Continuous pavement friction coefficient testing method

A technology of road surface friction coefficient and testing method, which is applied in the field of testing, can solve the problem that the measurement method is not enough to reflect the friction between tires and roads, and achieve the effects of improving testing efficiency and testing speed, convenience and safety factor, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

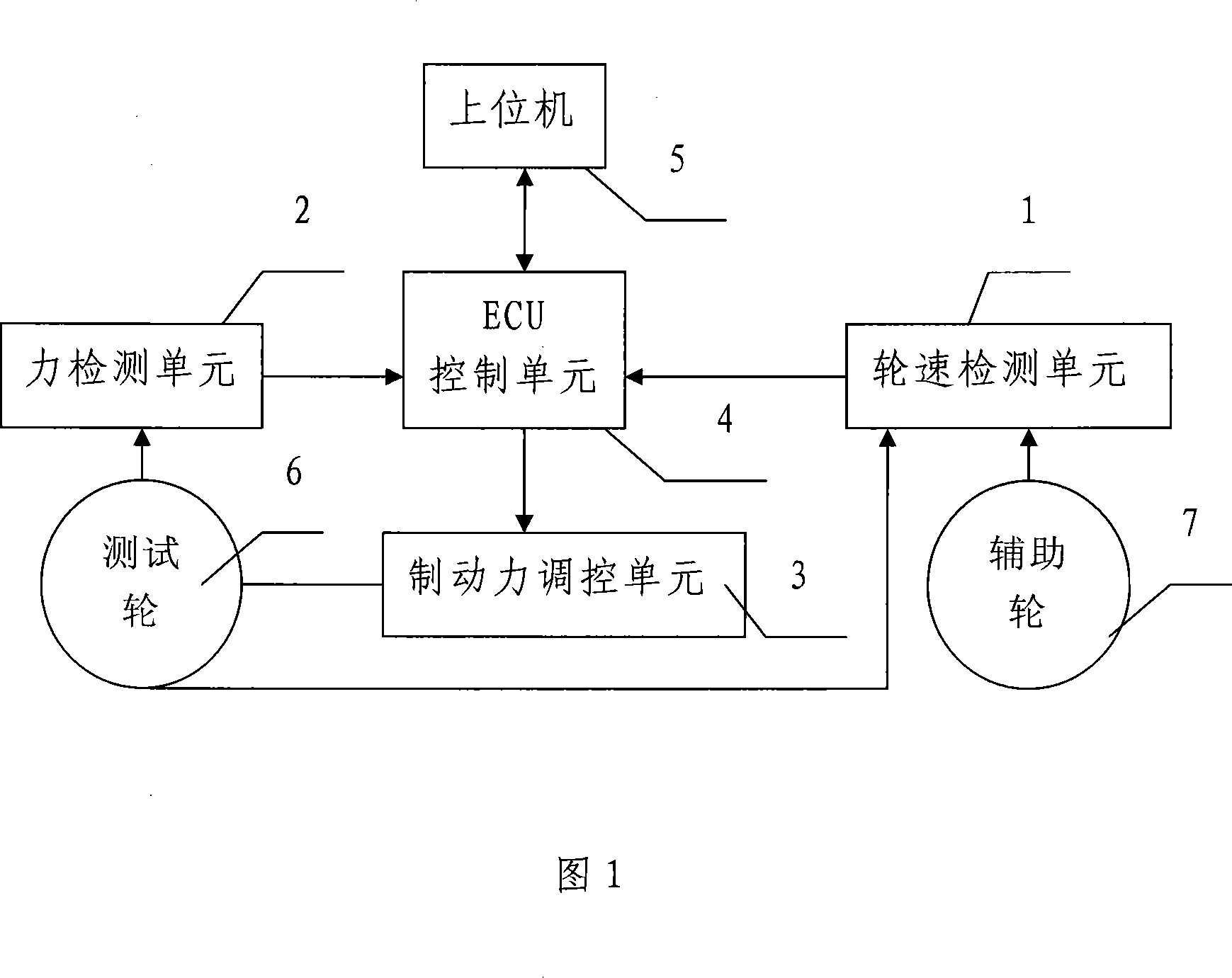

[0027] As shown in Figure 1, the continuous friction coefficient test device is composed of five parts: wheel speed detection unit 1, force detection unit 2, braking force control unit 3, ECU control unit 4 and host computer 5.

