Method for producing natural blue pigment

A production method and technology for blue pigment, applied in the field of bioengineering, can solve the problems of low reaction rate, unable to prepare green, purple, brown, difficult to industrialized production, etc., to shorten the reaction time, save the production cost, and improve the health care function. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 , Aspergillus niger fermentation to obtain β-glucosidase

[0025] Seed medium formula (g / L): 20g soluble starch, 10g glucose, KH 2 PO 4 1g, MgSO 4 1g, NaNO 3 2g, yeast extract 5g, pH4.

[0026] Fermentation medium formula (g / L): KH 2 PO 4 2g, MgSO 4 ·7H 2 O 0.2g, (NH 4 ) 2 SO 4 1.6g, bran is 3% of the liquid content, pH6.

[0027] According to the formula of the seed medium, the seed culture is carried out in a 250ml Erlenmeyer flask, the filling volume is 25ml, and the inoculation volume is about 2.0×10 spores 8 , the rotation speed of the shaker was 200 rpm, the culture temperature was 30° C., and the culture time was 44 h.

[0028] According to the formula of the fermentation medium, the fermentation culture was carried out in a 250ml Erlenmeyer flask with a liquid volume of 15ml, an inoculation volume of 750μl, a shaker rotation speed of 200rpm, a culture temperature of 30°C, and a culture time of 72h.

[0029] The β-glucose enzyme liquid...

Embodiment 2

[0030] Example 2 , Aspergillus niger fermentation to obtain β-glucosidase

[0031] Seed medium formula (g / L): soluble starch 15g, glucose 8g, KH 2 PO 4 0.8g, MgSO 4 0.8g, NaNO 3 1.8g, yeast extract 4.5g, pH4.

[0032] Fermentation medium formula (g / L): KH 2 PO 4 1.8g, MgSO 4 ·7H 2 O 0.15g, (NH 4 ) 2 SO 4 1.3g, bran is 5% of the liquid content, pH7.5.

[0033] According to the formula of the seed medium, the seed culture is carried out in a 250ml Erlenmeyer flask, the filling volume is 25ml, and the inoculation volume is about 2.0×10 spores 8 , the rotation speed of the shaker was 200 rpm, the culture temperature was 30° C., and the culture time was 48 h.

[0034] According to the formula of the fermentation medium, the fermentation culture was carried out in a 250ml Erlenmeyer flask with a liquid volume of 15ml, an inoculation volume of 750μl, a shaker rotation speed of 200rpm, a culture temperature of 30°C, and a culture time of 74h.

[0035] The β-glucose...

