Low noise thin type photoelectric sensor and manufacturing method therefor

A photoelectric sensing, low-noise technology, used in radiation control devices, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of scratching the optical conversion area, destroying the photoelectric sensing device, and poor storage environment of the photoelectric sensing device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] In order to have a further understanding and understanding of the features, structures, methods and achieved effects of the present invention, the following preferred embodiments and detailed descriptions in conjunction with the present invention are described as follows.

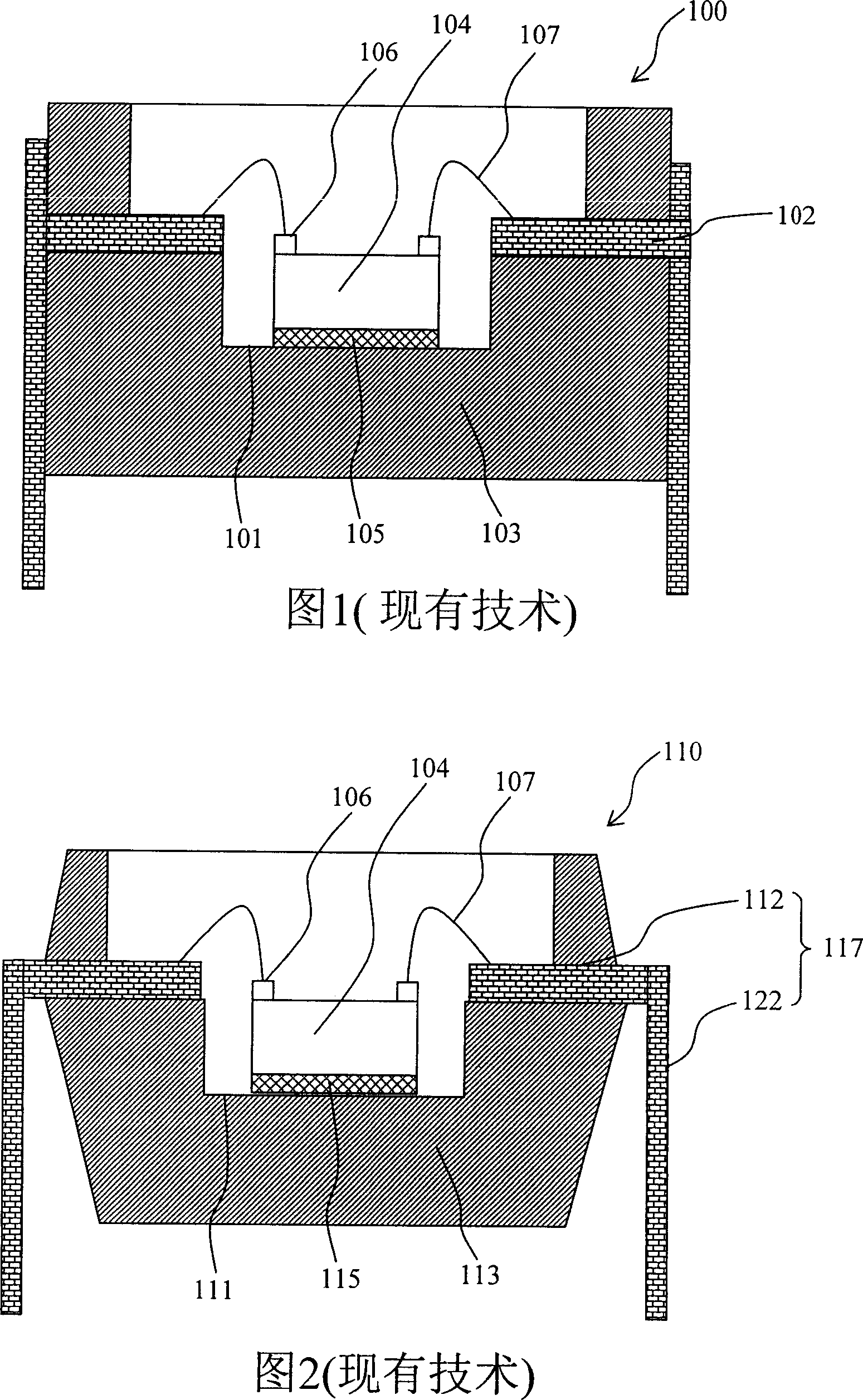

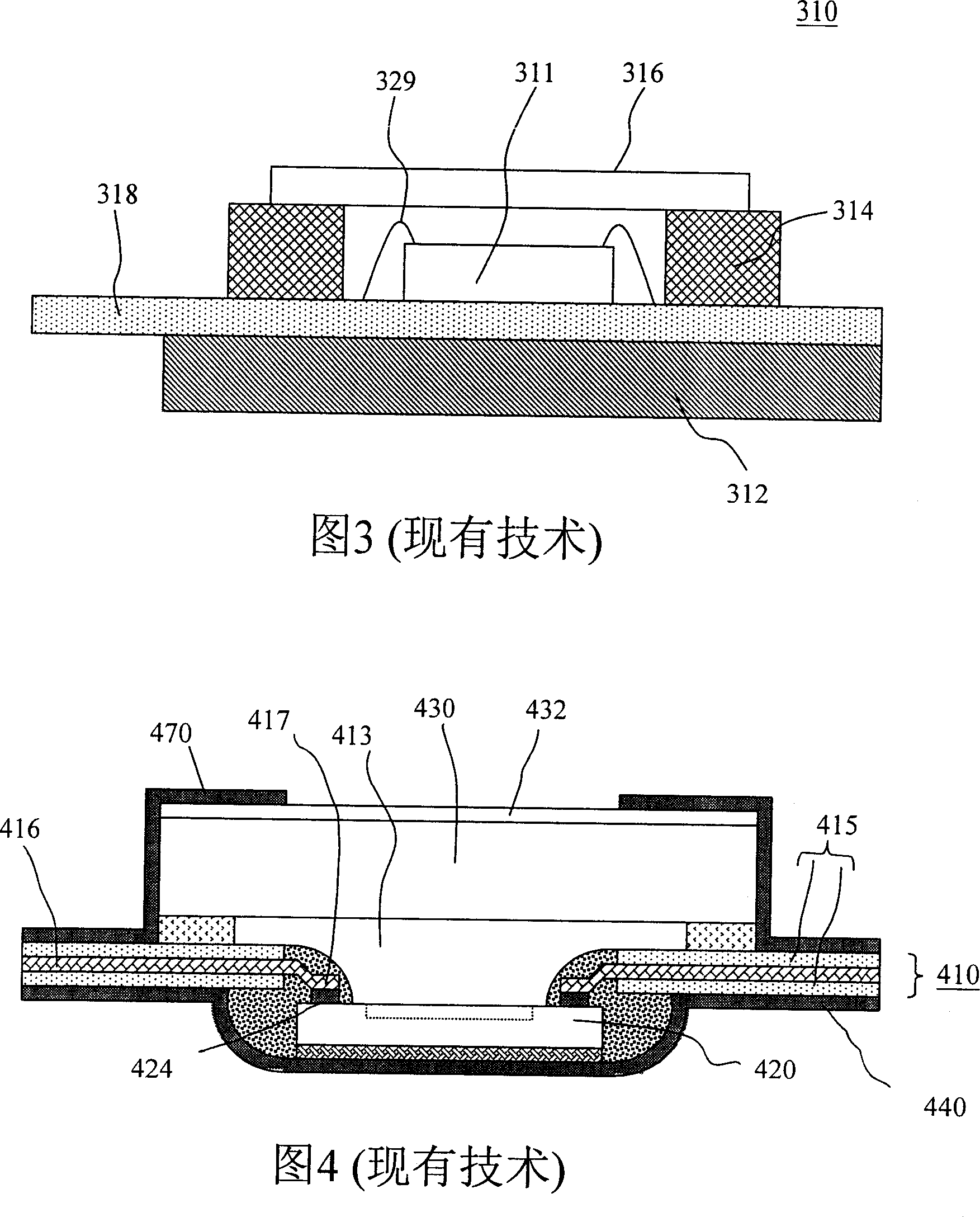

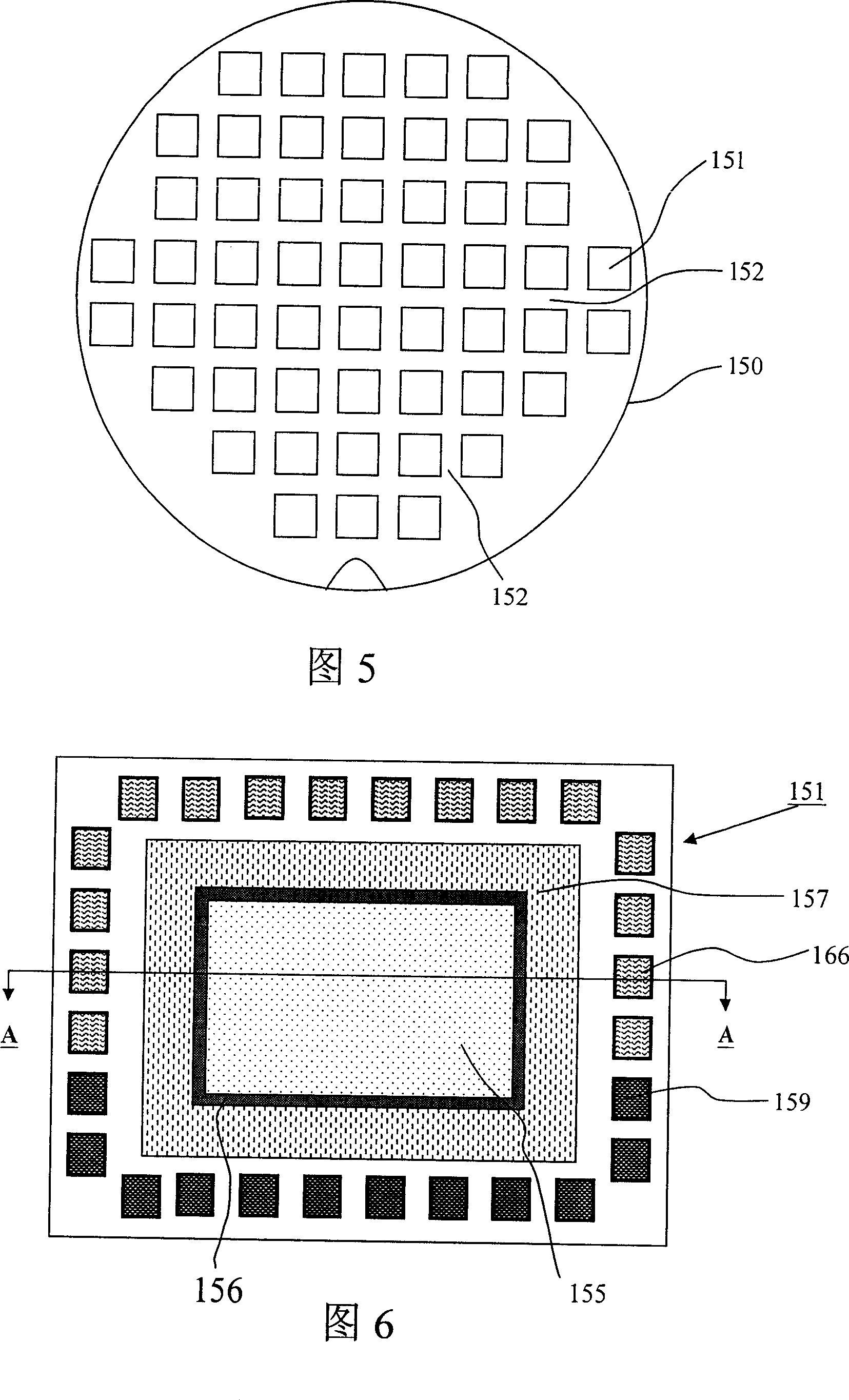

[0095]A photoelectric sensing device according to an embodiment of the present invention includes a photoelectric sensing substrate containing a photoelectric element conversion region and a transparent substrate provided with at least one groove, which are directly bonded to each other by bonding technology, and the concave substrate of the transparent substrate is The groove is an electrode pad corresponding to the photoelectric sensing substrate. In addition, the external electrical connection end of the photoelectric sensing device can be thinned from the upper surface of the transparent substrate to the bottom of the groove, so that the electrode pads inside are exposed or through another connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com