Method for producing titanium nitride membrane at room temperature

A technology for titanium nitride and thin films, which is applied in the field of preparing titanium nitride thin films at room temperature, can solve the problems of few reports on titanium nitride thin films, and achieve the effects of convenient operation, good adhesion and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: A titanium nitride thin film was prepared on a Ti surface by an electrophoretic deposition method at room temperature. After cleaning, the Ti sheet (thickness 0.25mm, area 3.14cm 2 ) is fixed in the electrolytic cell, and the opposite electrode adopts a metal Pt sheet, the potential of the potentiostat is adjusted to 10V, the distance between the electrodes is 1cm, and the nano-titanium nitride suspension containing 10g / L is used for electrophoretic deposition for 1 hour to obtain Dark yellow TiN film. The obtained TiN thin film can be used in decorative materials. The current-time curve of the electrophoretic deposition process is shown in Fig. 3 .

Embodiment 2

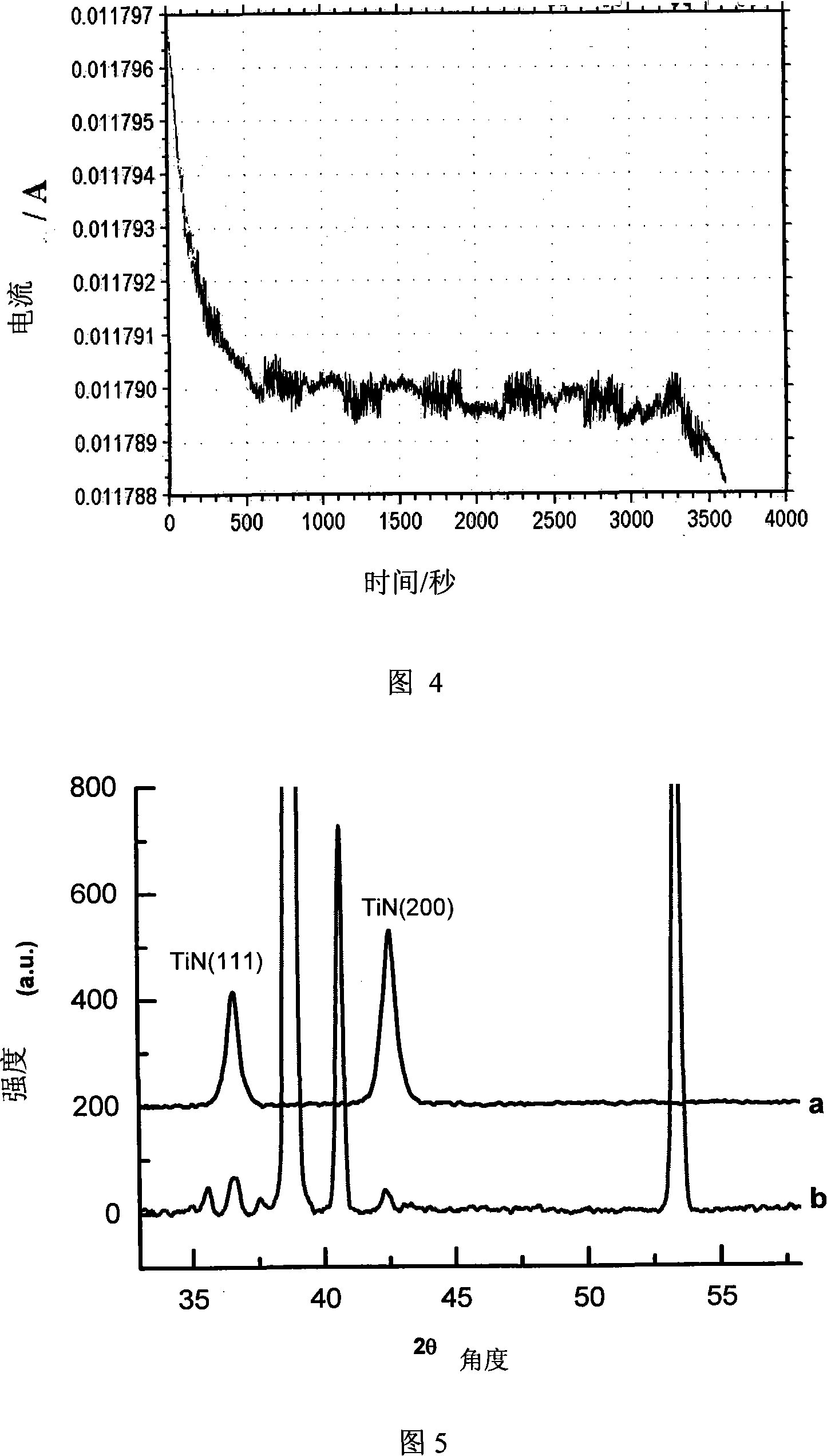

[0015] Example 2: A titanium nitride film was prepared on the surface of Ni / Cr stainless steel by electrophoretic deposition. Cleaned stainless steel (with an area of 3.14cm 2 ) is fixed in the electrolytic cell, the counter electrode adopts a metal Pt sheet, the potential of the potentiostat is adjusted to 20V, and the nano-titanium nitride suspension containing 210g / L is used for electrophoretic deposition for 0.5 hour to obtain a golden yellow TiN film. The current-time curve of the electrophoretic deposition process is shown in Fig. 4 .

