Leadframe, semiconductor package and method for producing the same

A lead frame and semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve the problems of limitation improvement, minimum length of bonding wire and height limitation of bonding wire, etc., and achieve the effect of reducing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

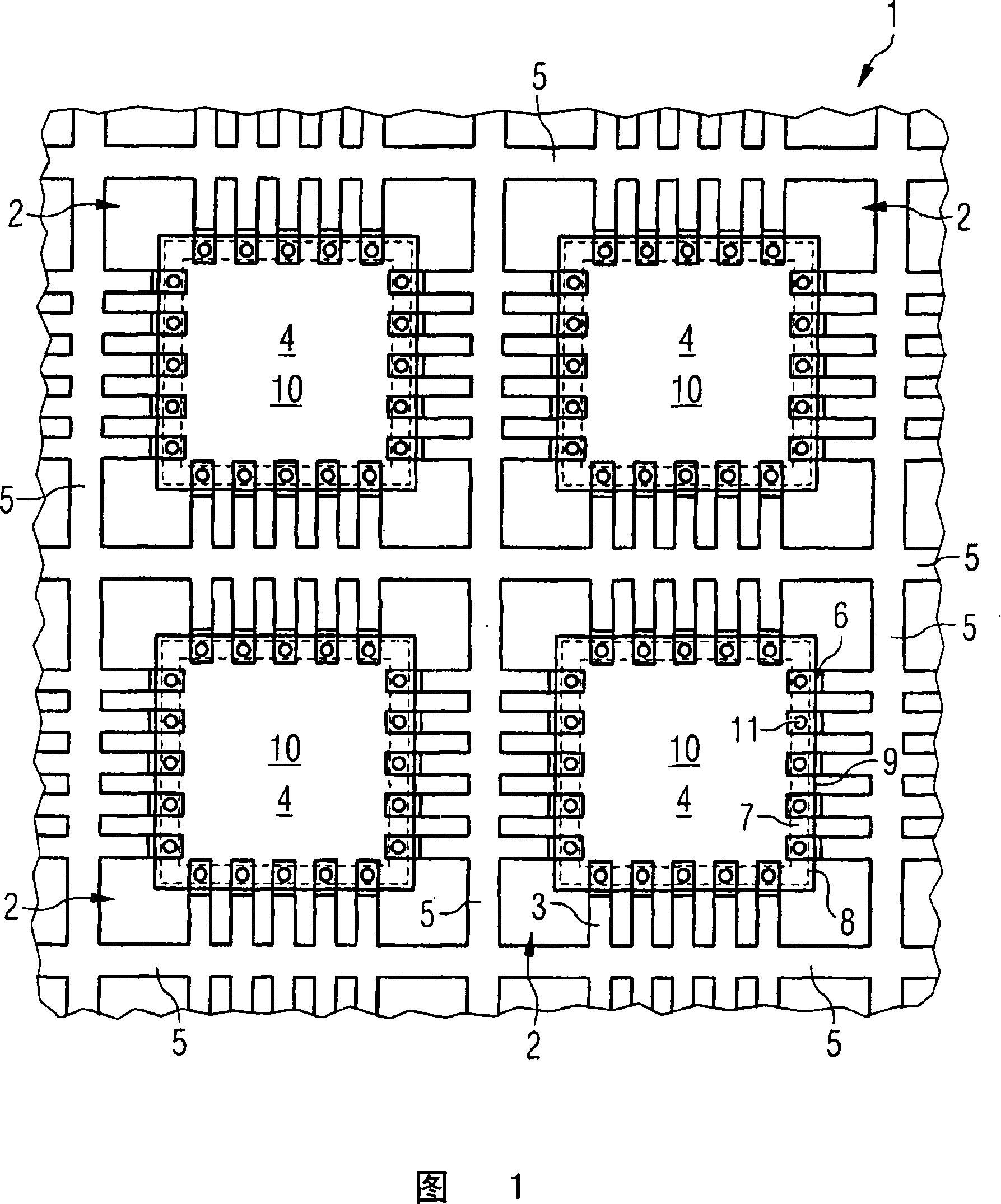

[0086] FIG. 1 shows a top view of a part of a leadframe strip 1 comprising a plurality of packaging locations 2 . Four packaging locations 2 are shown within the section shown in FIG. 1 . Each packaging site 2 is substantially identical and substantially square in the transverse direction. The packaging sites 2 are arranged in rows and columns within the lead frame strip 1 and have a grid configuration.

[0087] Each packaging site 2 comprises a plurality of lead fingers 3 laterally surrounding a chip site 4 . Chip site 4 is approximately in the lateral center of package site 2 . Each packaging location 2 is physically connected to its neighbors by tie rods 5 having a grid configuration.

[0088] Lead fingers 3 protrude inwards from tie bars 5 towards the center of each packaging location 2 . In the example shown in FIG. 1 , each of the four sides of each packaging site 2 includes five lead fingers 3 approximately laterally centrally located on each side. The lead fingers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com