Highlight water-based automobile paint

An automotive paint, water-based technology, used in coatings, devices for coating liquids on surfaces, polyurea/polyurethane coatings, etc. The effect of saving raw materials, reducing production costs, reducing hazards and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Water-based automotive paint is divided into: finish varnish, organic pigment color paint (black, blue, green, red) and inorganic pigment color paint (white, yellow, iron red, orange red).

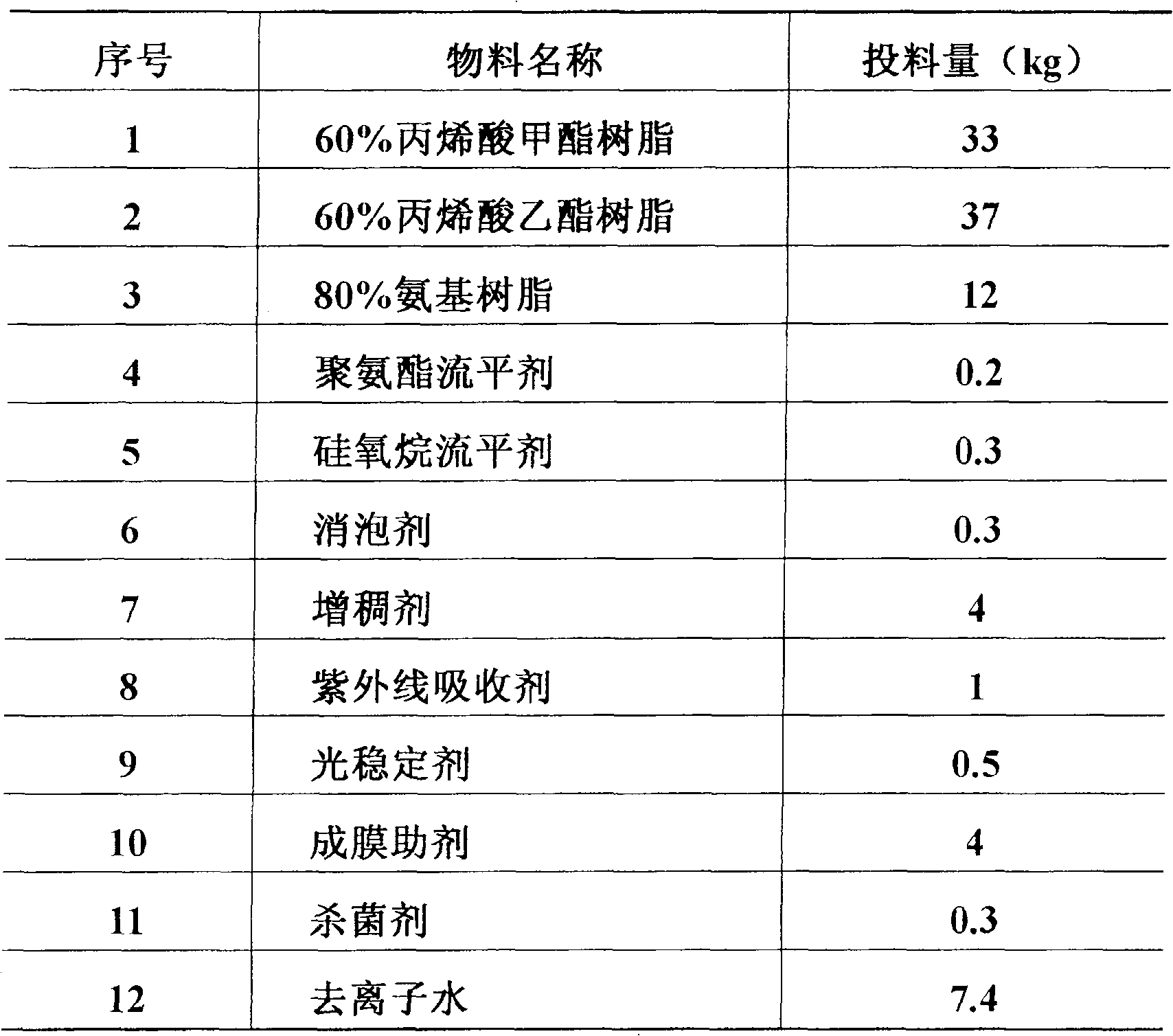

[0015] (1) Finish varnish (paint):

[0016]

[0017] The above materials are put into the tank under the stirring of the disperser, fully stirred for 20 minutes to make them uniform, and the physical and chemical indicators are tested. After passing the test, they are packaged in separate tanks, which is the finished product.

