Novel stainless bearing steel and method for manufacturing same

A technology of stainless steel bearings and manufacturing methods, applied in the field of stainless steel, to achieve the effects of excellent mechanical properties, high hardness, and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

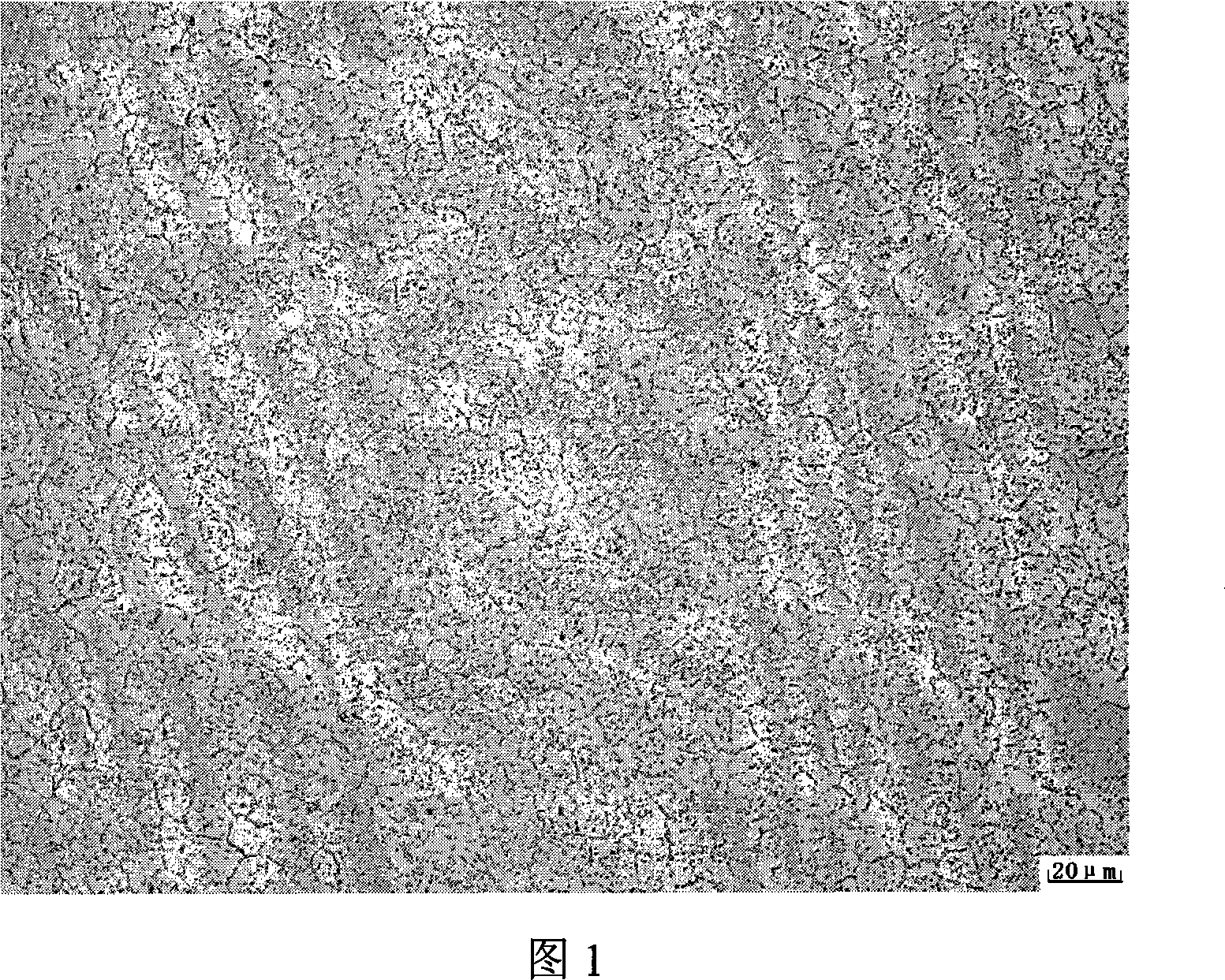

Image

Examples

Embodiment 1

[0034] A new type of stainless bearing steel, the bearing steel contains: C 0.42 (weight percent, the same below), Cr 15.52, Ni 0.78, Mo 1.64, N 0.12, Mn 0.74, Si 0.26, S 0.006, P 0.020, V 0.34, The rest is Fe; the manufacturing method of the bearing steel is as follows: the charge containing the above components is smelted in a non-vacuum induction furnace, electroslag remelted, forged and formed, and then subjected to the following heat treatment process: heat preservation at 1030 ° C for 1 hour, water quenching to room temperature, and then at 180 ° C for 4 hours to obtain stainless bearing steel. The obtained stainless bearing steel is processed into a plunger, installed in a pressure cylinder of medical equipment, and used in a microbial solution for 412 hours. The wear resistance and corrosion resistance of the plunger meet the technical requirements of product design.

[0035] Previously, the plunger used the following materials, which did not work well:

[0036] 1. GC...

Embodiment 2

[0041] A new type of stainless bearing steel, the bearing steel contains: C 0.52, Cr 15.49, Ni 0.29, Mo 1.90, N 0.21, Mn 0.63, Si 0.42, S 0.004, P 0.024, V 0.31, and the rest is Fe; The manufacturing method of the bearing steel is as follows: the charge containing the above components is smelted in a non-vacuum induction furnace, electroslag remelted, forged into a bar, softened and annealed, rough-processed into the inner and outer rings of the bearing, and then subjected to the following heat treatment process: in 1010 Insulate at ℃ for 1 hour, freeze after oil quenching (8 hours at -30 ℃), and then hold at 180 ℃ for 4 hours. The measured hardness is HRC56. The assembled bearings did not appear rusted in the 5% NaCl salt spray test, while the 9Cr18 stainless steel bearings appeared rusted within 24 hours under the same test conditions.

Embodiment 3

[0043] A new type of stainless bearing steel, which contains: C 0.30, Cr 14.00, Ni 1.50, Mo 1.00, N 0.10, Mn 1.00, Si 1.00, S 0.03, P 0.035, Ti 0.50, and the rest is Fe; The manufacturing method of the bearing steel is as follows: the charge containing the above components is smelted in a non-vacuum induction furnace, electroslag remelted, forged and formed, and then subjected to the following heat treatment process: heat preservation at 1050 ° C for 0.5 h, water quenching to room temperature, and then at 150 ° C After heat preservation for 6 hours, a stainless bearing steel was obtained, the measured flexural strength was 3800MPa, and the hardness was HRC55.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com