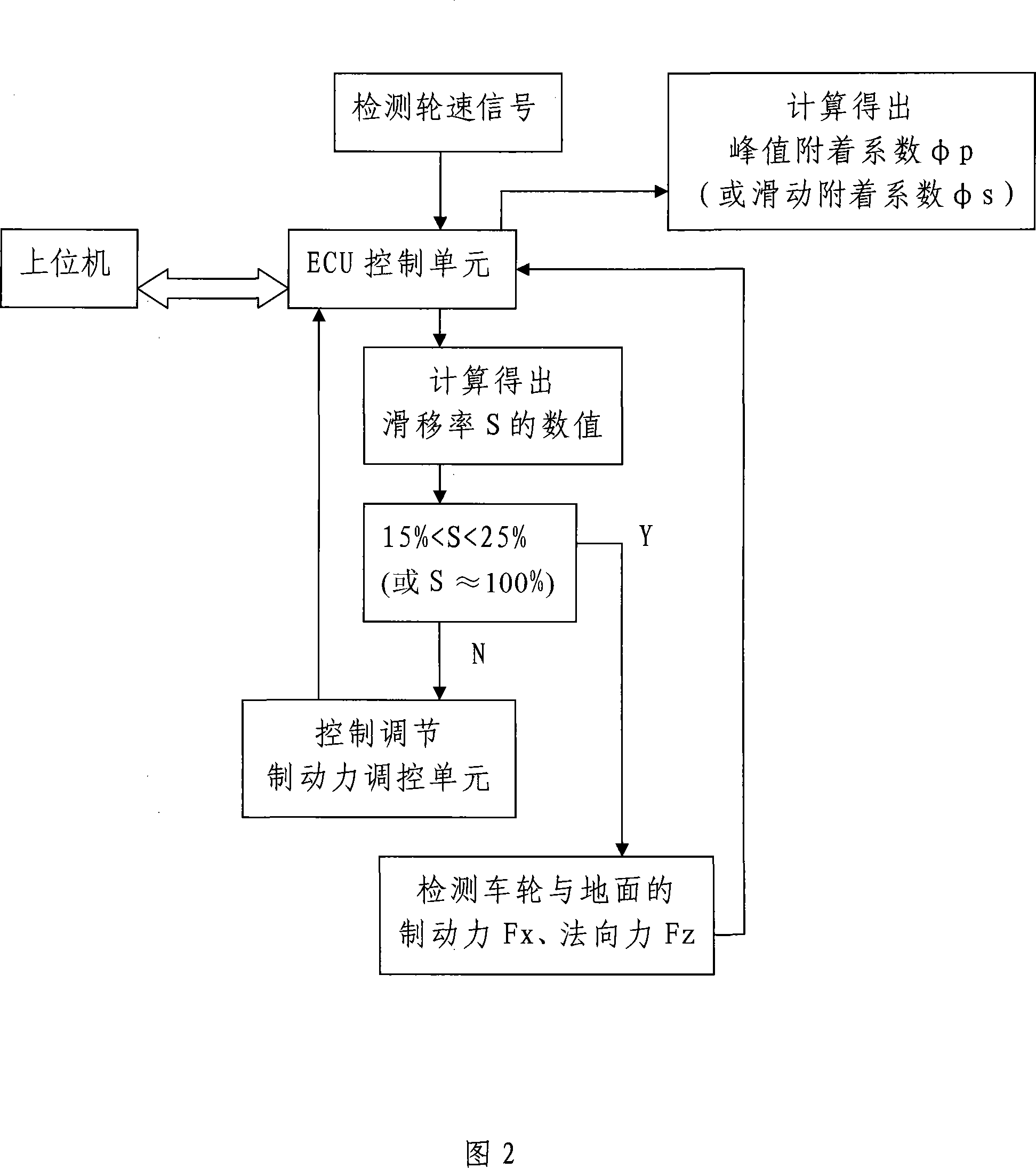

[0028] As shown in Figure 2, described continuous road surface friction coefficient testing method comprises the steps:

[0029] The first step is to detect the wheel speed signal and obtain the slip rate S of the wheel: the two wheel speed signals of the test wheel 6 and the auxiliary wheel 7 obtained by the detection of the wheel speed sensor are transmitted to the ECU control unit 4, and the slip ratio of the wheel is calculated. Mobility S.