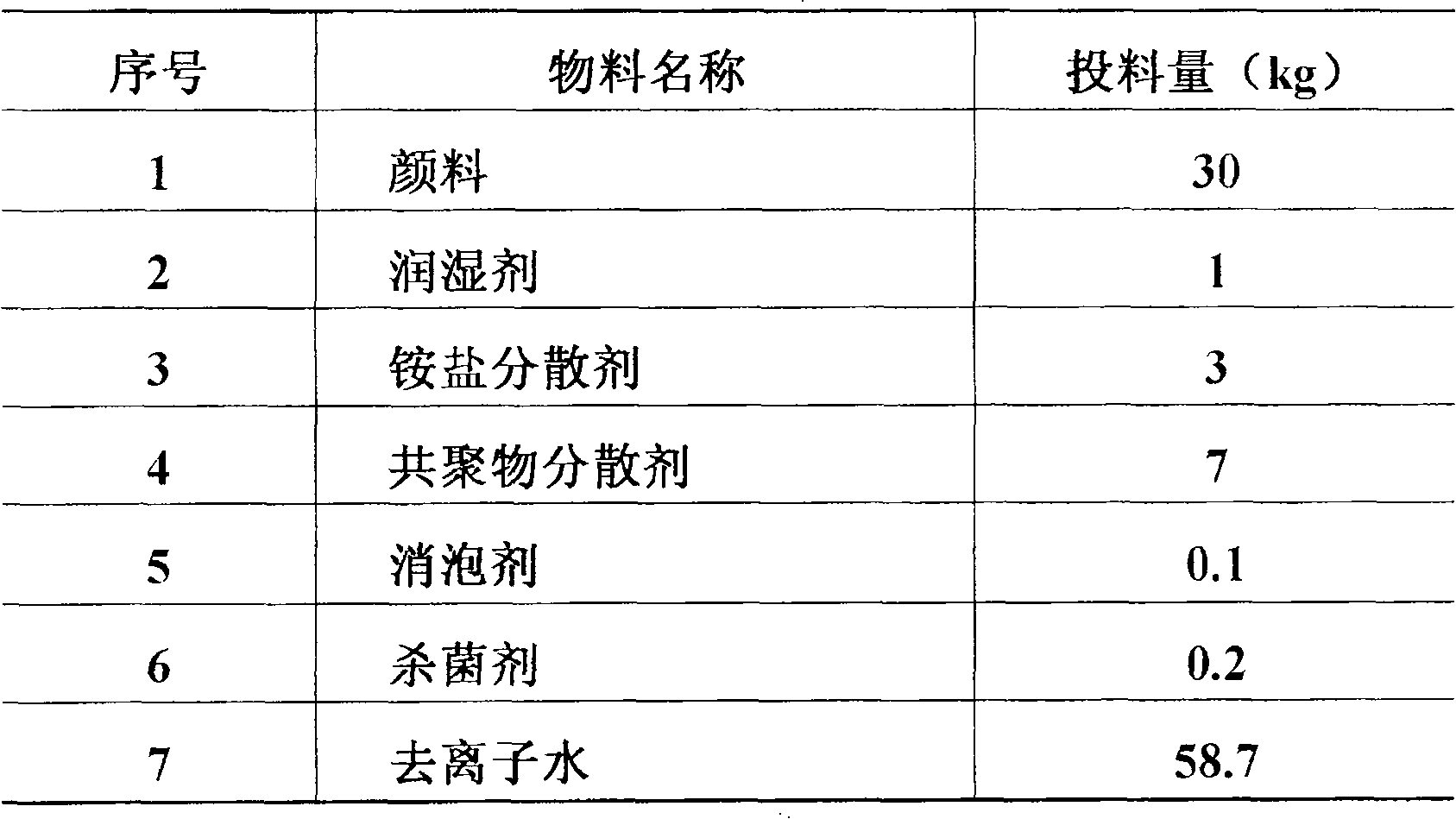

[0018] (2), organic pigment paste (black, blue, green, red)

[0019]

[0020] Put the deionized water into the tank, the speed of the disperser is 500-1000 rpm, and put in the wetting agent, ammonium salt dispersant, copolymer dispersant, defoamer, pigment in turn, after stirring for 20-30 minutes, pass through the sand mill Grind to below 15μm, then add bactericide and stir for 10 minutes.

