Combined type all-closed smoke dust removal energy-saving firewood stove

A fully enclosed and combined technology, which is applied in heating methods, household stoves/stoves, and stoves/stoves with hot water devices. The flame is easily blown out by the airflow and other problems, so as to achieve good oxygenation effect, good oxygenation and combustion-supporting effect, and reduce the difficulty of ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

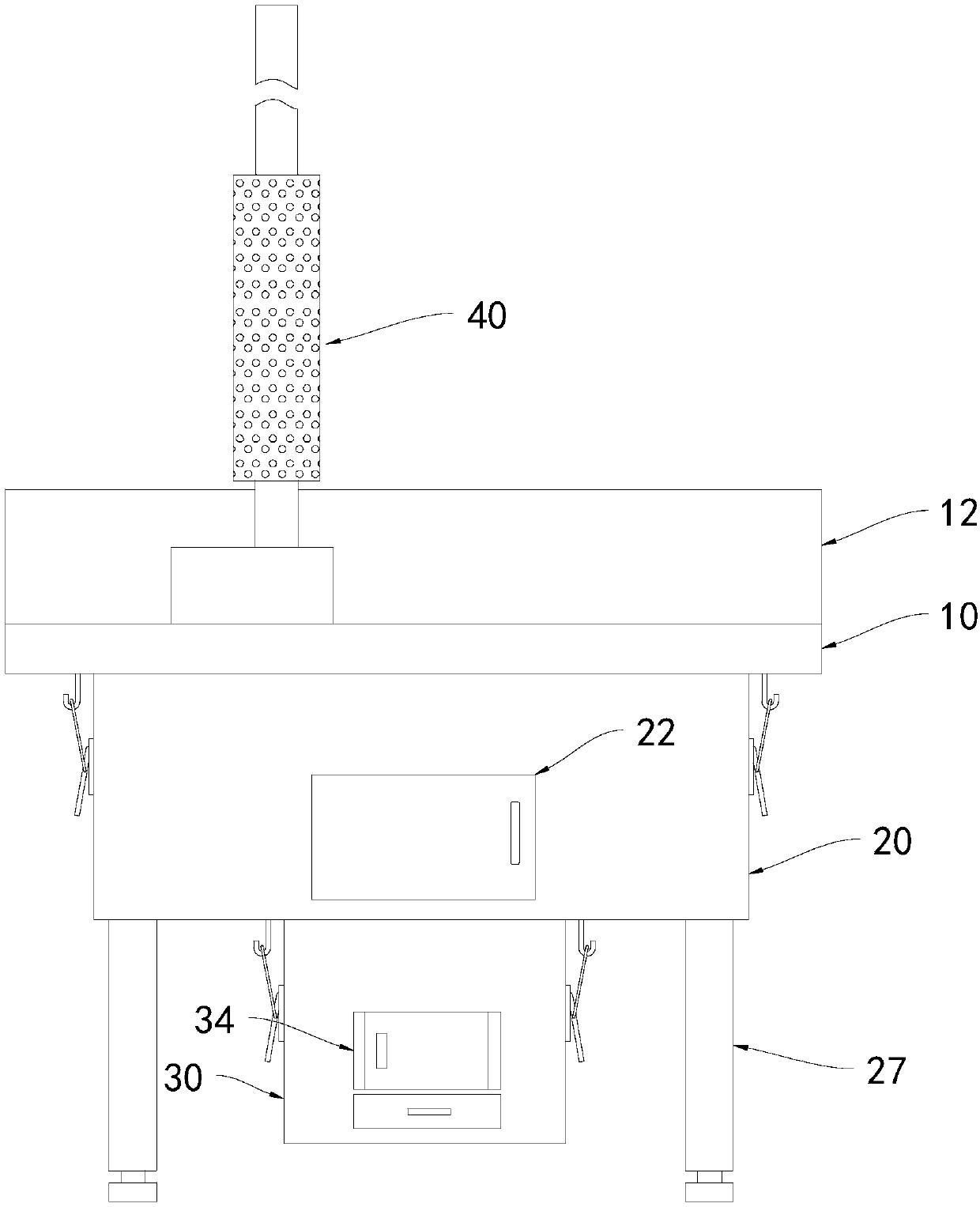

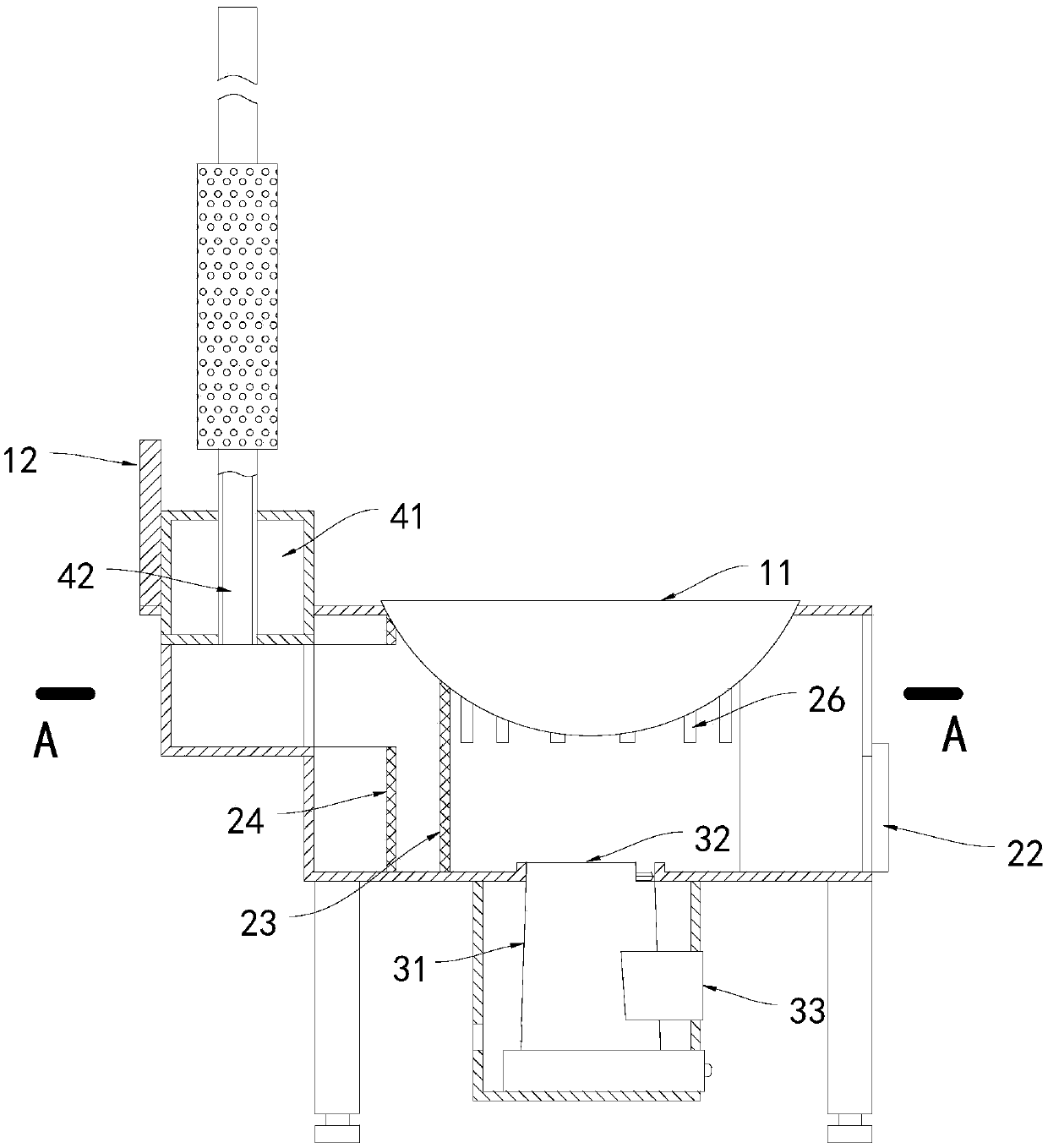

