Anti-skid sleeve with even thickness bucket wall

A non-slip sleeve and cylinder wall technology, applied in the direction of manufacturing tools, wrenches, screwdrivers, etc., can solve the problem of not being able to provide a stable holding effect, and achieve the effect of saving materials, reducing weight, and preventing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

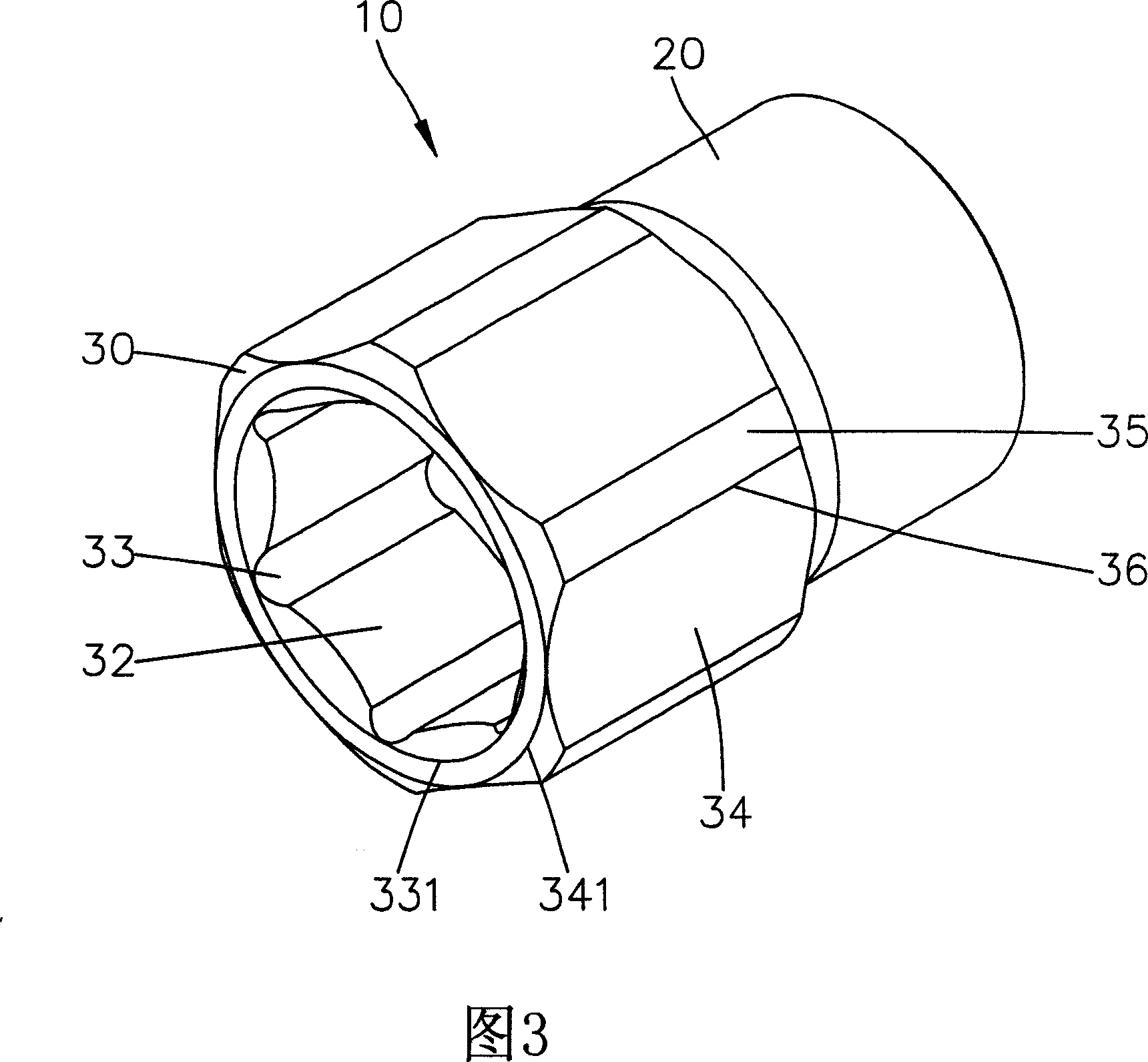

[0034] 3 and 4, the anti-slip sleeve 10 of the present invention includes a plug end 20 and a pull end 30; wherein:

[0035] The insertion end 20 is used for assembly of driving tools such as a ratchet wrench, and the insertion end 20 is provided with a square socket 21 of a predetermined size for insertion and connection of the drive head of the ratchet wrench.

