Evaporator

An evaporator and refrigerant technology, applied in the direction of evaporator/condenser, heat exchanger shell, refrigerator, etc., can solve the problem of reduced heat exchange performance, troublesome assembly of refrigerant flow parts and separated fin parts, and sufficient discharge and other problems to achieve the effect of preventing the reduction of cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

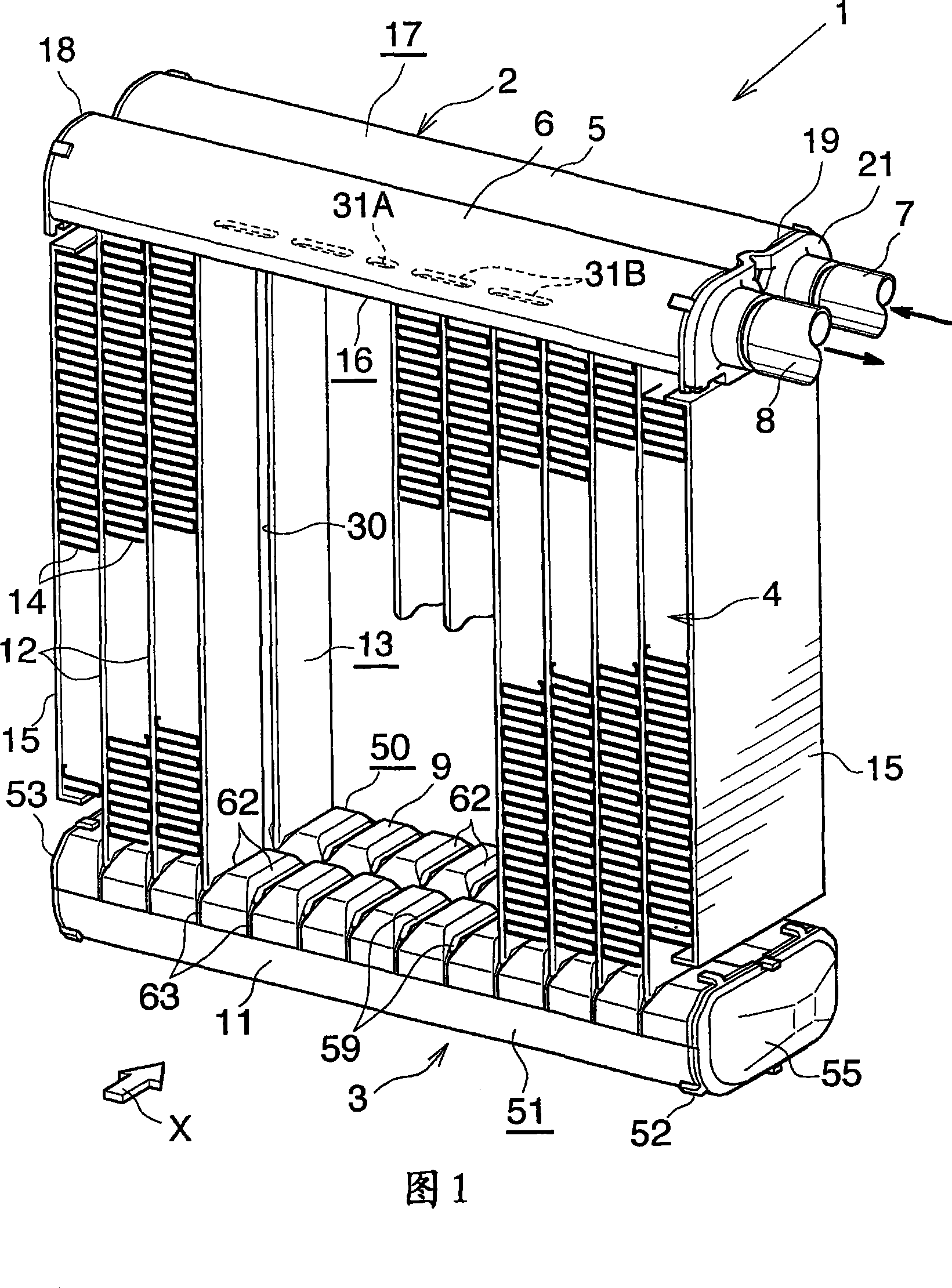

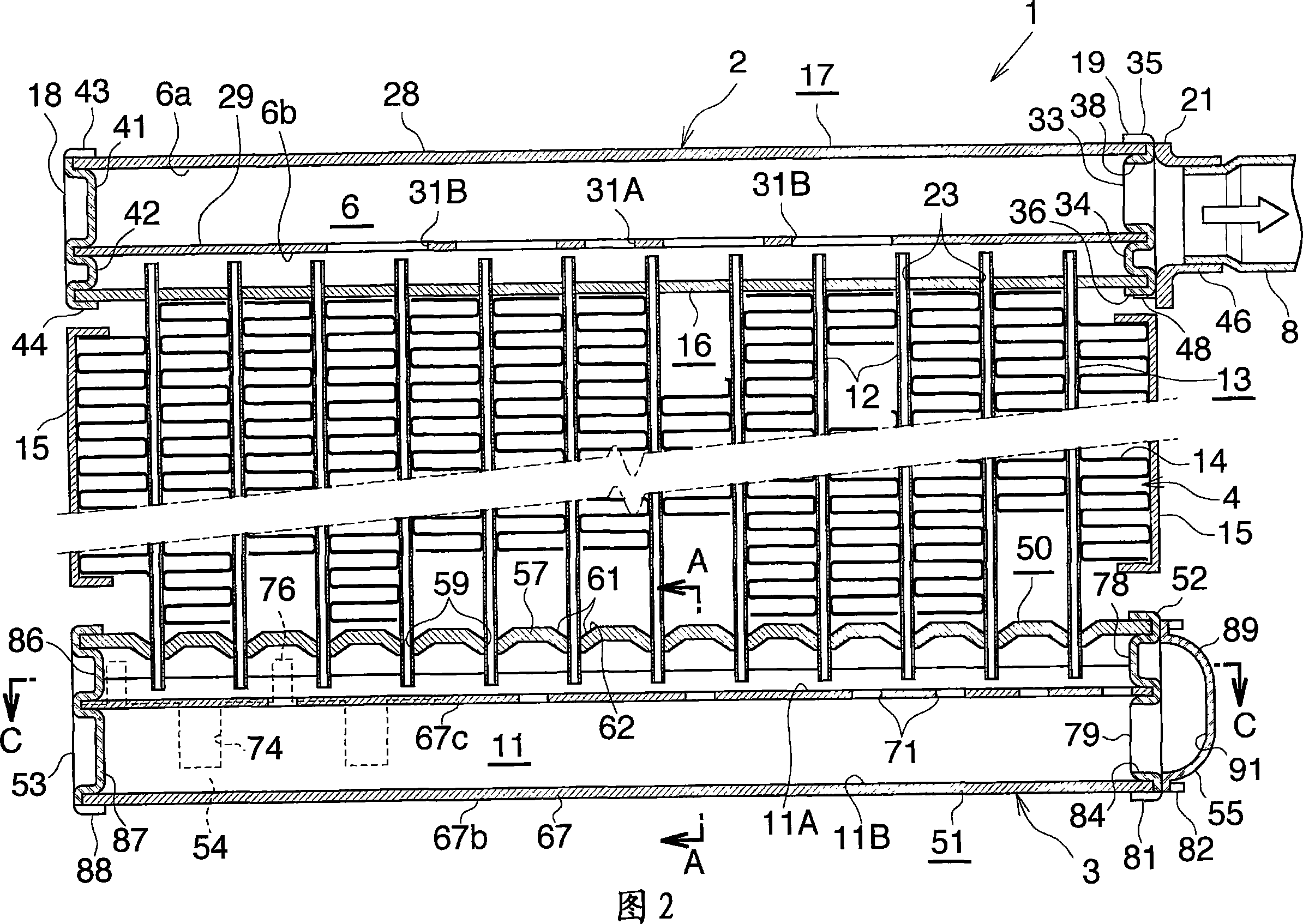

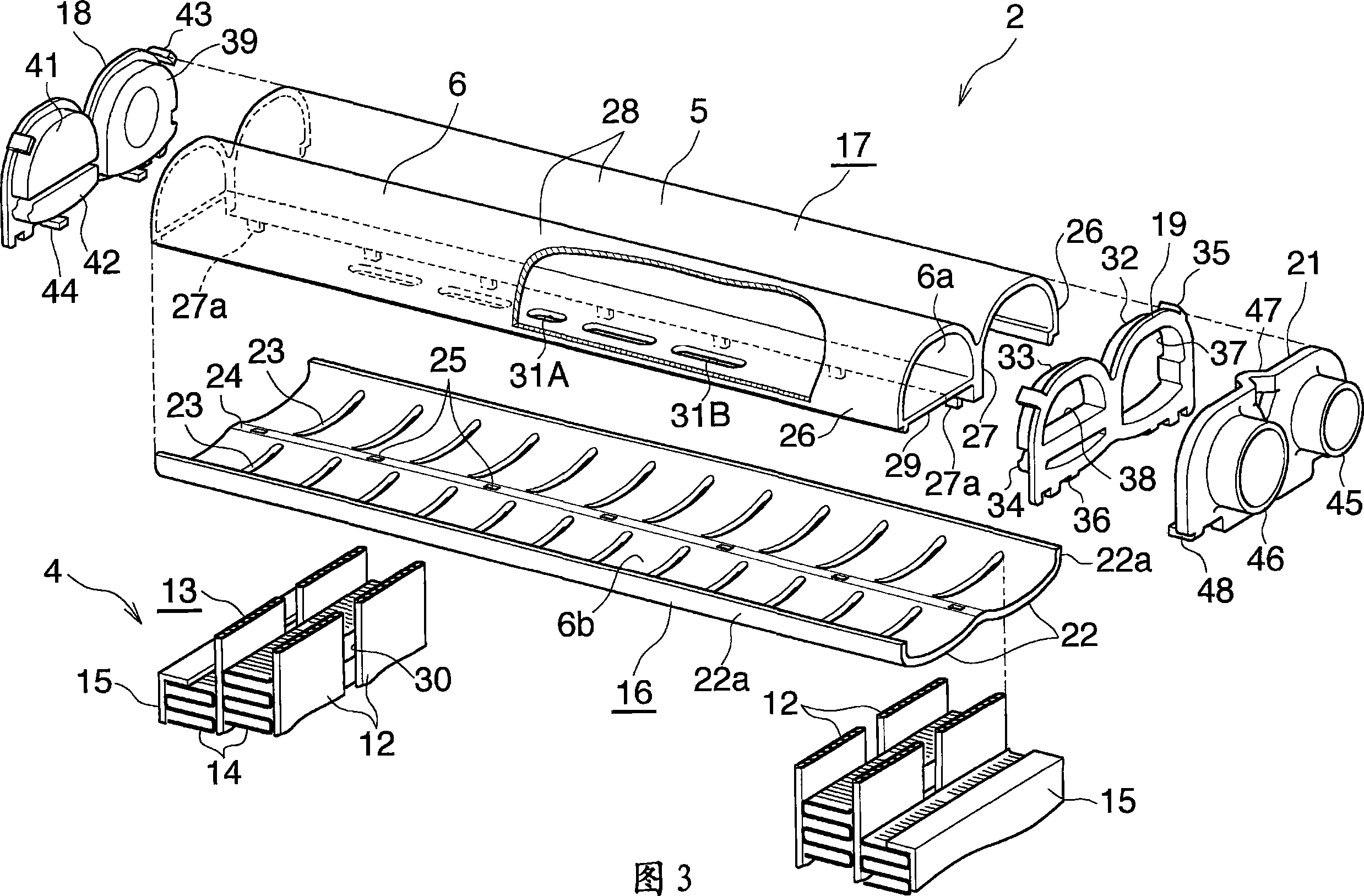

[0049] 1 to 9 show this embodiment.

[0050] 1 and 2 show the overall configuration of the evaporator, and FIGS. 3 to 8 show the configuration of the main part of the evaporator. Figure 9 shows how the refrigerant flows in the evaporator.

