Casing tube boiler

A casing boiler and inner tube technology, which is applied in steam boilers, firebox-type steam boilers, fluid heaters, etc., can solve the problems of long production time of hot water or steam, small heat exchange area, and large water consumption. Achieve fuel saving, large heat exchange area, and less water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

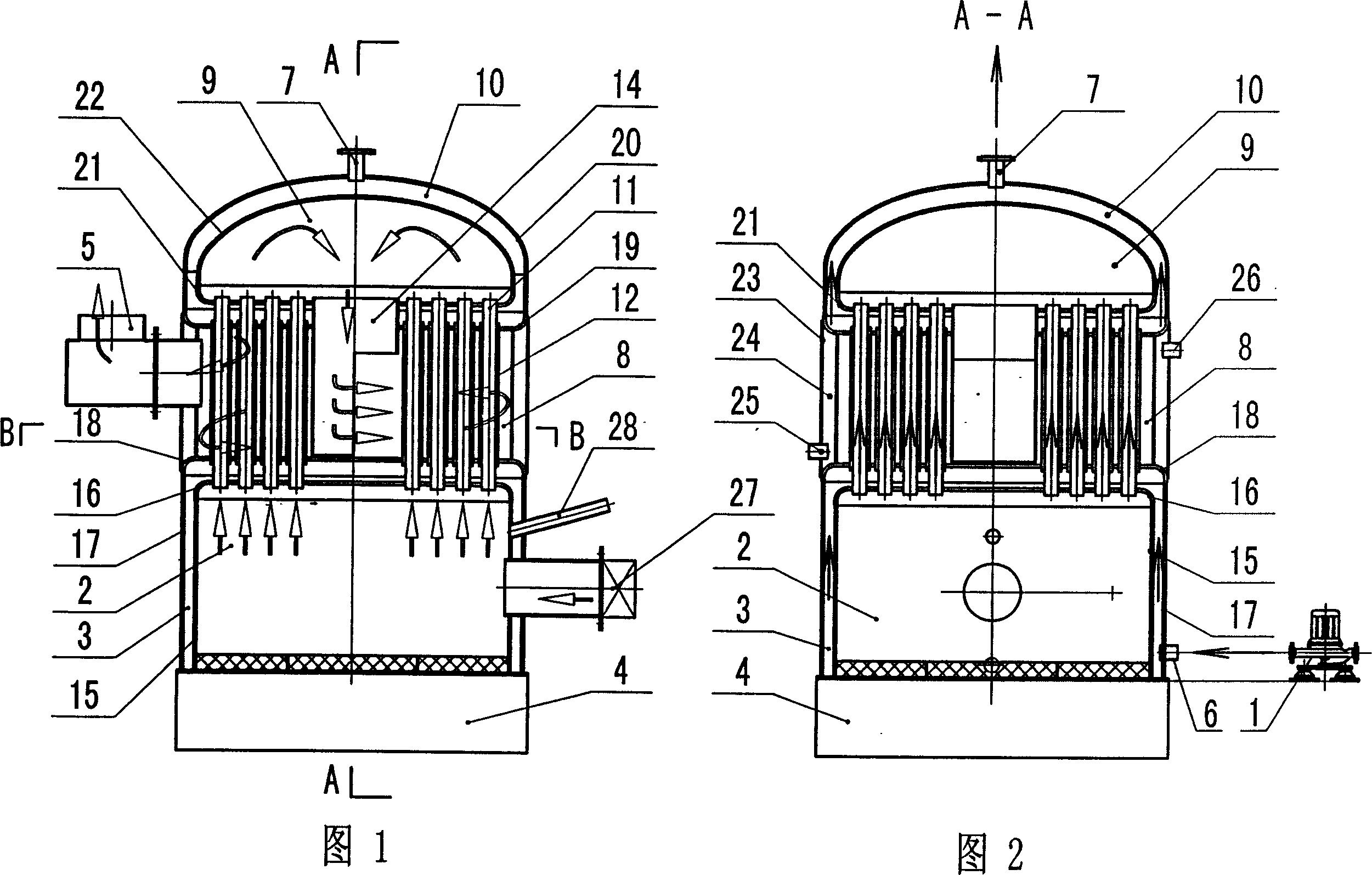

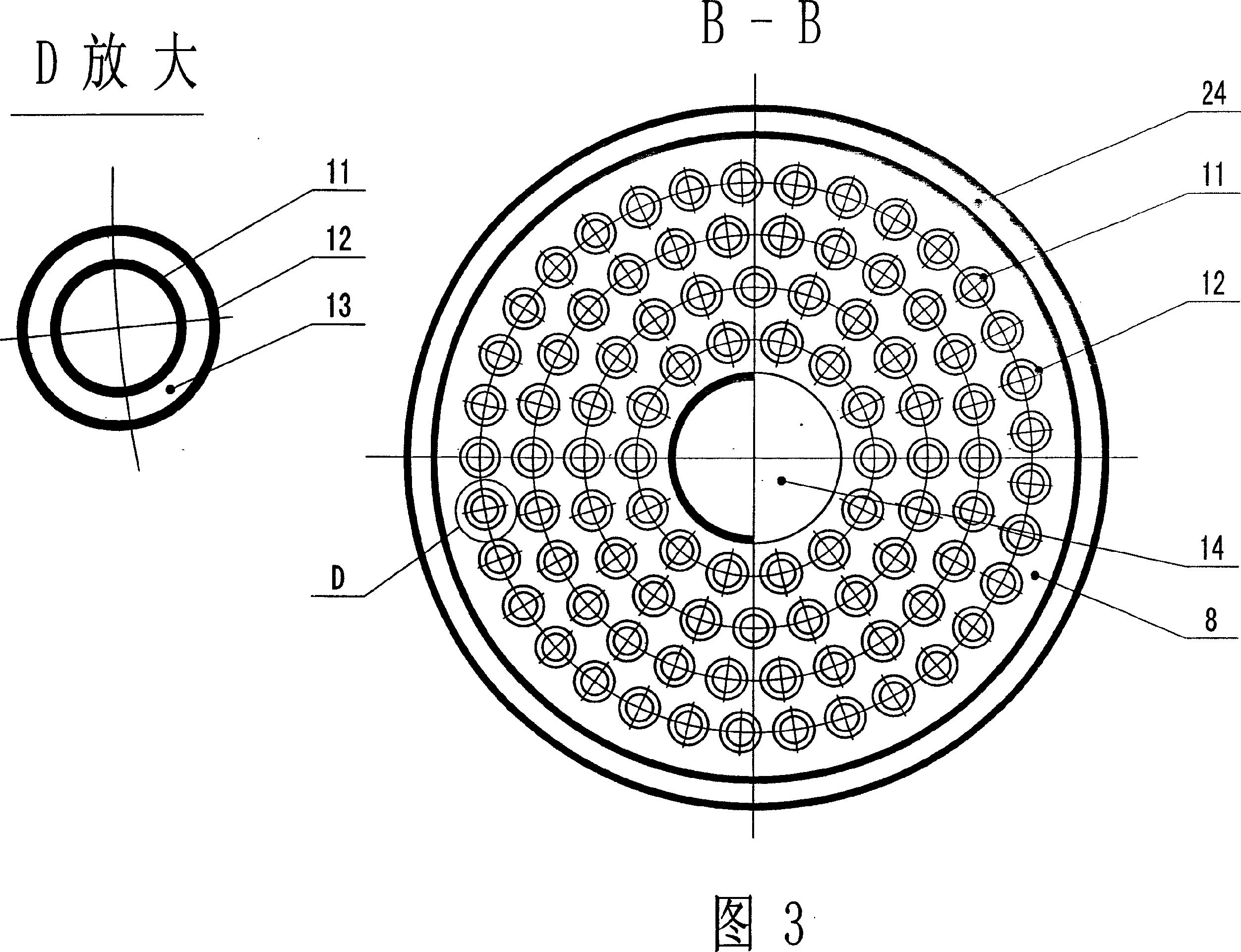

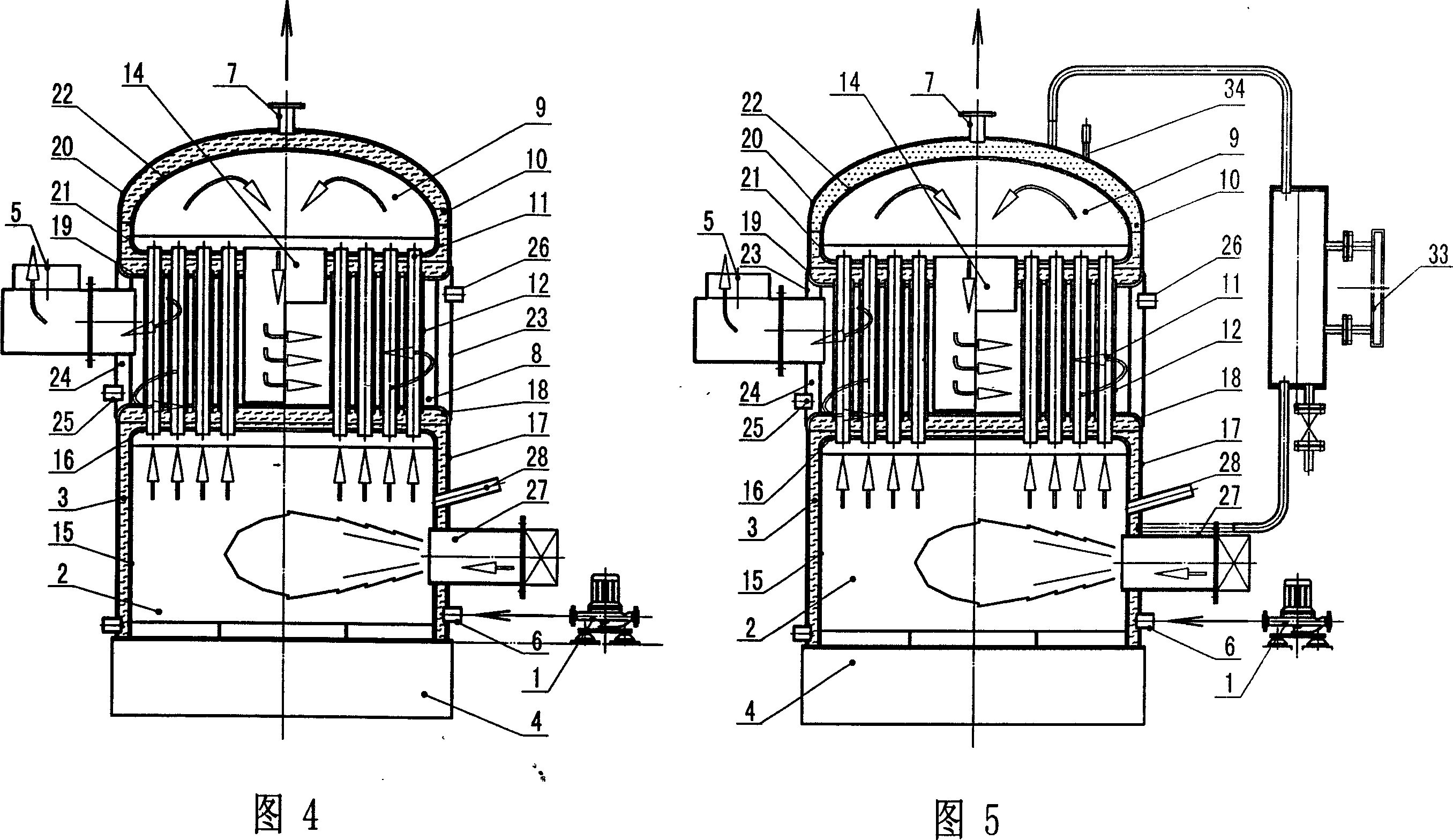

[0023] Embodiment 1 is a fuel-fired and gas-fired hot water casing boiler, as shown in Figure 4: a burner 27 and a fire port 28 are provided on one side of the combustion chamber 2 of the casing boiler; a hot water outlet 7 is provided on the top.

Embodiment 2

[0024] Embodiment 2 is an oil-fired, gas-fired steam casing boiler, as shown in Figure 5: on one side of the combustion chamber 2 of the above-mentioned casing boiler, a burner 27 and a flame viewing port 28 are arranged; a pressure gauge 34 and a steam outlet 7 are arranged on the top thereof , and set a water level gauge 33 on one side of the furnace body

Embodiment 3

[0025] Embodiment 3 is a solid fuel hot water casing boiler, as shown in Figure 6: on one side of the casing boiler combustion chamber 2, a feed inlet 29, a furnace door 30, a grate 31, and a soot cleaning port are arranged at the bottom 32, its top is provided with hot water outlet 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com