Method and device for preventing coarse coal-gas from fluctuating in fixed bed type reactor

A reactor, fixed bed technology, applied in the field of gasification of heterogeneous raw material mixtures, can solve problems such as adverse effects on quality and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

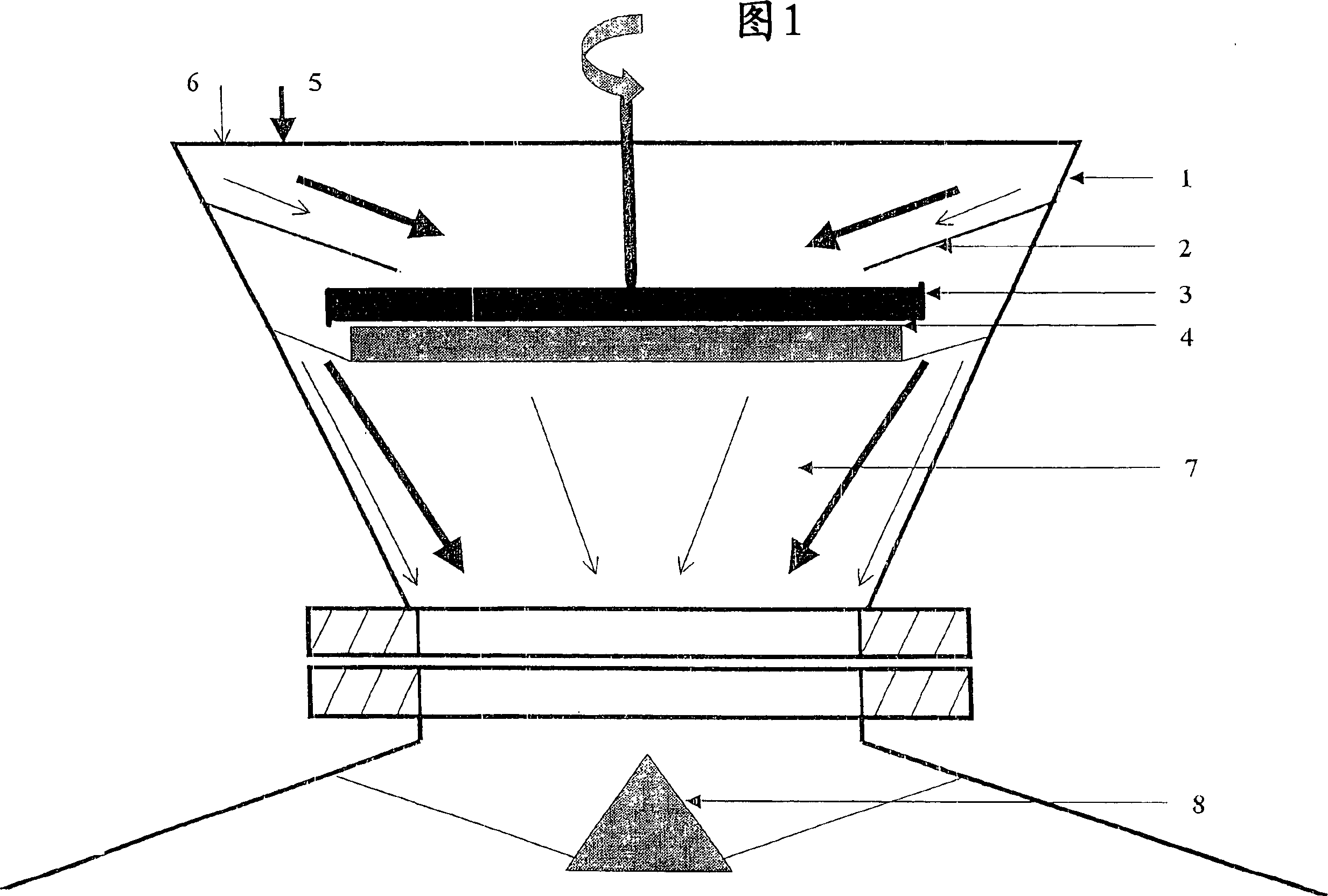

[0019] The present invention will be described in more detail by means of an embodiment in conjunction with FIG. 1 .

[0020] A guide plate 2 is provided above the discharge device in the pressure vessel 1, and its central opening is smaller than the diameter of the fixed disc 4 and the rotatable star discharge device 3 above it, and the blade design of the star discharge device In this way, the blades exert a radial force on the solid raw material when the star wheel is running, so that the raw material is forced into the cavity 7 . The stationary disk 4 and the walls of the cavity are forced to cool. The input of solid raw material 5 and blowing gas 6 is carried out at the top of the pressure vessel with a discharge device. The inner structure is designed in such a way that a forced flow of gas into the cavity is ensured through the outlet slot.

[0021] A solid raw material distributor is fixed on the top of the reactor. Diameters and angles are determined according to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com