A method and building suitable for underground layer addition of frame structure buildings

A frame structure and building technology, applied in building construction, construction, building maintenance, etc., can solve the problems of large plane space, waste of underground space, occupation, etc., and achieve the effect of reducing occupation and waste, and achieving significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

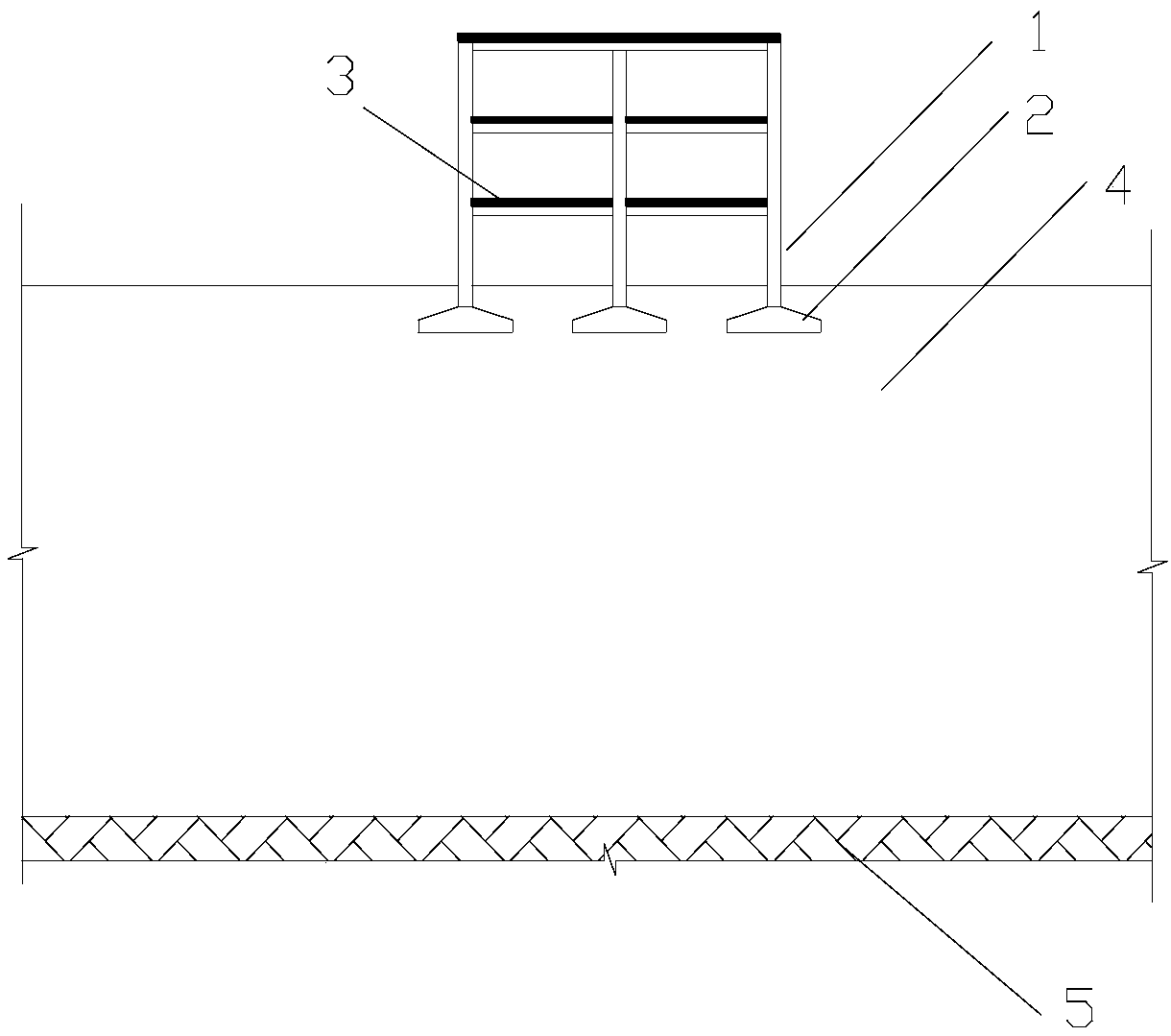

[0049] Embodiment 1: a kind of method that is applicable to the underground building of frame structure building, is suitable for such as figure 1 and figure 2 The frame structure building shown has a frame column 1 , an independent foundation 2 and a structural beam slab 3 , and a part of the frame column 1 and the independent foundation 2 are located in the surface foundation soil 4 .