[0051] In Figures 1 and 2, an evaporator (1) for a car air-conditioning unit using a chlorofluorocarbon refrigerant includes an aluminum refrigerant inlet-outlet box (2) and an aluminum refrigerant diversion box (3) , the boxes (2) and (3) are vertically separated from each other, and further include a heat exchange core (4) disposed between the boxes (2) and (3).

[0052] The refrigerant inlet-outlet box (2) includes a refrigerant inlet header portion (5) on the side toward the front (downstream side with respect to the direction of airflow) and a side toward the rear (downstream side with respect to the direction of airflow). The refrigerant outlet header (6) on the upstream side). A refrigerant inlet pipe (7) made of aluminum is conne...

Embodiment 2

[0096] This embodiment is shown in Figures 10-13.

[0097] In this embodiment, the evaporator (100) is configured such that a plurality of refrigerant flow parts (101) are stacked and combined in the left and right directions, while their widths extend in the front and rear directions (airflow direction), each of which flows The components each have a rectangular shape elongated in the vertical direction.

[0098] Each refrigerant flow part (101) includes two vertically extending rectangular aluminum plates (102) whose peripheral portions are brazed together. Each aluminum plate (102) is made of aluminum brazing sheet material having a layer of brazing material on each of its opposite sides. Two (front and rear) vertically extending, protruding refrigerant flow tube portions (103) and (104) and a protruding header forming portion (105) are provided between these two aluminum plates (102) and (106), thus partially constituting the refrigerant flow part (101). Protruding head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com