A circular groove powder precision spreading device

A circular trough and precision technology, applied in the field of circular trough powder precision spreading device, can solve the problems of low production efficiency, slow material spreading, and reduce the service life of molds, and achieve stable mechanical properties, uniform internal density, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

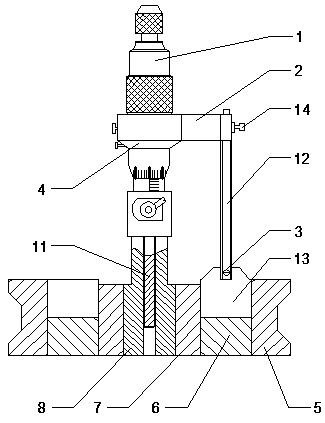

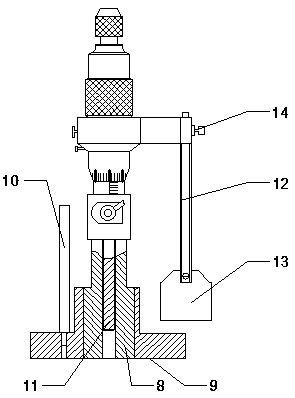

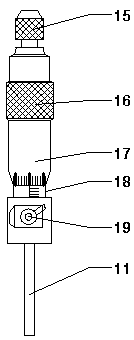

Embodiment 1

[0020] Embodiment 1: as Figure 1-2 As shown, the present invention provides a circular groove powder precision spreading device, which mainly includes a micrometer 1, a rotating arm 2, a spreading rod 3, a supporting ring 4, a circular groove mold, and a shaft core 8; the micrometer 1 There is a rotating arm 2 and a supporting ring 4 on it, the supporting ring 4 is located under the rotating arm 2, one end of the rotating arm 2 is sleeved on the movable scale ring 17 of the micrometer 1, and the other end of the rotating arm 2 is provided with a push The material rod 3 and the two ends of the rotating arm 2 are provided with stop knobs II14. Described spreader bar 3 is made up of blade bar 12 and blade 13; One end of leaf bar 12 is installed on the rotating arm 2, and the other end of leaf bar 12 is equipped with blade 13, and blade 13 cooperates with circular groove mould. The supporting ring 4 is a tapered ring, and the tapered ring is matched with the micrometer 1 . The ...

Embodiment 2

[0024] Embodiment 2: A circular groove powder precision spreading device, the circular groove mold is a part, and a circular groove is opened on the mold.

[0025] Other structures are the same as in Embodiment 1.

Embodiment 3

[0026] Embodiment 3: A circular groove powder precision spreading device, the micrometer is refitted from a spiral micrometer without the frame, and the spiral micrometer is available in the market.

[0027] Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com