Transparent conductive film forming apparatus, multilayer transparent conductive film continuously forming apparatus and method of film forming therewith

A transparent conductive film and deposition technology, applied in coatings, circuits, photovoltaic power generation, etc., can solve the problems of low substrate speed, increased nozzle temperature, low use efficiency of raw materials, etc., to reduce the necessity of maintenance, improve The effect of using efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

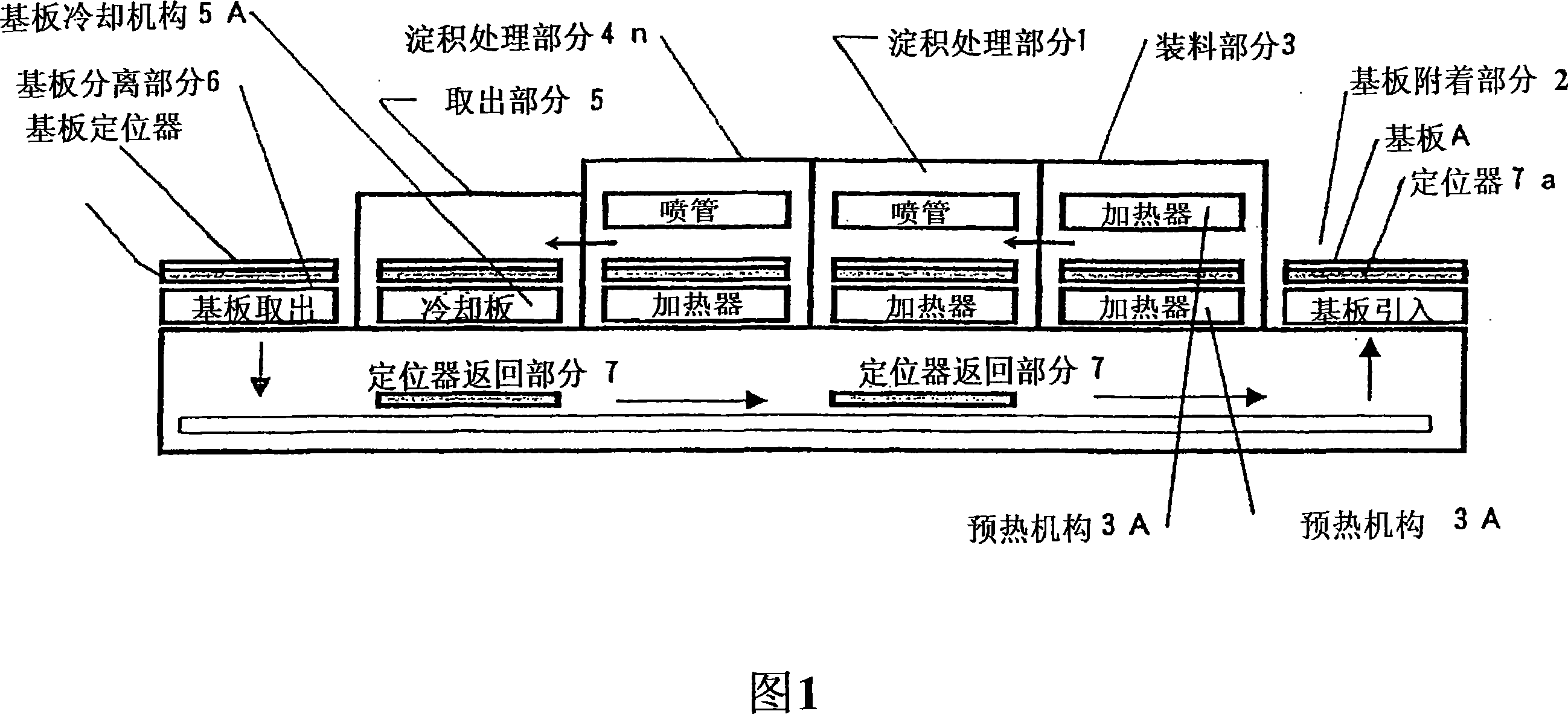