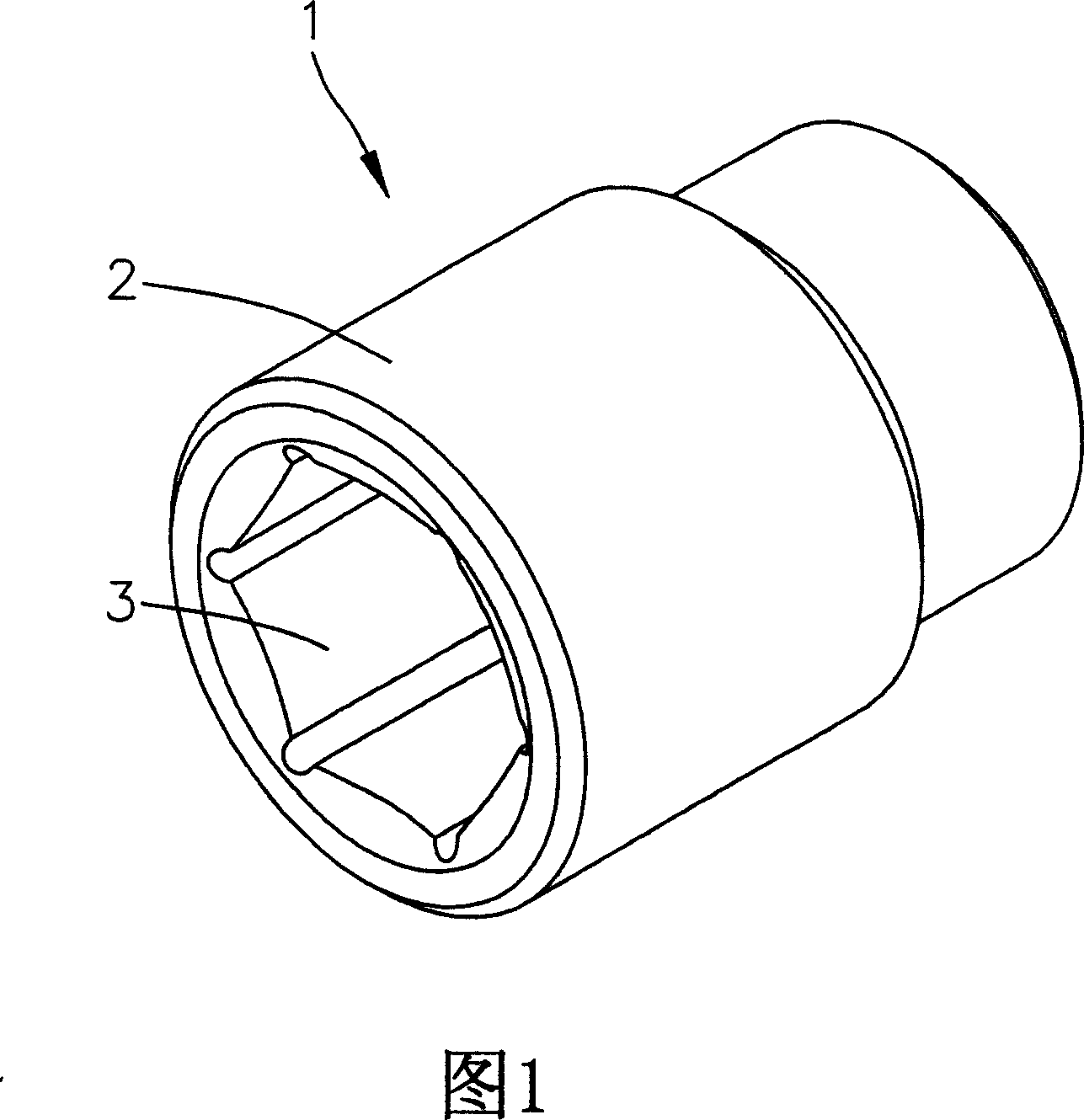

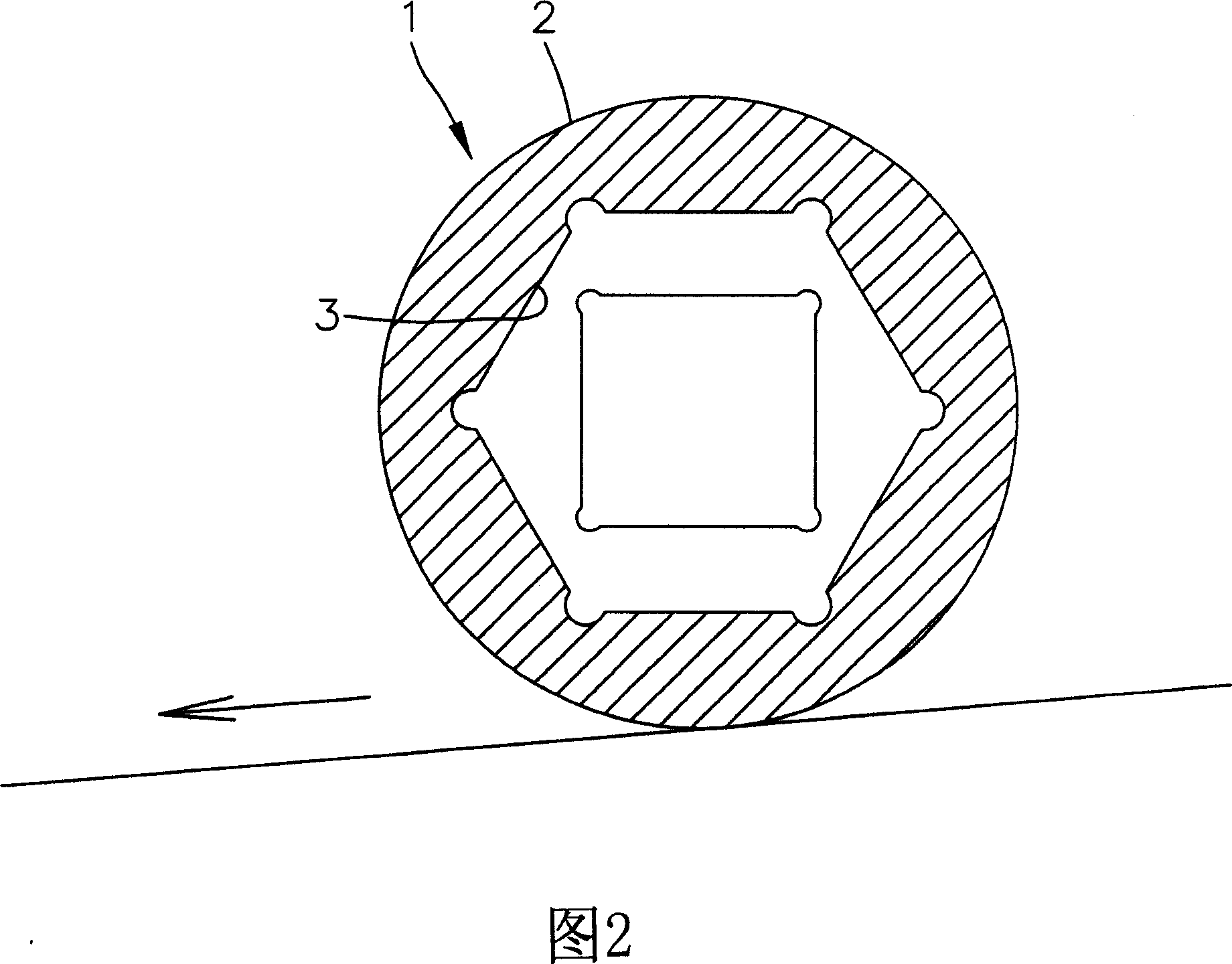

[0036] The wrenching end 30 is located at the end of the non-slip sleeve 10 opposite to the insertion end 20. The wrenching end 30 has a hexagonal cylinder wall 31, and the inner side of the cylinder wall 31 is provided with six A planar pulling part 32, said pulling part 32 can contact working objects such as hexagonal bolt heads or nuts to perform turning work, because the pulling part 32 is set as a planar shape, so it can be used with the work Objects produce a larger area of contact, and can obtain a high-efficiency transmission effect of turning force. Each end corner of the inner side of the cylinder wall 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com