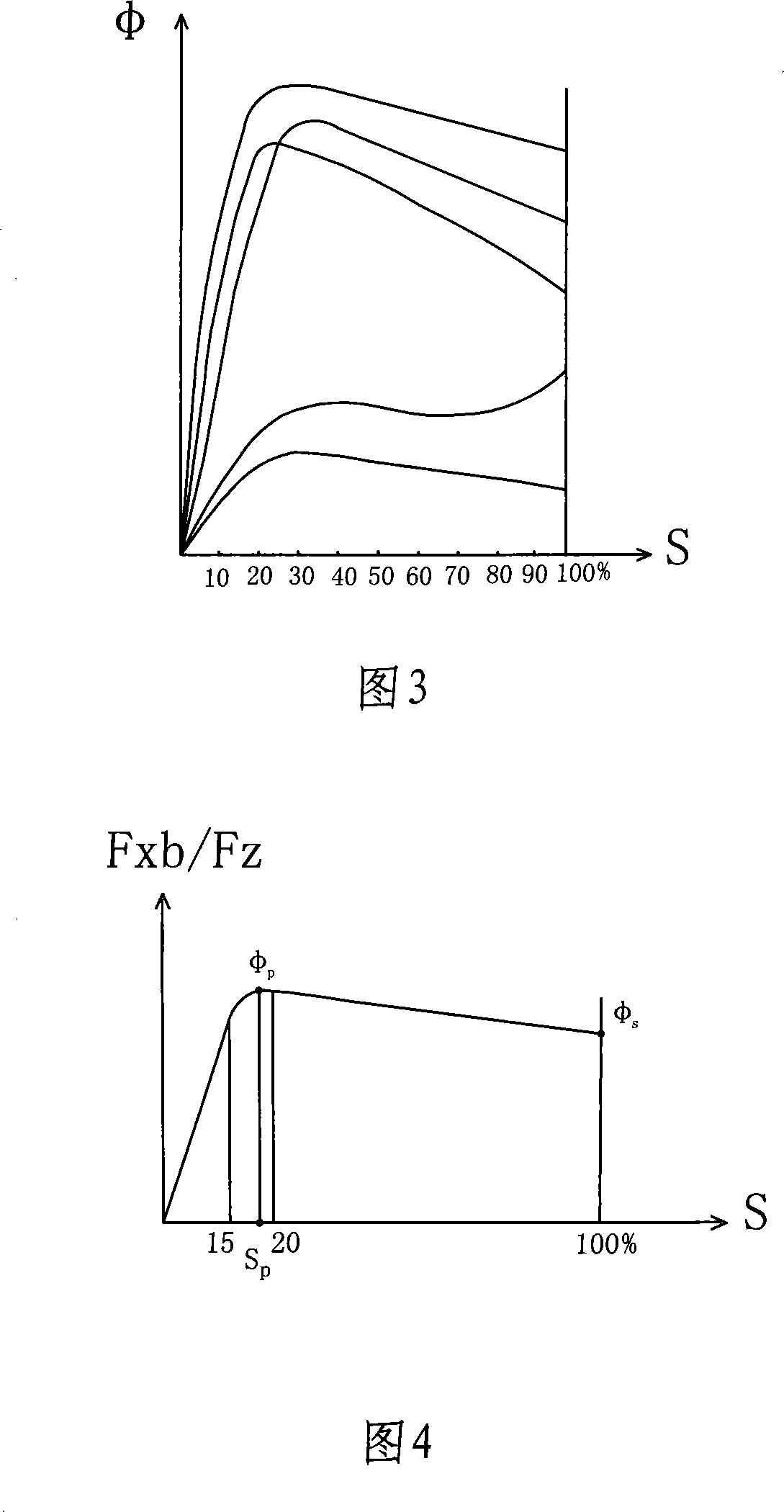

[0030] According to the research results of automobile dynamics and tire mechanics, the road friction coefficient φ (that is, the wheel adhesion coefficient) changes with the change of the wheel slip rate S. Fig. 3 provides a comparative diagram of the relationship between wheel slip and longitudinal adhesio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com