Room temperature hydrostatic liquid extrusion pressing deforming strengthening technique of magnesium alloy

A technology of hydrostatic extrusion and deformation strengthening, applied in the field of room temperature hydrostatic extrusion deformation strengthening process of magnesium alloys, can solve the problems of narrow processing parameter window, low mold service life, growth of grain structure, etc. Surface finish, less die wear, uniformity across section and length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

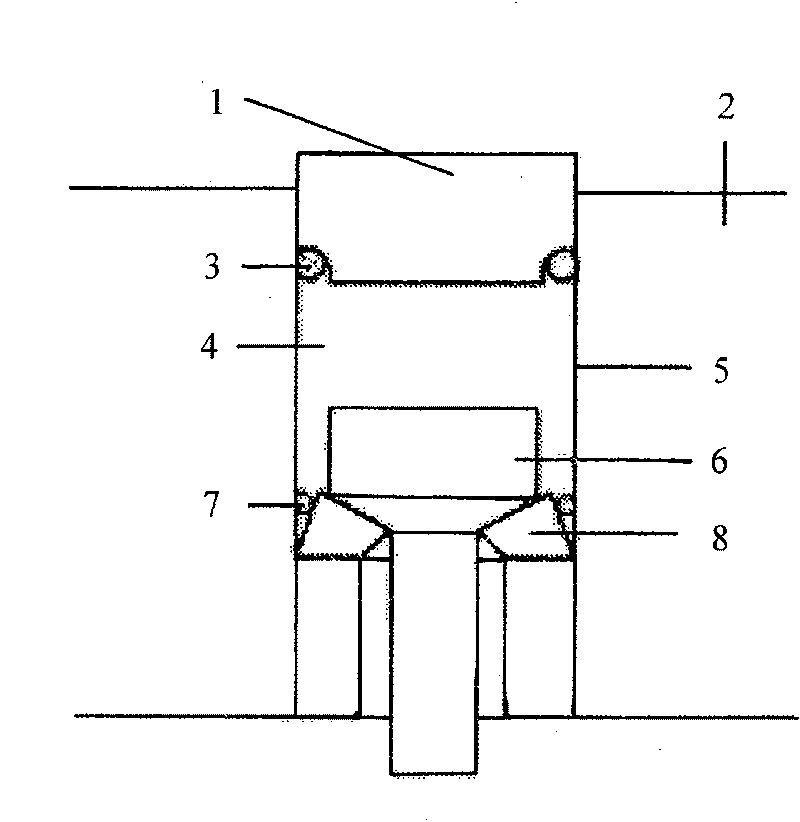

[0023] The design extrusion ratio is 1.1, and the size of the extrusion die 8 is φ10mm (that is, the diameter of the finished product after extrusion, the same below). The process steps are as follows:

[0024] 1. According to the pre-designed extrusion ratio, the processing size of the ZK60 magnesium alloy billet is calculated to be φ10.49mm, and the magnesium alloy billet 6 is turned according to the calculated size. The size of the guide section is φ10mm×6mm, and it is ensured that the guide section and the deformation section have a unilateral 20°±0.2° taper transition to ensure the sealed connection between the blank and the extrusion die 8 . The 20°±0.2° taper between the guide section and the deformation section refers to the angle between the cone surface and the vertical center line. If the angle is too small, the sealing cannot be achieved during the extrusion process; if it is too large, it will cause stress concentration and cause the billet to appear. Cracks, so 2...

Embodiment 2

[0032] The design extrusion ratio is 1.5, the extrusion die size is φ10mm, and the process steps are as follows:

[0033] 1. According to the pre-designed extrusion ratio, the processing size of the ZK60 magnesium alloy billet is calculated to be φ12.25mm, and the magnesium alloy billet 6 is turned according to the calculated size. The size of the guide section is φ10mm×6mm, and the transition between the guide section and the deformed section is guaranteed to be a unilateral 20°±0.2° taper to ensure the sealed connection between the billet and the extrusion die.

[0034] 2. Use the sealing ring 7 (φ45×2.5) to seal the extrusion die, then assemble the processed billet 6 with the extrusion die 8, and use grease to seal the joint between the billet 6 and the extrusion die 8 And the lubrication treatment of the deformation section.

[0035] 3. Turn on the press, raise the extrusion cylinder 2, install the assembled billet 6 and extrusion die 8 into the extrusion cylinder 5, then...

Embodiment 3

[0041] The design extrusion ratio is 2.2, the extrusion die size is φ10mm, and the process steps are as follows:

[0042] 1. According to the pre-designed extrusion ratio, the processing size of the ZK60 magnesium alloy billet is calculated to be φ14.83mm, and the magnesium alloy billet 6 is turned according to the calculated size. The size of the guide section is φ10mm×6mm, and the transition between the guide section and the deformed section is guaranteed to be a unilateral 20°±0.2° taper to ensure the sealed connection between the billet and the extrusion die.

[0043] 2. Use the sealing ring 7 (φ45×2.5) to seal the extrusion die, then assemble the processed billet 6 with the extrusion die 8, and use grease to seal the joint between the billet 6 and the extrusion die 8 And the lubrication treatment of the deformation section.

[0044] 3. Turn on the press, raise the extrusion cylinder 2, install the assembled billet 6 and extrusion die 8 into the extrusion cylinder 5, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com