Surface treatment, specification and assembling method for microelectronic element and its storage structure

A technology for microelectronic components and surface treatment, applied in electrical components, circuits, semiconductor/solid-state device manufacturing, etc., to solve the problems of chip corrosion, delamination, product debris, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

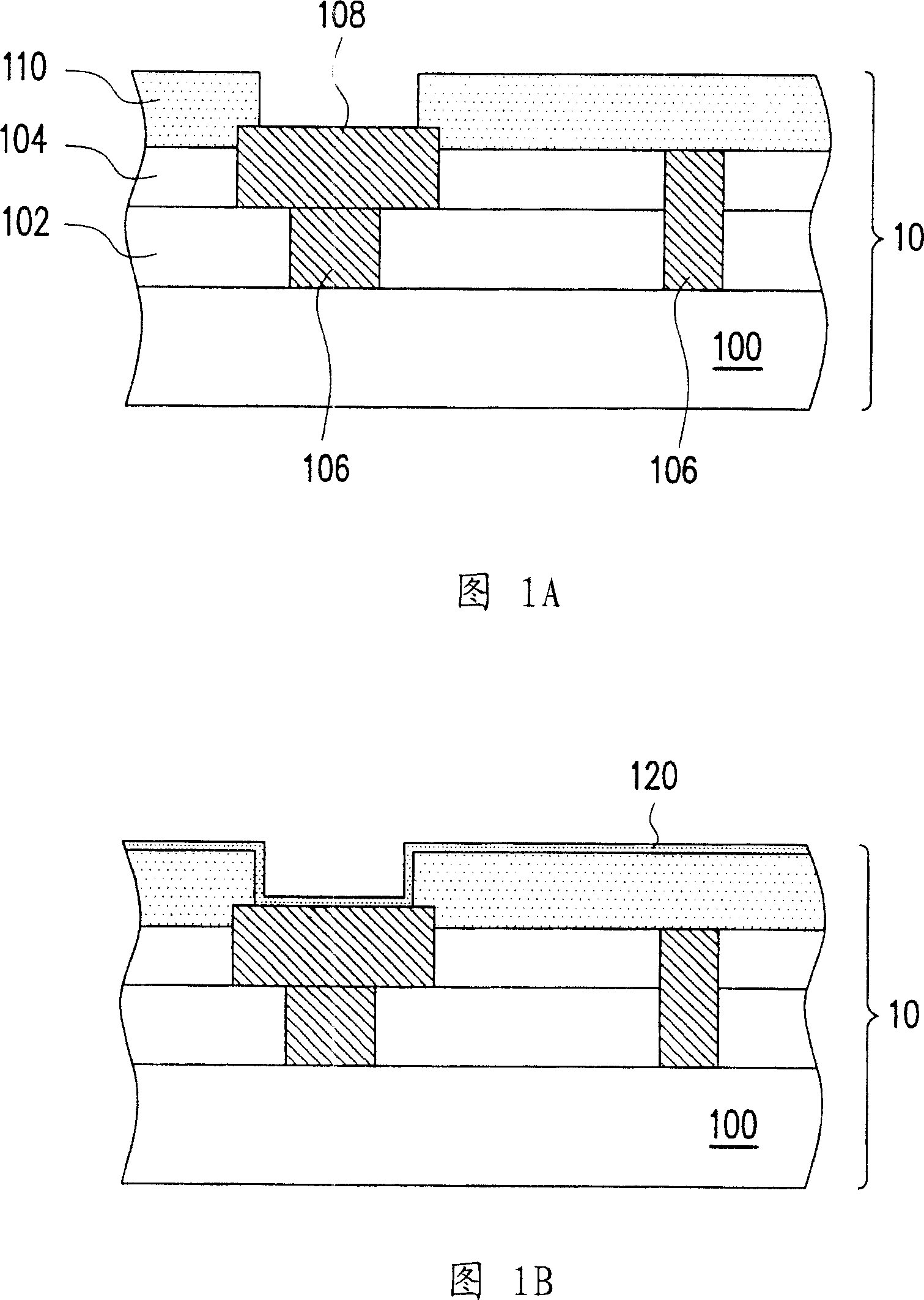

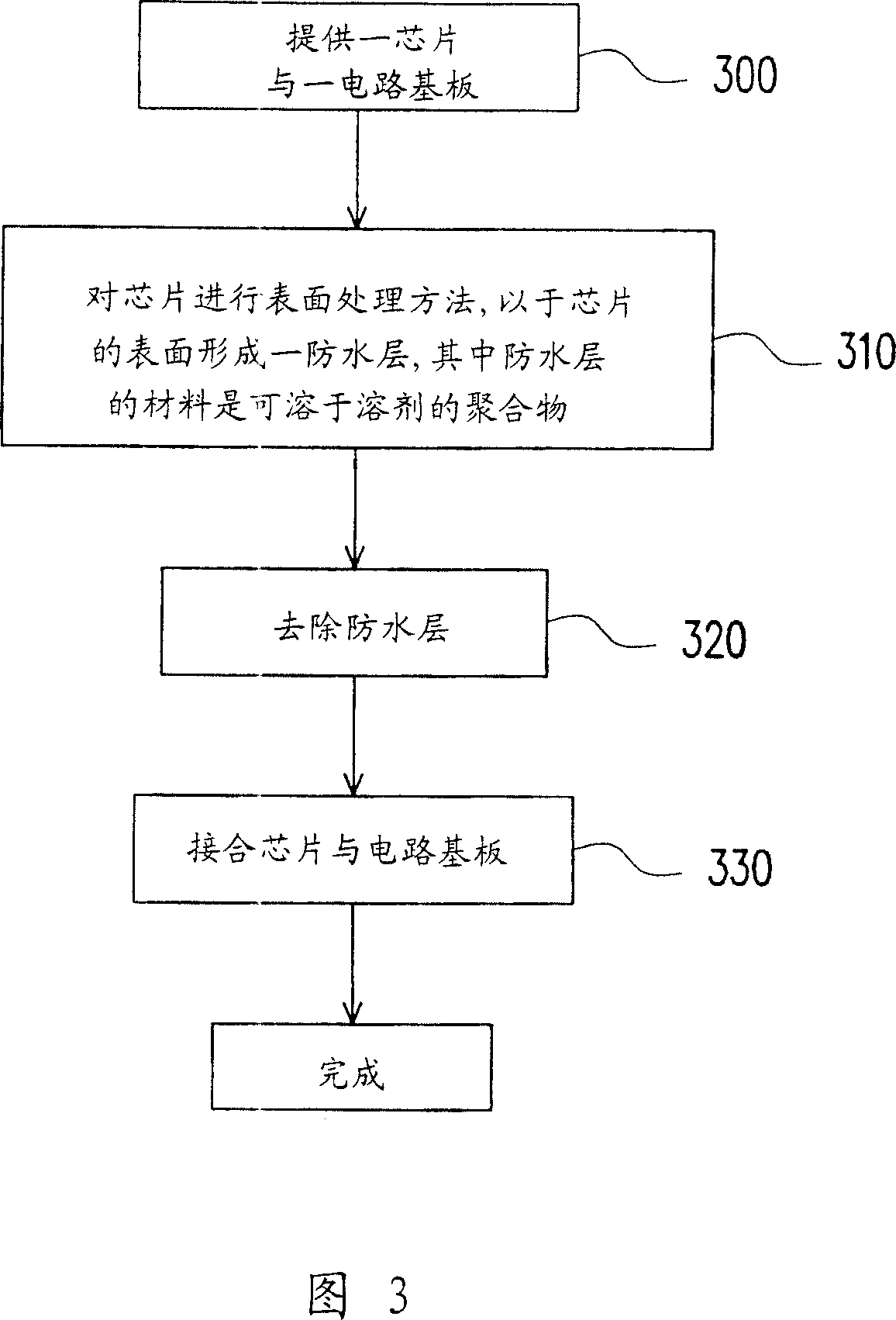

[0034] 1A to 1B are cross-sectional views of a surface treatment process of a microelectronic element according to a first embodiment of the present invention.

[0035] Please refer to FIG. 1A first. The present invention proposes a surface treatment method for microelectronic components, which is suitable for a chip 10 that has completed the back-end process (BEOL), wherein the chip 10 is, for example, composed of a substrate 100, several layers of dielectric layers 102, 104 and 110 , the plug 106 and the pad 108 are formed. The solder pads 108 and the outermost dielectric layer 110 are exposed on the surface of the chip 10 . The above structure of the chip 10 is just an example, and is not intended to limit the scope of application of the present invention.

[0036] Next, please refer to FIG. 1B , the method of this embodiment is to form a layer of solvent-soluble polymer layer (solvent dissolvable polymer layer) 120 on the surface of the chip 10, and its thickness is, for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com