Technique for preparing gasoline by methanol

A methanol-to-gasoline and methanol vapor technology, which is applied in the petroleum industry, liquid hydrocarbon mixture recovery, etc., can solve problems such as difficult temperature control of intermediate products and ineffective extraction of dimethyl ether

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

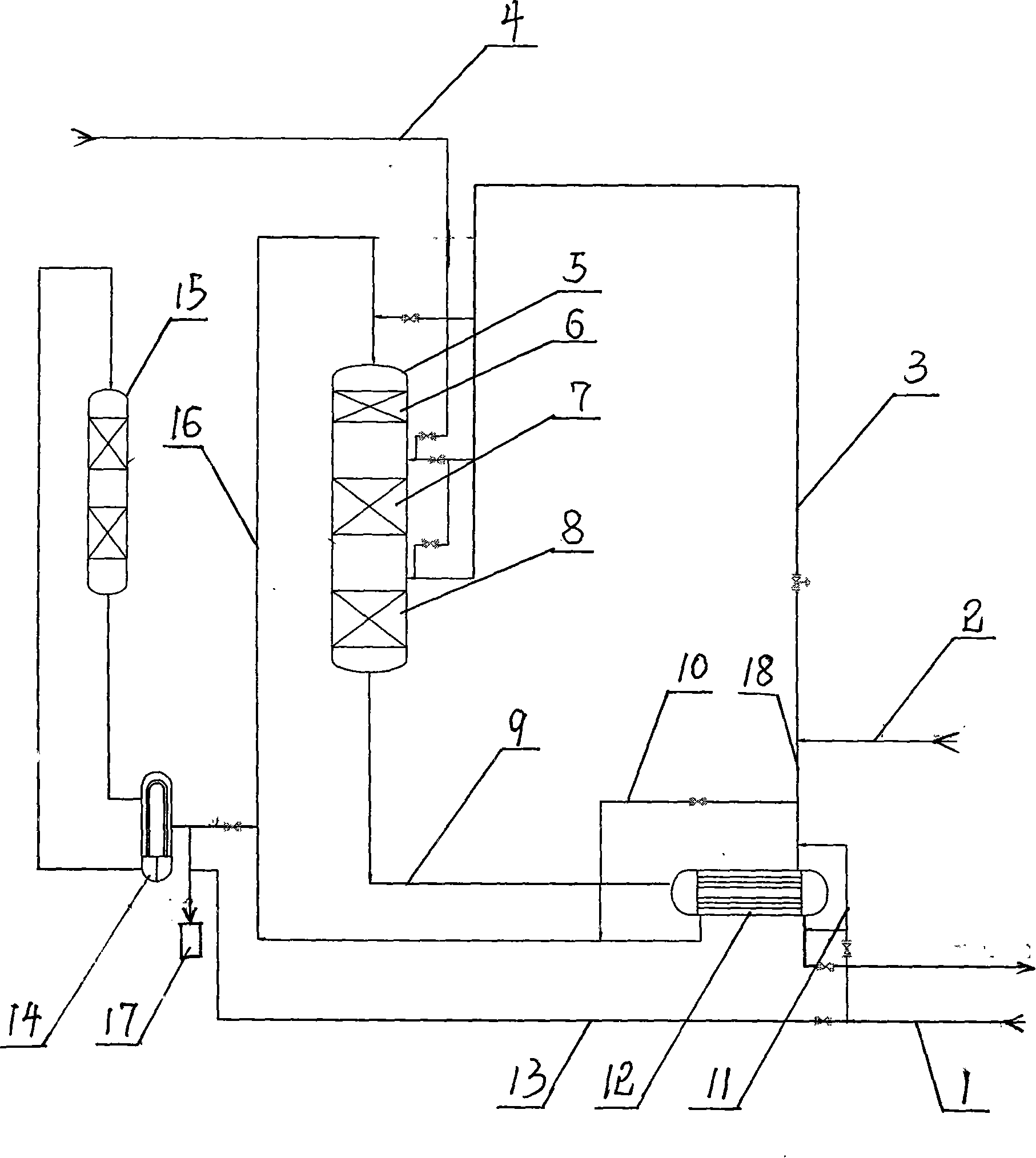

[0018] A methanol-to-gasoline technology, the steps include sending methanol vapor into a gasoline synthesis reactor to react to generate gasoline, and controlling the temperature of the reaction gas to be within the range of 300-400°C and pressure 2.3-2.1MPA, and at least There are three catalyst beds filled with ZSM-5 catalyst.

[0019] In the process of realizing the above process, the methanol vapor can also be heated up to the active temperature of the dimethyl ether catalyst and then sent to the dimethyl ether reactor. The methanol vapor generates dimethyl ether under the action of the catalyst of dimethyl ether; the dimethyl ether is produced The dimethyl ether obtained from the reactor, and part of the mixed gas of water and methanol are sent to the dimethyl ether rectification system for rectification to obtain pure dimethyl ether products.

[0020] Below in conjunction with accompanying drawing 1, the present invention is further described, as shown in the accompanyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com