Method for producing device

A device and component technology that is used in semiconductor/solid-state device manufacturing, instruments, electrical components, etc., and can solve problems such as pattern deterioration and the inability of light to reach the top of the substrate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

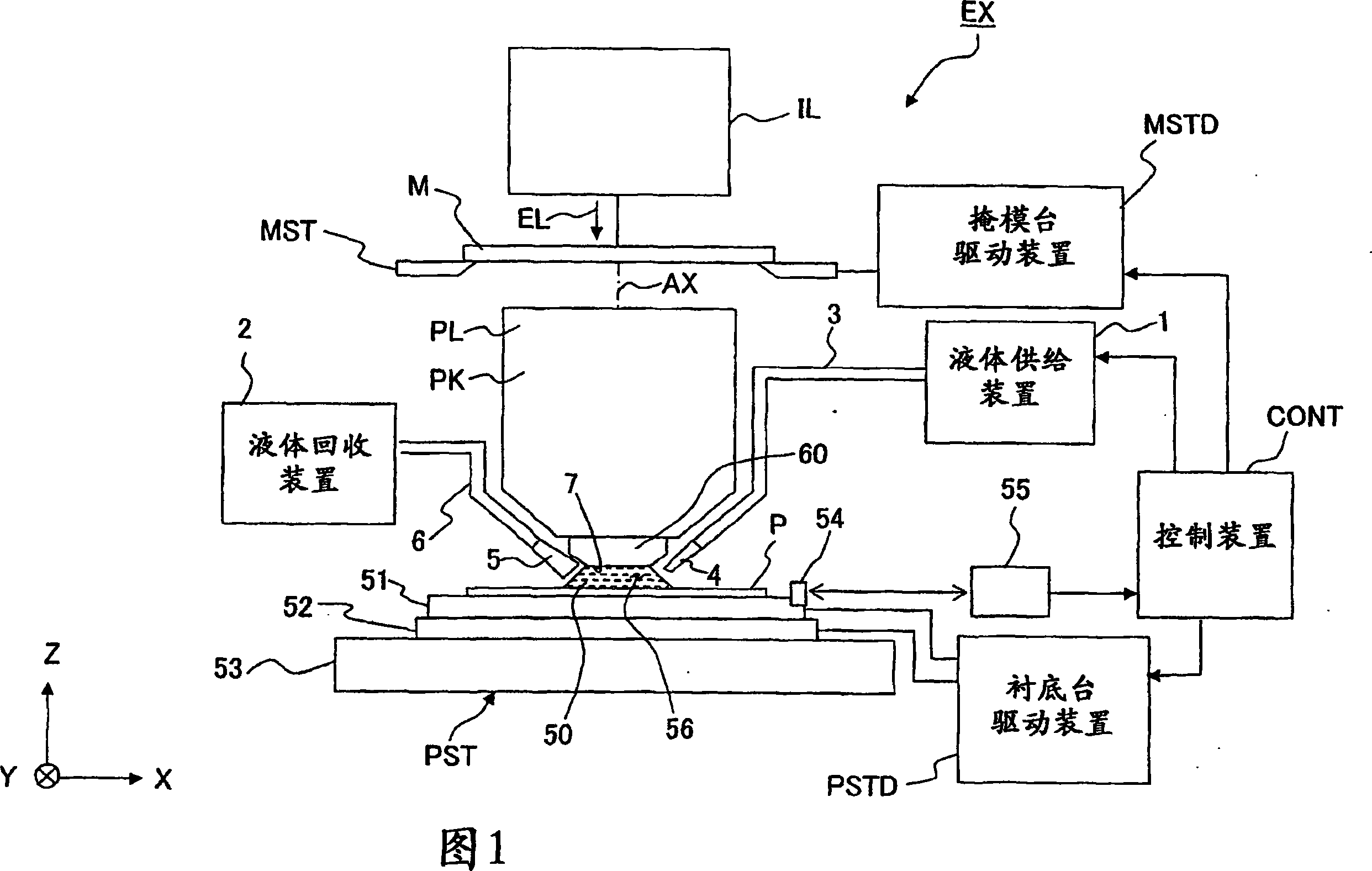

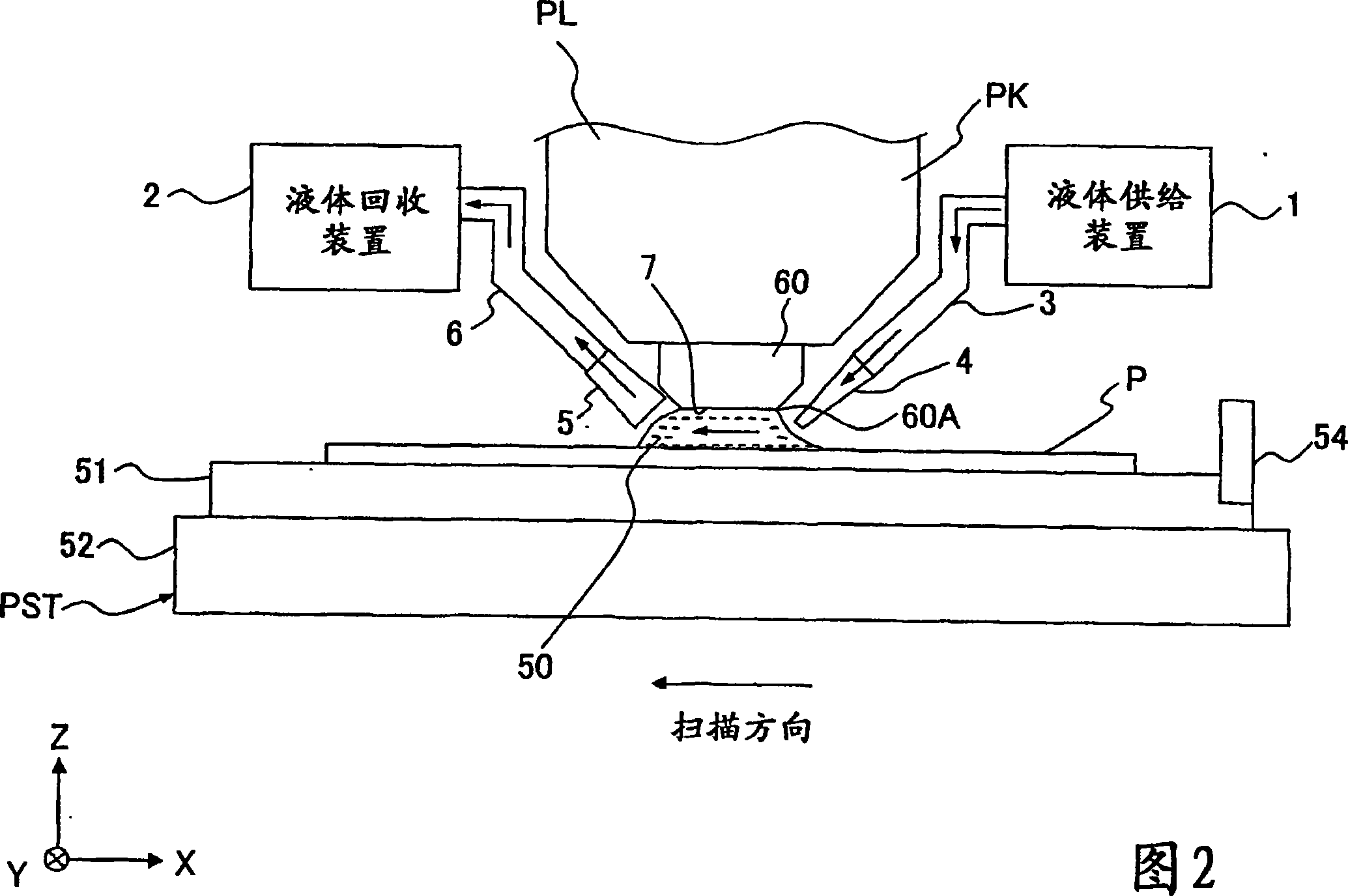

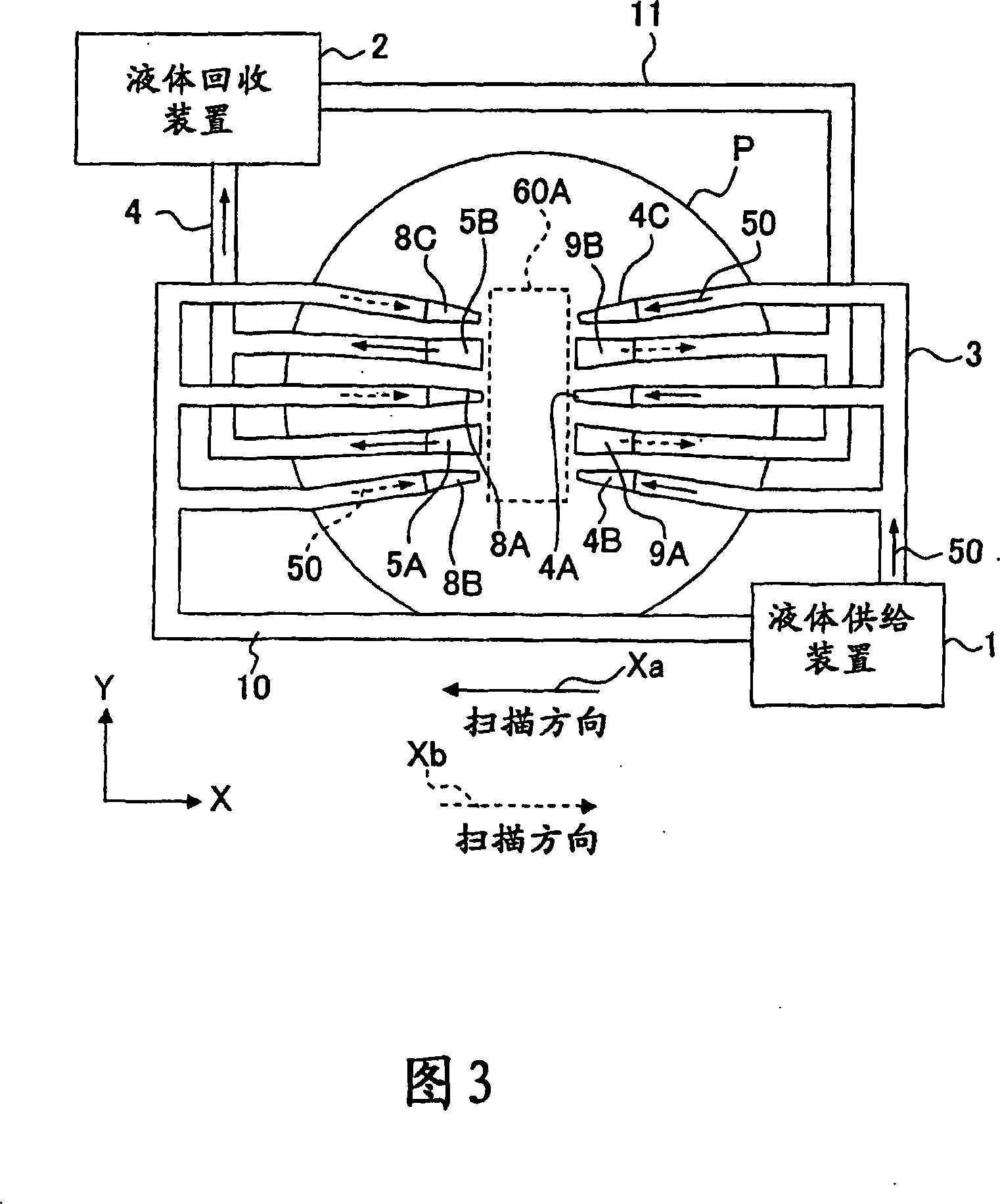

[0039]In FIG. 1 , the exposure apparatus EX includes a mask stage MST for supporting a mask M, a substrate stage PST for supporting a substrate P, and an illumination optical system IL for illuminating the mask M supported by the mask stage MST with exposure light EL. , the projection optical system PL for projecting the pattern image of the mask M illuminated with the exposure light EL onto the substrate P supported by the substrate table PST for exposure, and the control device CONT for overall controlling the overall operation of the exposure apparatus EX.