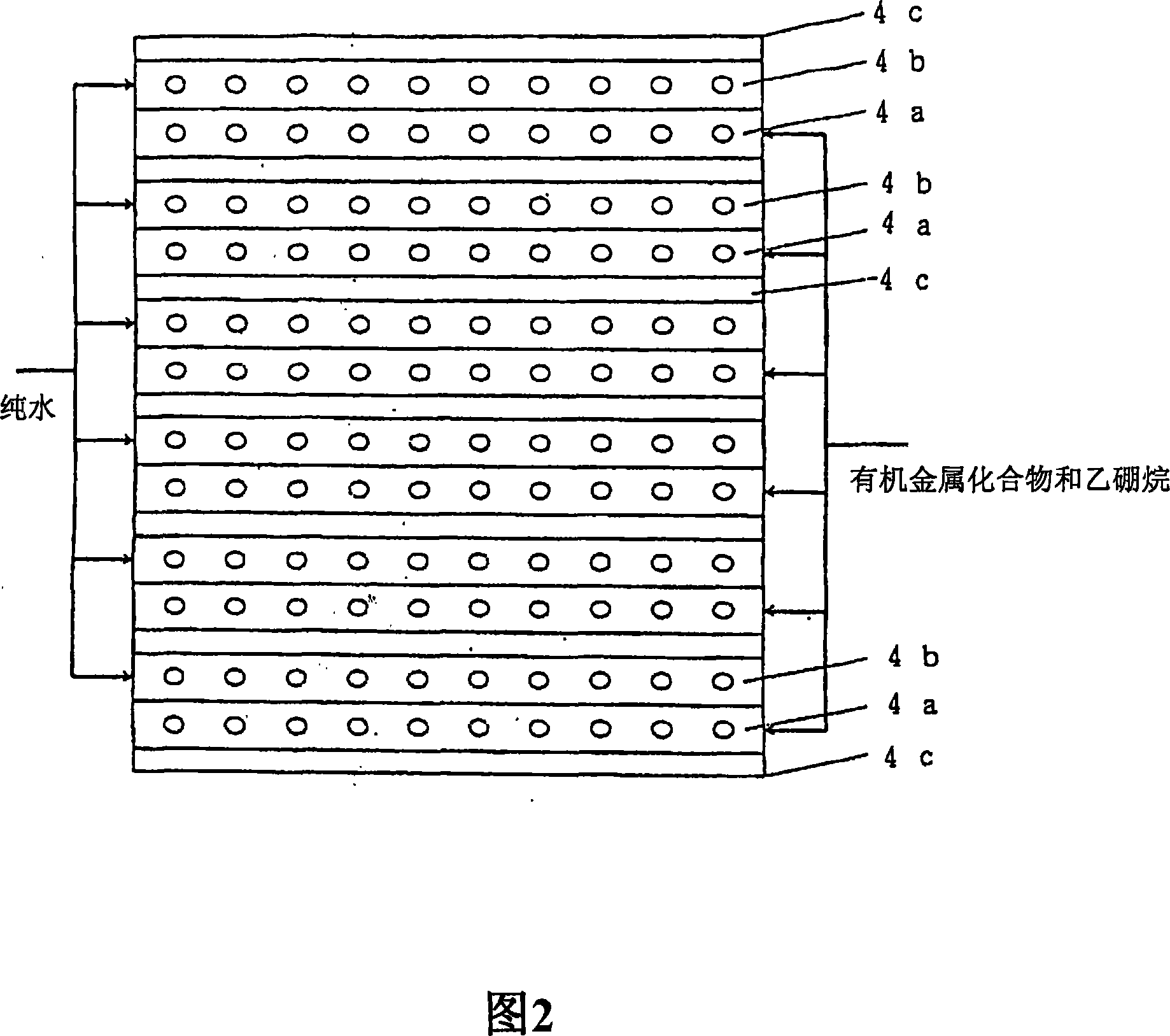

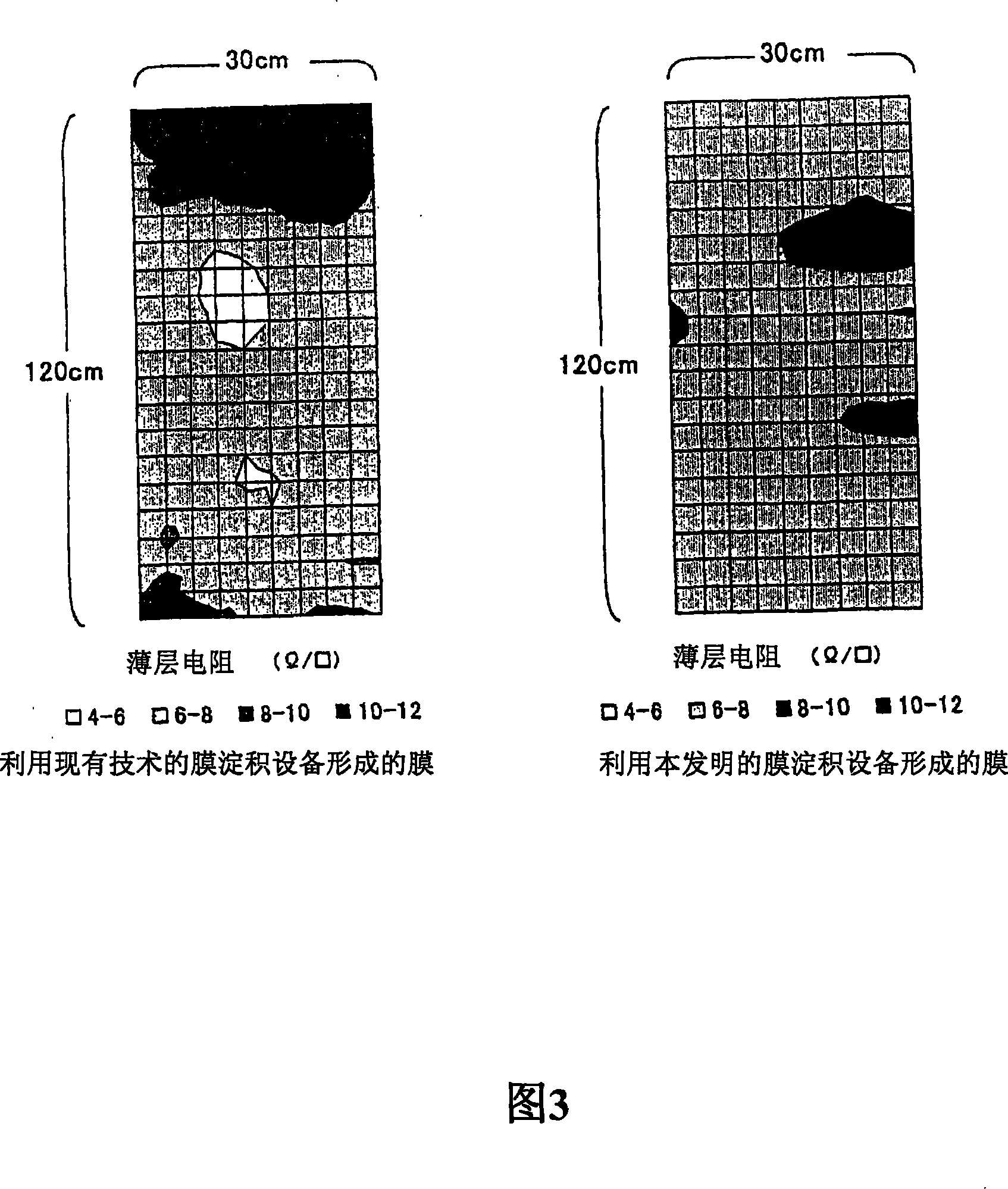

[0054] The present invention provides a film deposition apparatus for continuously forming a multilayer transparent conductive film including multiple layers of n-type semiconductors on a substrate and a method of forming the multilayer transparent conductive film. As shown in FIG. 1, the apparatus includes: a substrate attaching section 2, where a substrate A is attached to a positioner 7a in air; a loading section 3, where evacuation is performed; a multilayer deposition processing section 4, which includes two One or more deposition processing sections (41 to 4n) are used for heating the substrate by adding an organometallic compound (diethylzinc Zn(C 2 h 5 ) 2 ), diborane (B 2 h 6 ) and water (water vapor) react in the vapor phase, and use metal organic chemical vapor deposition (MOCVD) method to form a transparent conductive film comprising n-type semiconductor (such as ZnO) on the heated substrate; take out part 5, in Here, the substrate with the multilayer transpare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com