Method of manufacturing two-dimension periodic semi-sphere shell dot matrix of large scale zinc oxide

A two-dimensional periodic, zinc oxide technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of unreported periodic spherical shell lattice structure of zinc oxide material, achieve low cost, Simple method and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

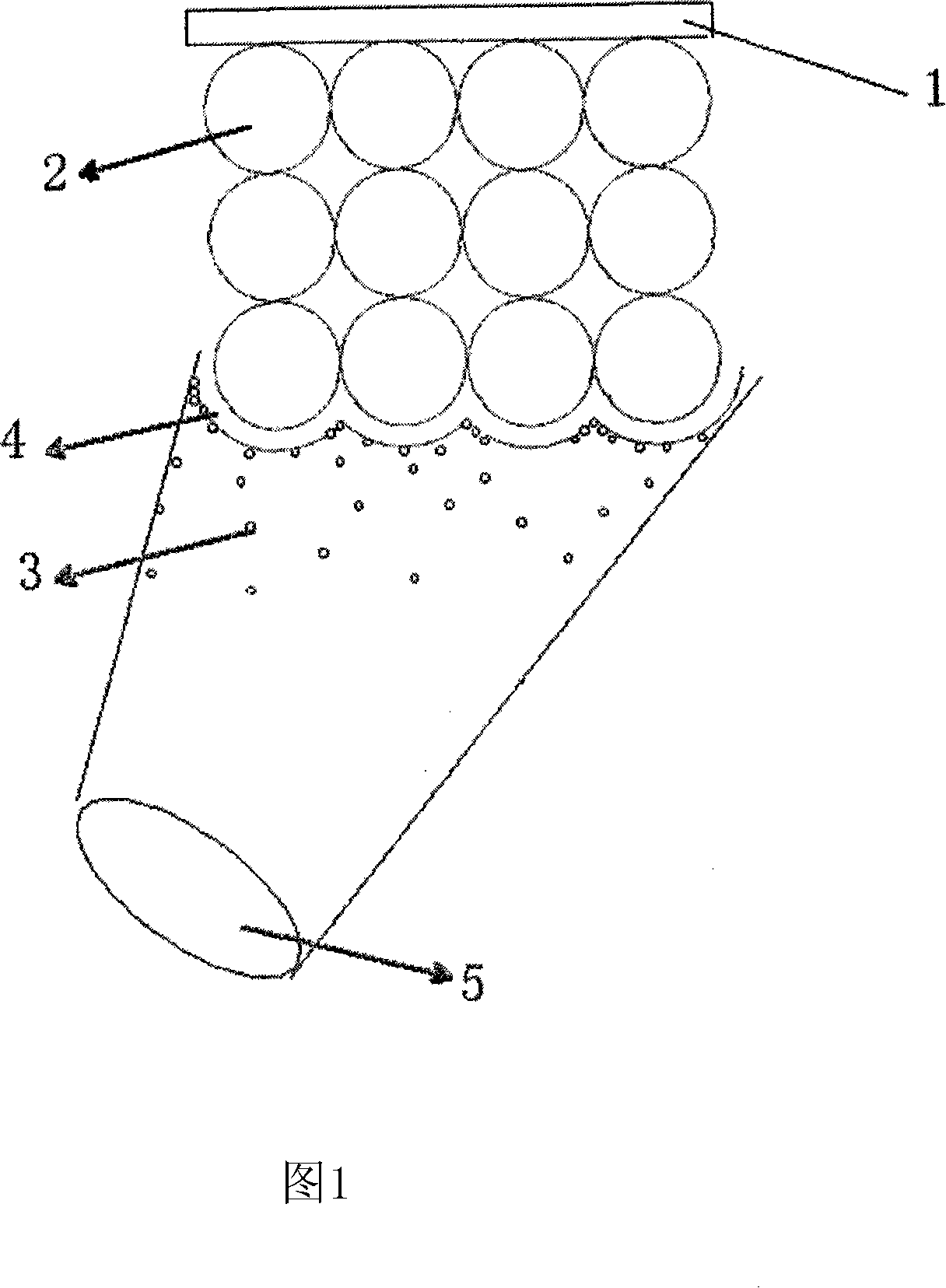

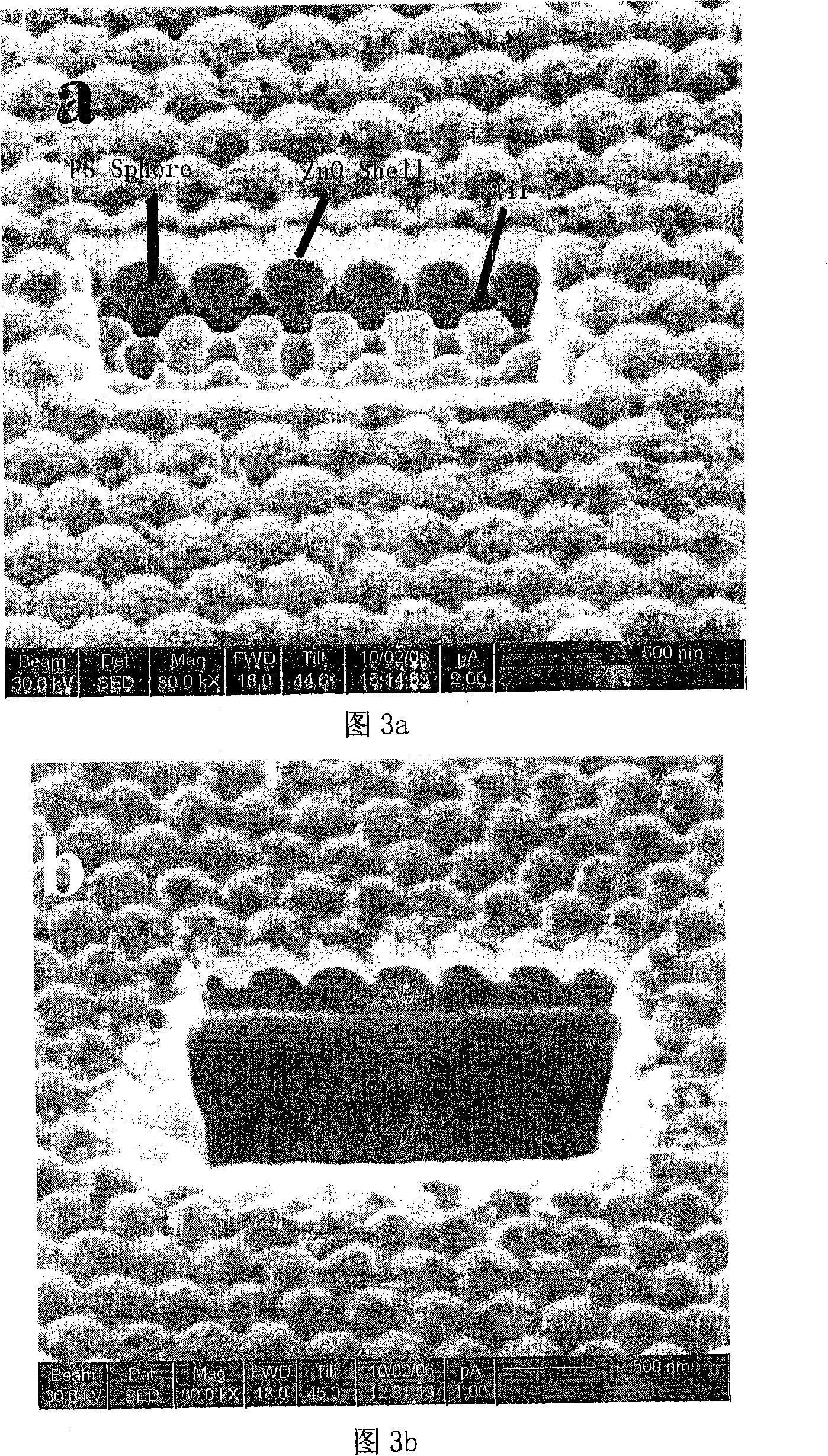

[0024] A method for preparing a large-scale zinc oxide two-dimensional periodic hemispherical shell lattice according to the present invention, which includes the following steps: Fig. 1 is a schematic diagram of the growth device of the present invention, wherein, 1 is a substrate material, and 2 is polystyrene Colloidal crystal, 3 is zinc oxide atomic cluster, 4 is spherical shell, 5 is zinc oxide target.

[0025] Preparation of Opal Structural Templates:

[0026] Substrate material: quartz wafer, silicon wafer or ITO glass, rectangular or square (1cm-5cm).

[0027] Assembly materials: silicon dioxide (100nm-600nm) and polystyrene (PS) (200nm-900nm) monodisperse microspheres (monodispersity<5%).

[0028] Growth process: using the vertical deposition method or pulling method, the substrate is immersed in the suspension of microspheres, and as the liquid level drops or the substrate is pulled, a multi-layer or single-layer colloidal crystal (opal) template can be obtained . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com