Embodiment 3

[0036] Example 3 , the preparation of gardenia blue pigment

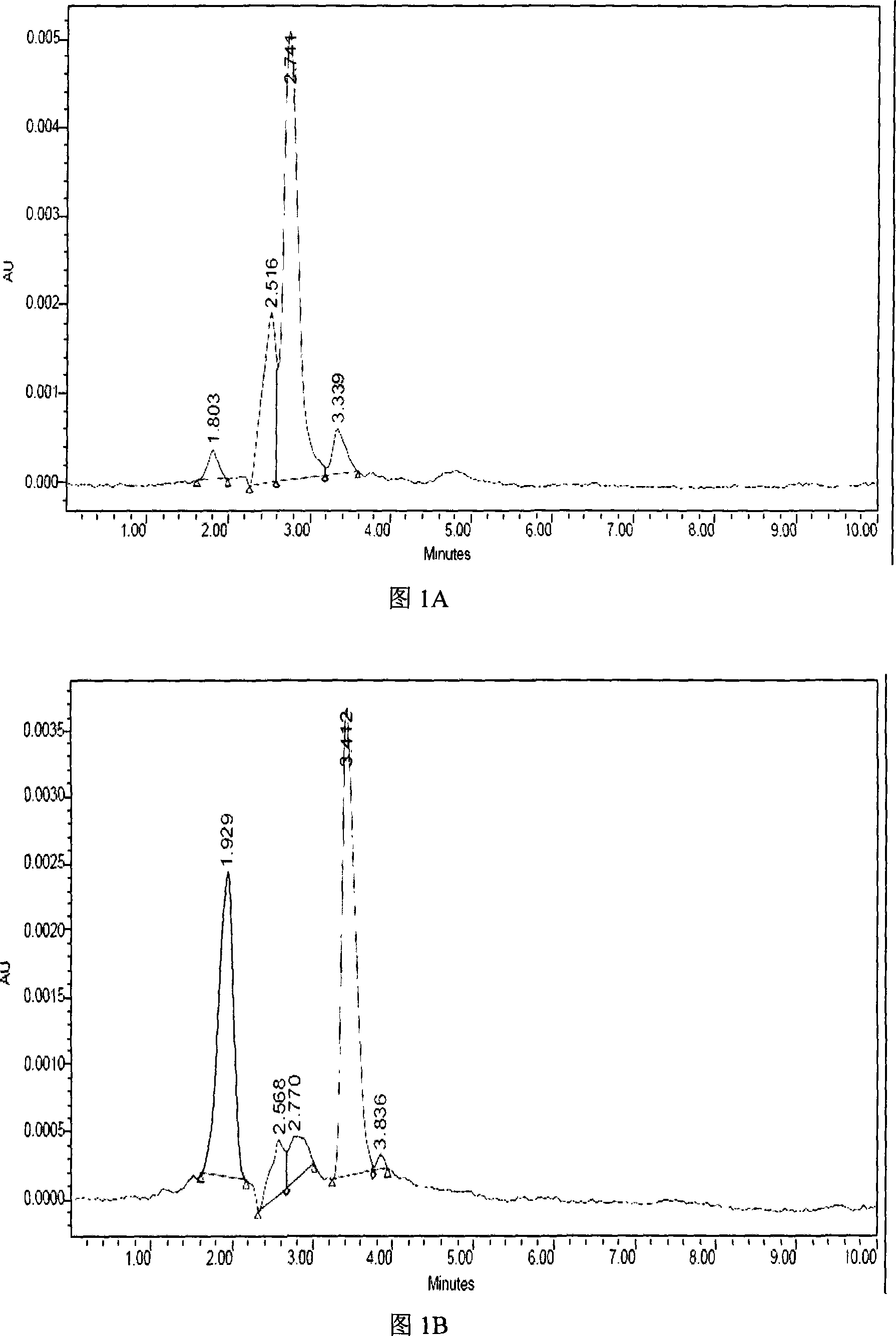

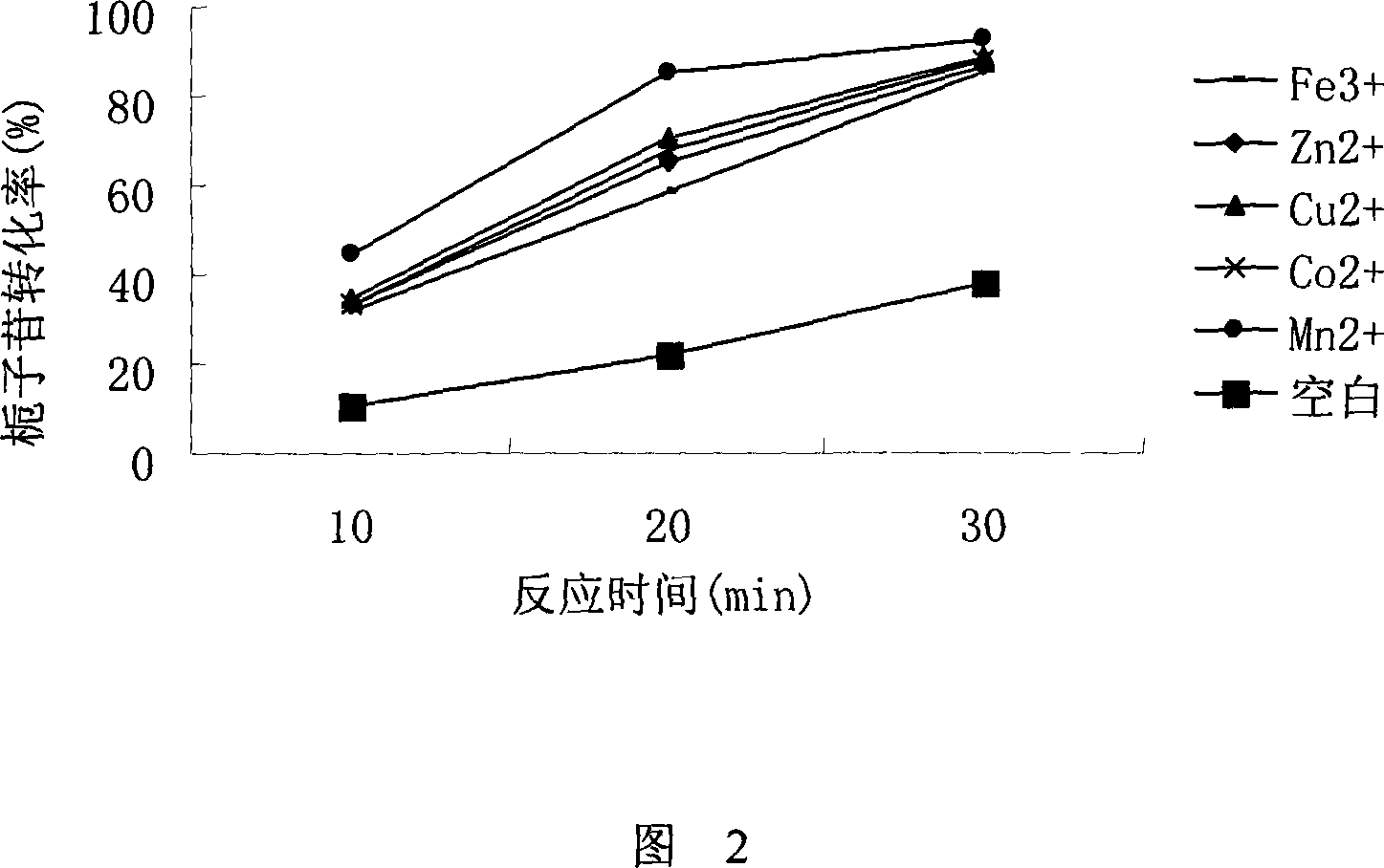

[0037] Prepare a geniposide solution with a weight ratio concentration of 0.05%, take 4ml, and add an appropriate amount of the enzyme solution obtained in Examples 1 and 2 and 100 μl each of the β-glucosidase (FLUKA company) derived from bitter almonds as shown in Table 1 , and selectively add a metalloenzyme promoter (according to the volume of the reaction solution, the amount per ml is 0.02-0.25μg), react at 50-60°C for 30-120min, take samples every 10min during the reaction, and measure it by HPLC method The content of geniposide (wherein the HPLC collection of illustrative plates before and after reaction of 2# sample is as shown in Figure 1A and 1B, all the other samples are basically the same, so omit), and calculate conversion rate (conversion rate=1-recorded geniposide content / initial geniposide content), the results are shown in Table 2.

[0038] Then add different amino acids to the reaction solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com