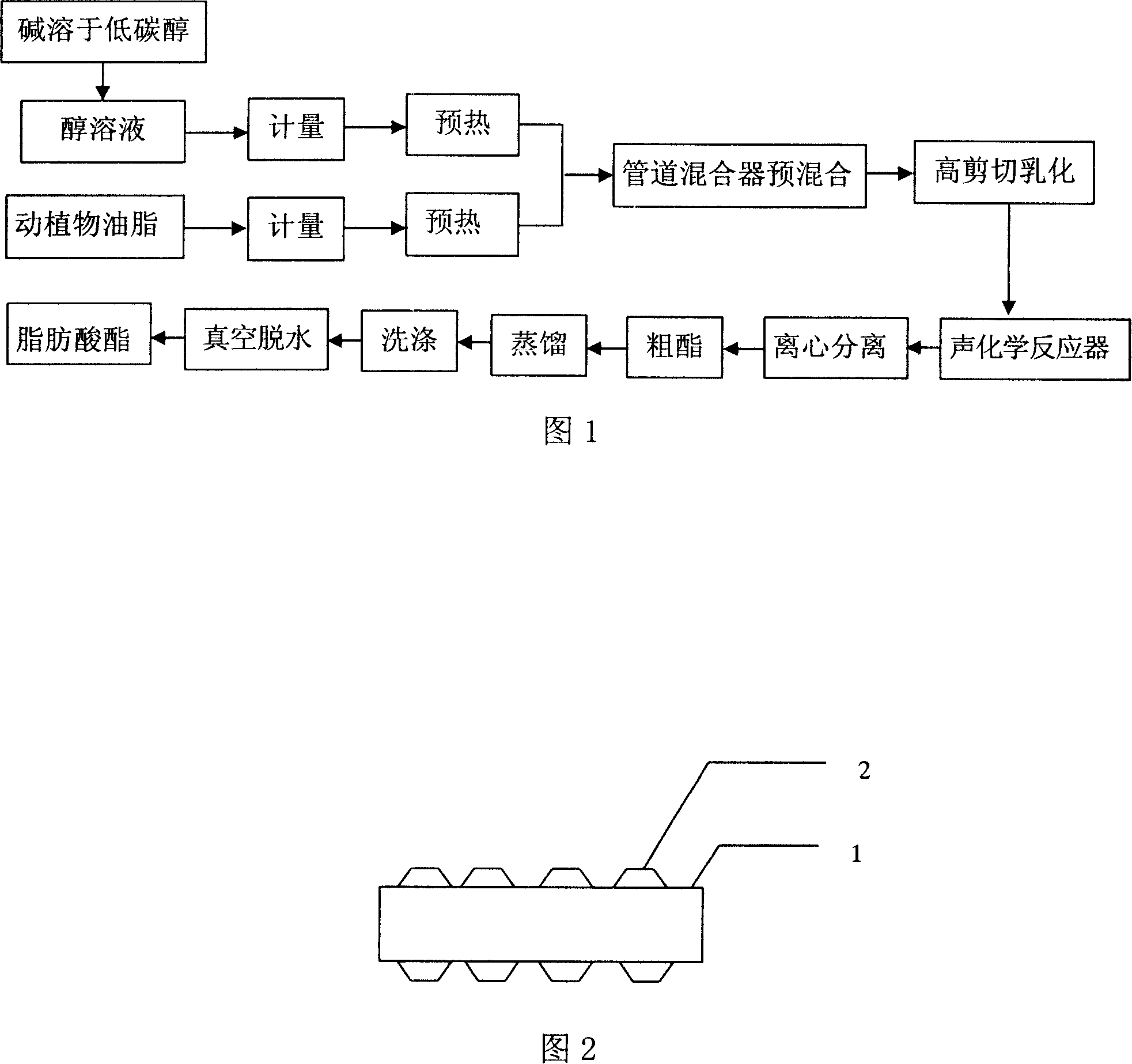

Method for manufacturing fatty acid ester continuously in ultrasonic field

A fatty acid ester and ultrasonic field technology, which is applied in the fields of renewable energy, chemical intermediates, and pesticide auxiliaries, can solve the problems of difficult amplification of ultrasonic equipment, large amount of catalyst, and complicated post-treatment, so as to reduce the amount of catalyst and be easy to control , the effect of continuous process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Raw materials: palm oil, methanol, sodium hydroxide

[0026] Dissolve 1.2 grams of sodium hydroxide in 600mL of methanol to obtain an alcohol solution, store it in a tank, and store 2000mL of palm oil in another tank. After passing through the flowmeter, the two liquids are sent to the heat exchanger by the pump for preheating After preheating, the temperature of methanol is 43-45°C, and that of oil is 80-83°C. Then it is pre-mixed by a pipeline mixer, then enters a high-shear emulsifying disperser, and then continuously enters a 28kHz, 300W sonochemical reactor, and the liquid flowing out from the other end of the reactor is centrifuged to obtain crude ester, which is distilled to remove methanol Afterwards, wash once with 0.3mol / L dilute sulfuric acid 40mL, wash twice with tap water, 120mL each time, and then dehydrate at 105°C under a vacuum of 0.03MPa to obtain fatty acid methyl esters, namely biodiesel. Determination, the reaction conversion rate can reach 99.1%. ...

Embodiment 2

[0028] Raw materials: soybean oil, methanol, sodium hydroxide

[0029] Dissolve 1.8g of sodium hydroxide in 600ml of methanol to obtain an alcohol solution, store it in a tank, store 2000mL of soybean oil in another tank, and send the two liquids into the heat exchanger for preheating after passing through the flowmeter After preheating, the temperature of methanol is 50-53°C, and that of oil is 92-95°C. Then it is pre-mixed by a pipeline mixer, then enters a high-shear emulsifying disperser, and then continuously enters a sonochemical reactor with a power of 200W. This sonochemical reactor has two frequencies-25kHz and 50kHz. During work, these two The frequency of ultrasonic waves acts on the liquid at the same time. The liquid flowing out from the other end of the reactor was centrifuged to obtain crude ester. After the crude ester was distilled to remove methanol, it was washed once with 60 mL of 0.4 mol / L dilute phosphoric acid and twice with 120 mL of tap water. Then, a...

Embodiment 3

[0031] Raw materials: palm oil, ethanol, potassium hydroxide

[0032] Dissolve 1.8g of potassium hydroxide in 1500ml of ethanol to obtain an alcohol solution, store it in a tank, store 2000mL of palm oil in another tank, and send the two liquids into the heat exchanger for preheating by the pump after passing through the flowmeter , after preheating, the temperatures of ethanol and oil are both 75-78°C. Then it is pre-mixed by a pipeline mixer, then enters a high-shear emulsification disperser, and then continuously enters a 40kHz, 200W sonochemical reactor. The liquid flowing out from the other end of the reactor was centrifuged to obtain crude ester. After the crude ester was distilled to remove methanol, it was washed once with 100 mL of 0.3 mol / L dilute hydrochloric acid and twice with tap water, 150 mL each time, and then heated at 100°C. The fatty acid ethyl ester is obtained by dehydration under the condition of a vacuum degree of 0.08 MPa, and the reaction conversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com