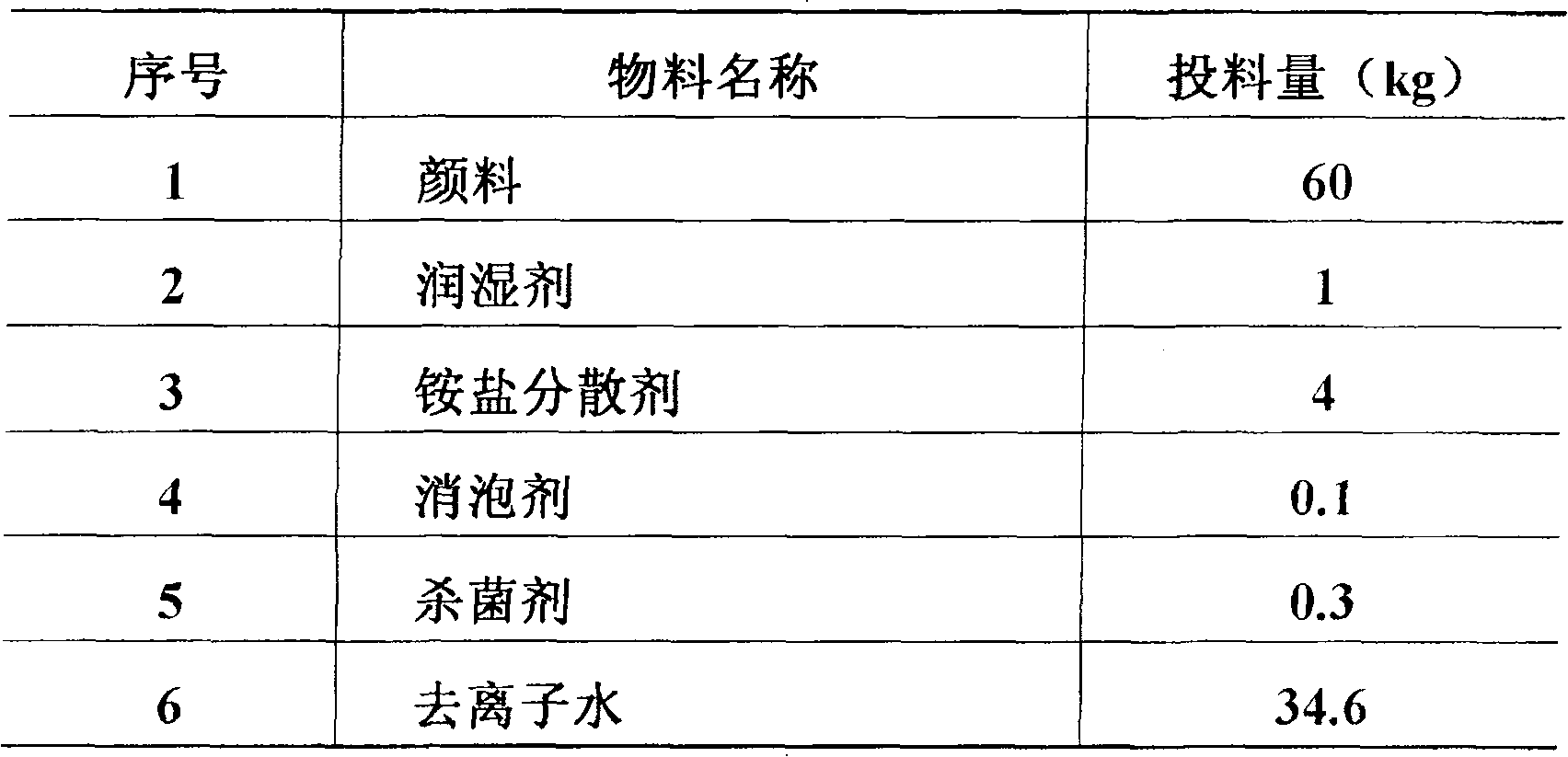

[0021] (3), inorganic pigment paste (white, yellow, iron re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com