Embodiment 3

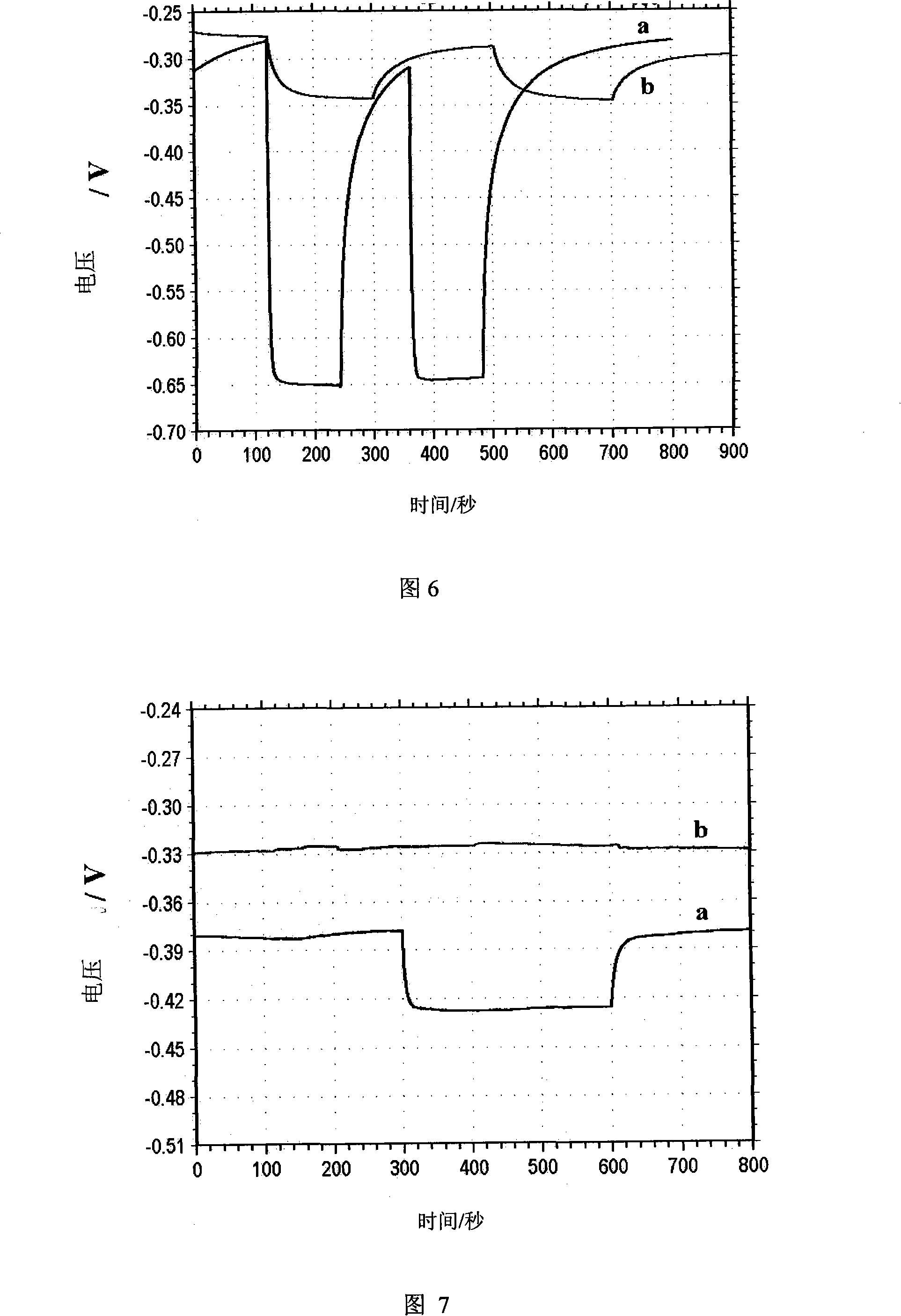

[0016] Embodiment 3: prepare titanium nitride thin film on Ti surface by electrophoretic deposition method, after cleaning Ti (area is 1cm 2 ) was fixed in the electrolytic cell, using a metal Pt sheet as the counter electrode, adjusting the input voltage of the DC stabilized voltage to 10V, 5g / L nano-titanium nitride suspension, and electrophoretic deposition for 8 hours to obtain a blue TiN film. The comparison of the XRD results after electrophoretic deposition and the XRD results of TiN powder is shown in Figure 5. It can be seen from the figure that TiN has been successfully deposited on the substrate surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com