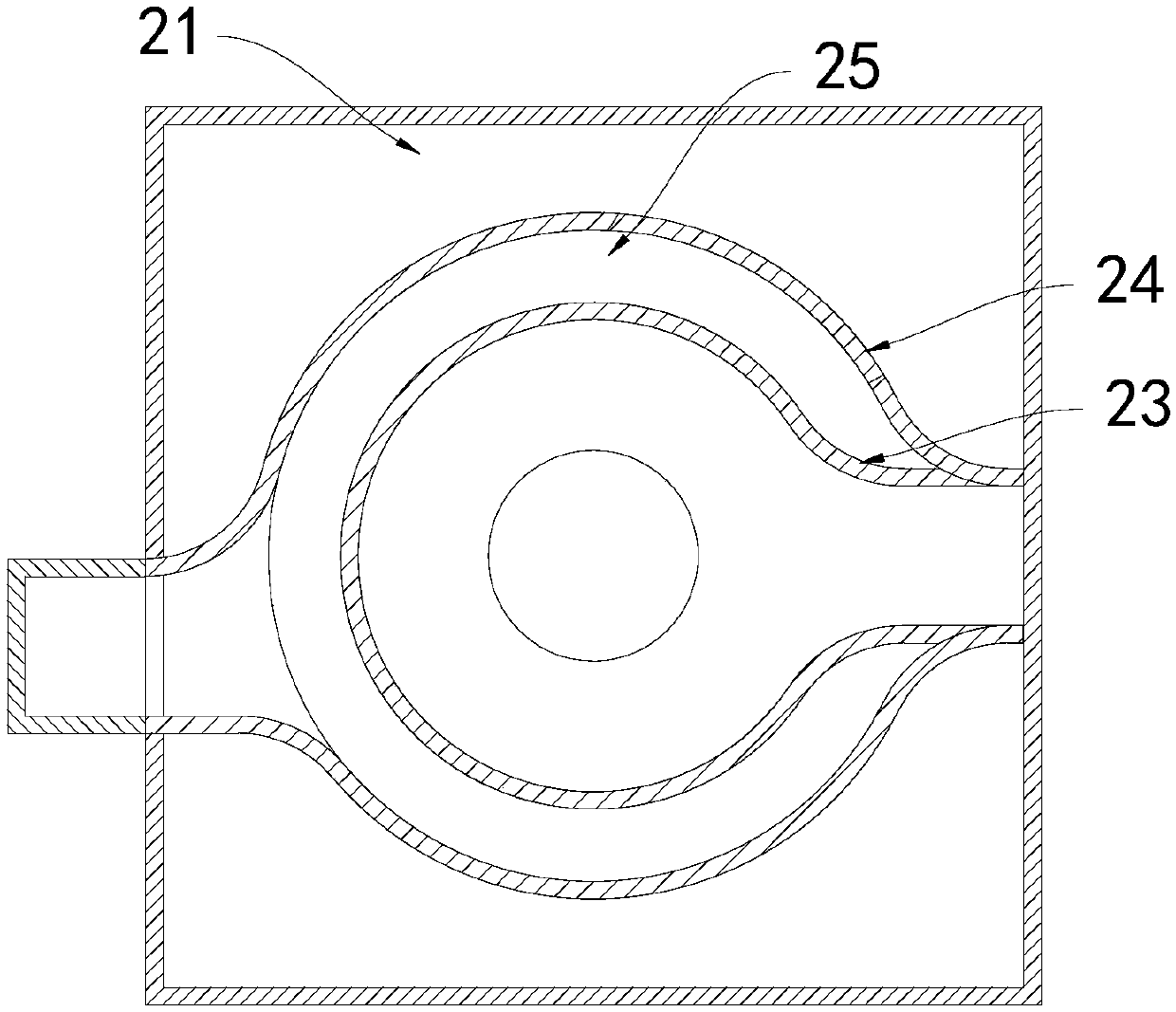

[0029] Embodiment: A combined fully enclosed smoke-removing and dust-removing energy-saving firewood stove, which is constituted as follows Figure 1 to Figure 6 As shown, it includes a stove body 20 and a table top 10 arranged on the upper end of the stove body 20, the table top 10 is provided with a gap for placing the pot 11, the stove body 20 is provided with a stove chamber 21, and the bottom of the stove body 20 is provided with an oxygen supply box. 30, an oxygen enrichment furnace 31 is provided in the oxygen supplement box 30; the upper end of the oxygen enrichment furnace 31 is provided with a gas outlet 32 connected with the hearth 21, and the gas outlet 32 is provided with a movable grate 38, and the oxygen enrichment furnace wall A supporting block for supporting the grate is provided on the top, and an air inlet 33 is provided in front of the lower end of the oxygen increasing furnace 31, and the air inlet 33 is provided with a damper 34; the furnace wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com