[0050] Carrying out the underground layer-adding method for the concrete building of this frame structure mainly comprises the following steps:

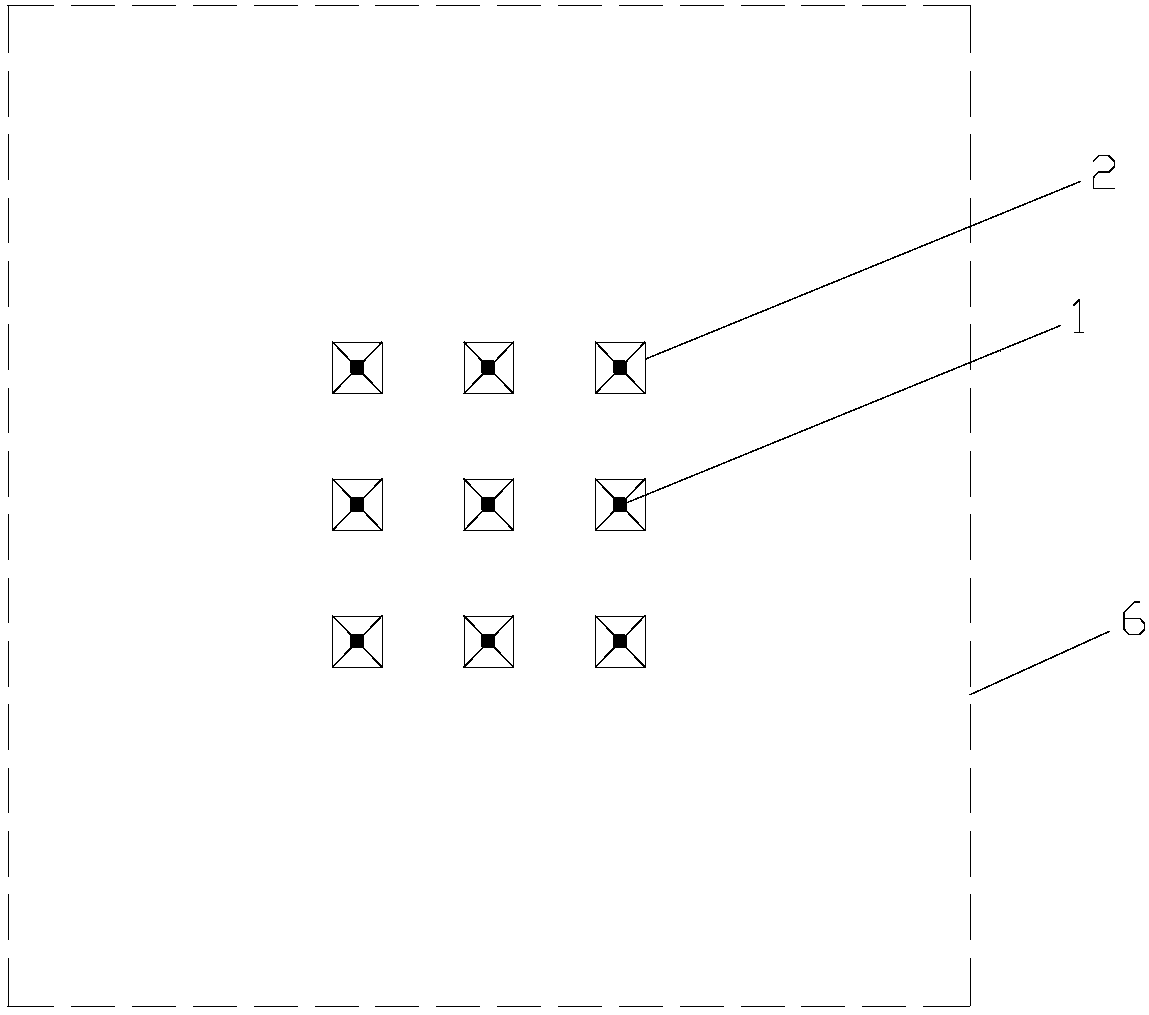

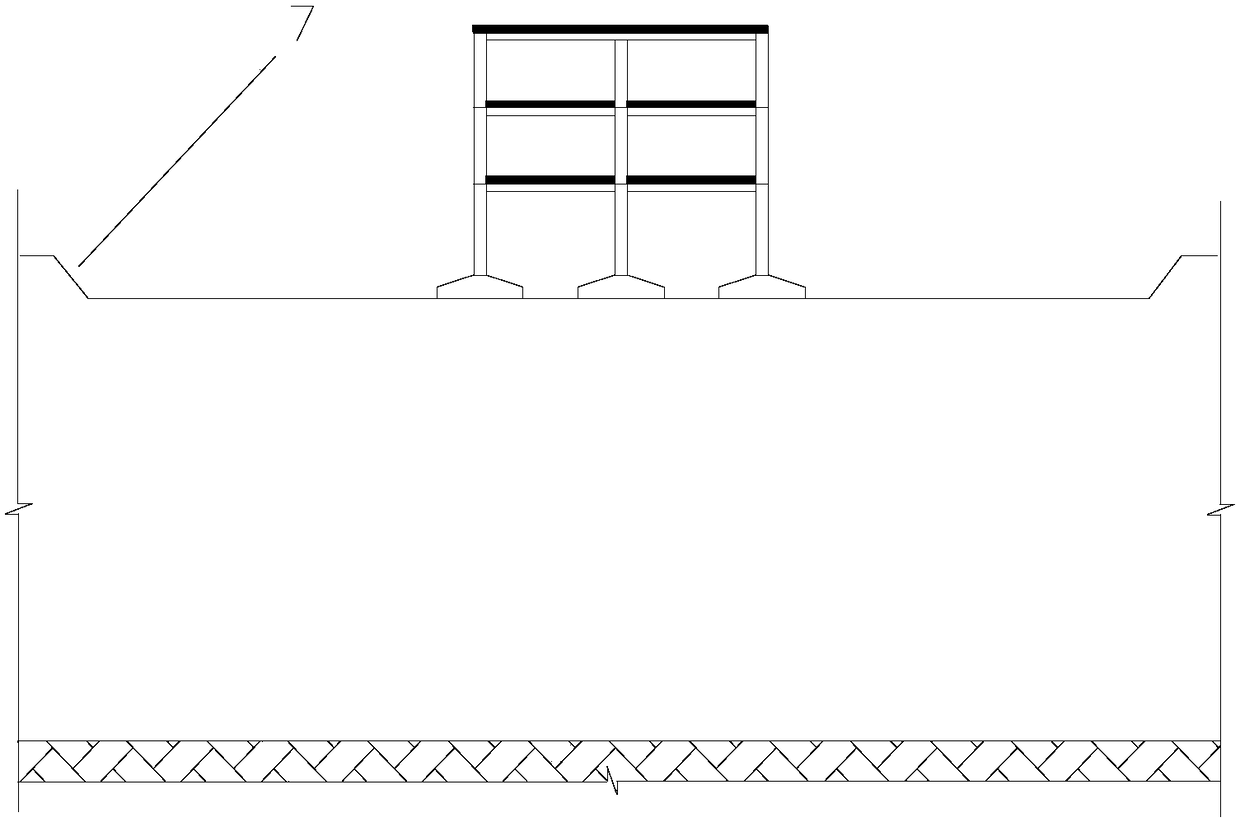

[0051] refer to image 3 and Figure 4 As shown, excavate the surface layer foundation soil 4 above the independent foundation 2 of the building, the boundary is the sideline 6 of the underground garage, and the horizontal and vertical independent foundation 2 below the frame column 1 of the building are all exposed. For the surface foundation soil 4 in the underground garage area, the foundation pit side slope 7 formed during the excavation pro...

Embodiment 2

[0060] Embodiment 2: a kind of building, this building is frame structure, and its structure is as Figure 13 and Figure 14 As shown, the building has a frame column 1, an independent foundation 2 and a structural beam slab 3, and there is a newly added garage below the building;

[0061] Wherein, the newly added garage is constructed by the method described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com