 0.4g of HSt and 0.4g of ZnSt were added to the double-roller mixer for melting and mixing. The mixing temperature was 105-130°C, and the tablets were produced after mixing for 10-15 minutes. The obtained EVA / PE The mixed compound is placed in a flat vulcanizer for molding and foaming. The foaming temperature is 160-170 ° C, the molding pressure is 10-15 MPa, and the molding and foaming time is 15-35 minutes to obtain an EVA / PE blended foam material.

Embodiment 2

[0025] Example 2: Put LDPE into an ozone reactor and react for 40 minutes at a reaction temperature of 80°C and an ozone concentration of 55 mg / L to obtain o-LDPE. 15 g of o-LDPE, 85 g of EVA, 0.65 g of DCP, and AC blowing agent 3.2g, 0.8 parts of ZnO, 0.4g of HSt and 0.4g of ZnSt were added to the double-roller mixer for melting and mixing. The mixing temperature was 105-130°C, and the tablets were produced after mixing for 10-15 minutes. The obtained EVA / PE The mixed compound is placed in a flat vulcanizer for molding and foaming. The foaming temperature is 160-170 ° C, the molding pressure is 10-15 MPa, and the molding and foaming time is 15-35 minutes to obtain an EVA / PE blended foam material.

Embodiment 3

[0026] Example 3: Put LDPE into an ozone reactor and react for 60 minutes at a reaction temperature of 80°C and an ozone concentration of 55 mg / L to obtain o-LDPE. 30 g of o-LDPE, 70 g of EVA, 0.65 g of DCP, and AC blowing agent 3.2g, 0.8 parts of ZnO, 0.4g of HSt and 0.4g of ZnSt were added to the double-roller mixer for melting and mixing. The mixing temperature was 105-130°C, and the tablets were produced after mixing for 10-15 minutes. The obtained EVA / PE The mixed compound is placed in a flat vulcanizer for molding and foaming. The foaming temperature is 160-170 ° C, the molding pressure is 10-15 MPa, and the molding and foaming time is 15-35 minutes to obtain an EVA / PE blended foam material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com