Torsion beam suspension

A technology of torsion beam type suspension and torsion beam, which is applied to suspensions, elastic suspensions, cantilevers mounted on pivots, etc., can solve the problem of narrow freedom in selecting the arrangement position of the threaded hole, increased processes, etc. Cost increase and other problems, to achieve the effect of improving rigidity, suppressing seat surface deformation, and eliminating thermal strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

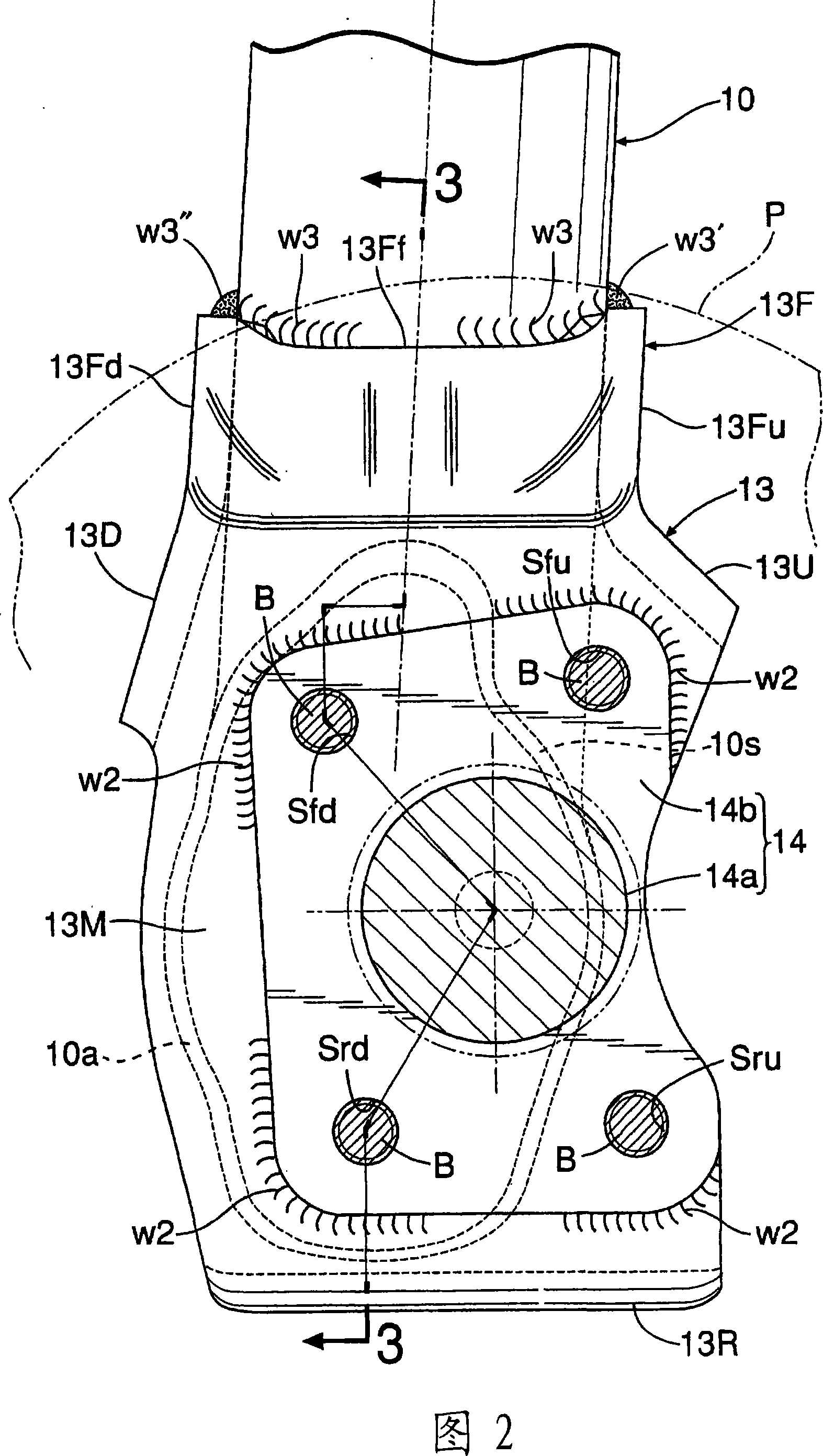

[0078] 1 to 5 show a first embodiment of the present invention.

[0079] First, FIG. 1 is a top view of the left half of the torsion beam suspension for the rear wheels of an automobile, and the right half has a left-right symmetrical structure with respect to the front and rear centerlines of the vehicle body. This torsion beam type suspension has: a pair of left and right trailing arms 10 extending substantially linearly in the substantially front-rear direction of the vehicle body; The torsion beam 11 is welded between the end of the torsion beam 11 and the middle of the trailing arm 10 to increase the bonding strength between them.

[0080] A cylindrical trailing arm support part 12 is welded on the front end of each trailing arm 10, and the trailing arm support part 12 passes through a rubber bush joint (not shown) accommodated in the trailing arm support part 12. It is pivotally supported on the vehicle body to swing freely up and down. The rear wheel W is freely rotat...

Embodiment 2

[0105] Next, a second embodiment of the present invention will be described with reference to FIGS. 8 to 12 . Since the basic structure of the torsion beam suspension in this second embodiment is the same as that in the first embodiment, the reference numbers of the corresponding components in the first embodiment are changed to 100 and assigned to the second embodiment Each constituent element of the basic structure, the description of the basic structure is omitted. Hereinafter, the parts different from those of the first embodiment will be mainly described.

[0106] The spindle support plate 113 has a substantially square-shaped plate main body 113M whose back surface is butted against the opening end surface 110 a at the rear end of the trailing arm 110 and welded w11 . The surface (the left side in FIG. 10 ) of the plate main body 113M is a flat mounting seat surface with respect to the main shaft 114, and on the back side of the main plate main body, the main shaft axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com