[0040] Here, for the present embodiment, as an example of the exposure apparatus EX, the mask M and the substrate P are moved synchronously in directions different from each other (opposite directions) to the scanning direction, and the substrate P is exposed and formed on the mask. In the case of a scanning exposure device (so-called scanning stepper) for a pattern on a mold M. In the following description, the directi...

no. 2 Embodiment

[0068] Next, a second embodiment of the exposure apparatus EX of the present invention will be described with reference to FIG. 5 . Here, in the following description, the same or equivalent components as those of the above-mentioned embodiment are given the same reference numerals, and the description thereof will be simplified or omitted. A characteristic part of this embodiment is that a decompression device 23 is provided instead of the heating device 21 .

[0069] As shown in Figure 5, in order to prevent contamination to the substrate P and projection optical system PL, or in order to prevent deterioration of the pattern image projected on the substrate P, the liquid supply device 1 is provided; 50, the filter 20 that removes foreign matter in the liquid 50, the decompression device 23 that degasses the liquid 50 by decompressing the liquid 50 that has removed the foreign matter by the filter 20, and the liquid that has been degassed with the decompression device 23 50 ...

no. 3 Embodiment

[0076] A third embodiment of the exposure apparatus EX of the present invention will be described with reference to FIGS. 6 and 7. FIG. In the exposure apparatus of the present embodiment, a film degassing device 24 and a heating device 25 as shown in FIG. 6 are provided instead of the heating device of the liquid supply device in the first embodiment. In the following description, the same reference numerals are assigned to the same or equivalent components as those of the above-mentioned embodiment, and the description thereof will be simplified or omitted.

[0077] FIG. 6 is a configuration diagram of the liquid supply device 1 . As shown in FIG. 6 , in order to prevent contamination of the substrate P and projection optical system PL, or in order to prevent deterioration of the pattern image projected on the substrate P, the liquid supply device 1 is equipped with: filter the liquid 50 recovered by the liquid recovery device 2, for example. , the filter 20 used to remove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com