Method for preparing TTF-TCNQ nano material

A technology of TTF-TCNQ and nanomaterials, which is applied in the field of preparation of nanomaterials, can solve the problems of no preparation of organic conductor nanomaterials, no method for regulating the morphology of organic conductor nanomaterials, etc., and achieves high yield, simple preparation process, The effect of the simplicity of the separation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

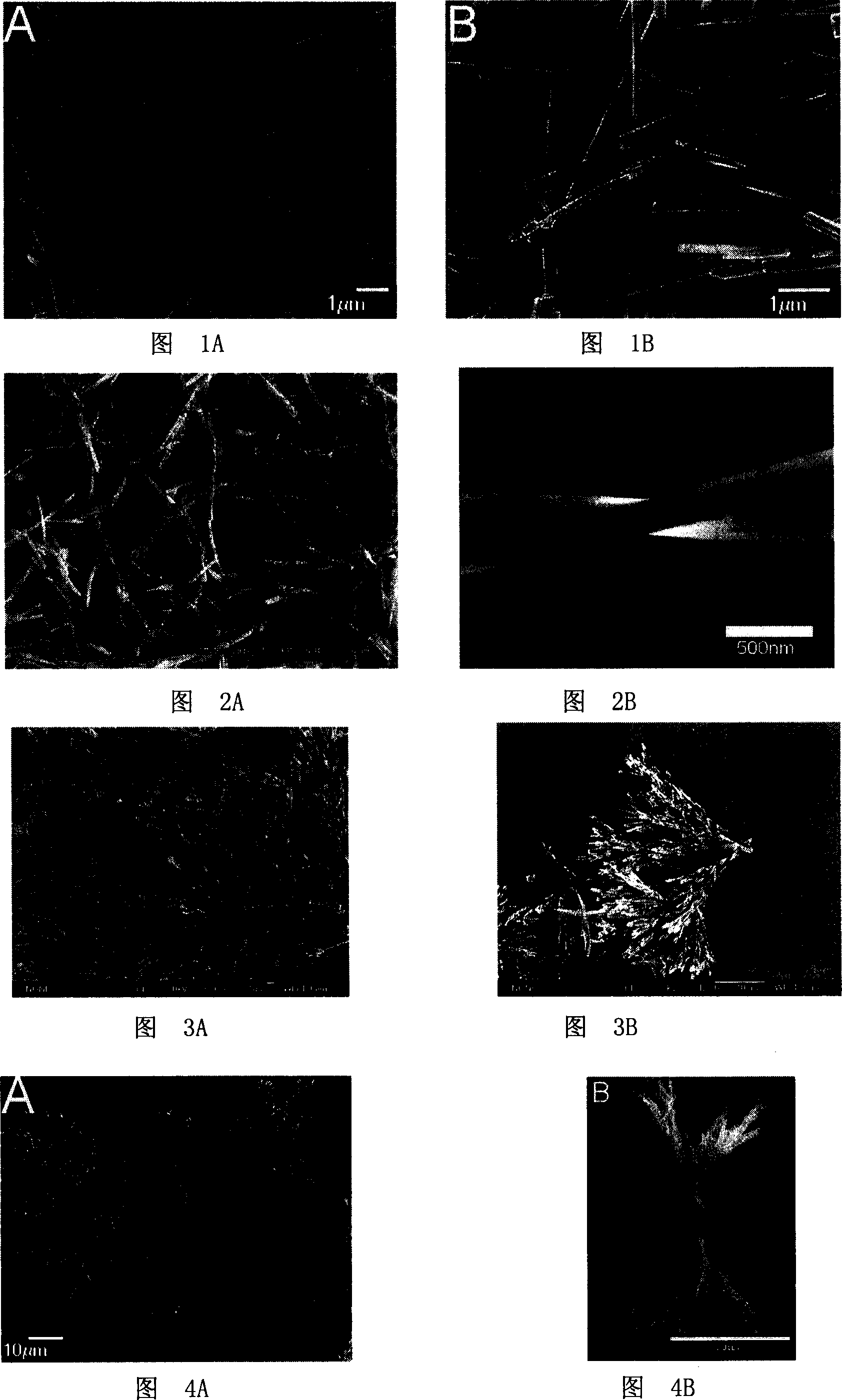

[0018] The preparation of embodiment 1, TTF-TCNQ nanorod

[0019] In a 100mL single-necked flask, add TTF (9.4mg) into 20mL of n-hexane, ultrasonically disperse until completely dissolved, and then stir. TCNQ (13.6 mg) was ultrasonically dissolved completely in 20 mL of acetonitrile, and after being transferred to the capillary dropping funnel, the acetonitrile solution of TCNQ was added to the TTF solution through the capillary dropping funnel, and the rate of addition was controlled to be 1 μL / s (microliter / s seconds), after the completion of the reaction, a black solid was obtained at the bottom of the single-necked flask, and the solid was centrifuged, washed twice with n-hexane, and dried at room temperature for 2 hours to obtain a black powder, with a yield of 95%.

[0020] Disperse 0.1mg of TTF-TCNQ sample in 2mL of ethanol, then take a drop and drop it on the silicon, spray gold and stick it on the sample stage with conductive adhesive for scanning electron microscope ...

Embodiment 2

[0021] Embodiment 2, the preparation of TTF-TCNQ nanowire

[0022] In a 100mL single-necked flask, add TTF (9.4mg) into 20mL of n-hexane, ultrasonically disperse until completely dissolved, and then stir. TCNQ (13.6 mg) was ultrasonically dissolved completely in 20 mL of acetonitrile, and after being transferred to the capillary dropping funnel, the acetonitrile solution of TCNQ was added to the TTF solution through the capillary dropping funnel, and the rate of addition was controlled to be 20 μL / s (microliter / s seconds), after the completion of the reaction, a black solid was obtained at the bottom of the single-necked flask, and the solid was centrifuged, washed twice with n-hexane, and dried at room temperature for 2 hours to obtain a black powder, with a yield of 95%.

[0023] Disperse 0.1mg of TTF-TCNQ sample in 2mL of ethanol, then take a drop and drop it on the silicon, spray gold and stick it on the sample stage with conductive adhesive for scanning electron microscop...

Embodiment 3

[0024] Embodiment 3, the preparation of TTF-TCNQ helix

[0025] In a 100mL single-necked flask, add TTF (9.4mg) into 20mL of n-hexane, ultrasonically disperse until completely dissolved, and then stir. TCNQ (13.6mg) was ultrasonically dissolved completely in 20mL of acetonitrile, and after being transferred to the capillary dropping funnel, the acetonitrile solution of TCNQ was added to the TTF solution through the capillary dropping funnel, and the dropping rate was controlled to be 40 μL / s (microliter / s seconds), after the completion of the reaction, a black solid was obtained at the bottom of the single-necked flask, and the solid was centrifuged, washed twice with n-hexane, and dried at room temperature for 2 hours to obtain a black powder, with a yield of 95%.

[0026] Disperse 0.1mg of TTF-TCNQ sample in 2mL of ethanol, then take a drop and drop it on the silicon, spray gold and stick it on the sample stage with conductive adhesive for scanning electron microscope (SEM) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com