Double group component sydraulic free-piston engine

A piston engine and two-component technology, applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc., can solve the problems of strict compression ratio and compression stroke, separate ignition system, etc., and achieve high system reliability and simple structure , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

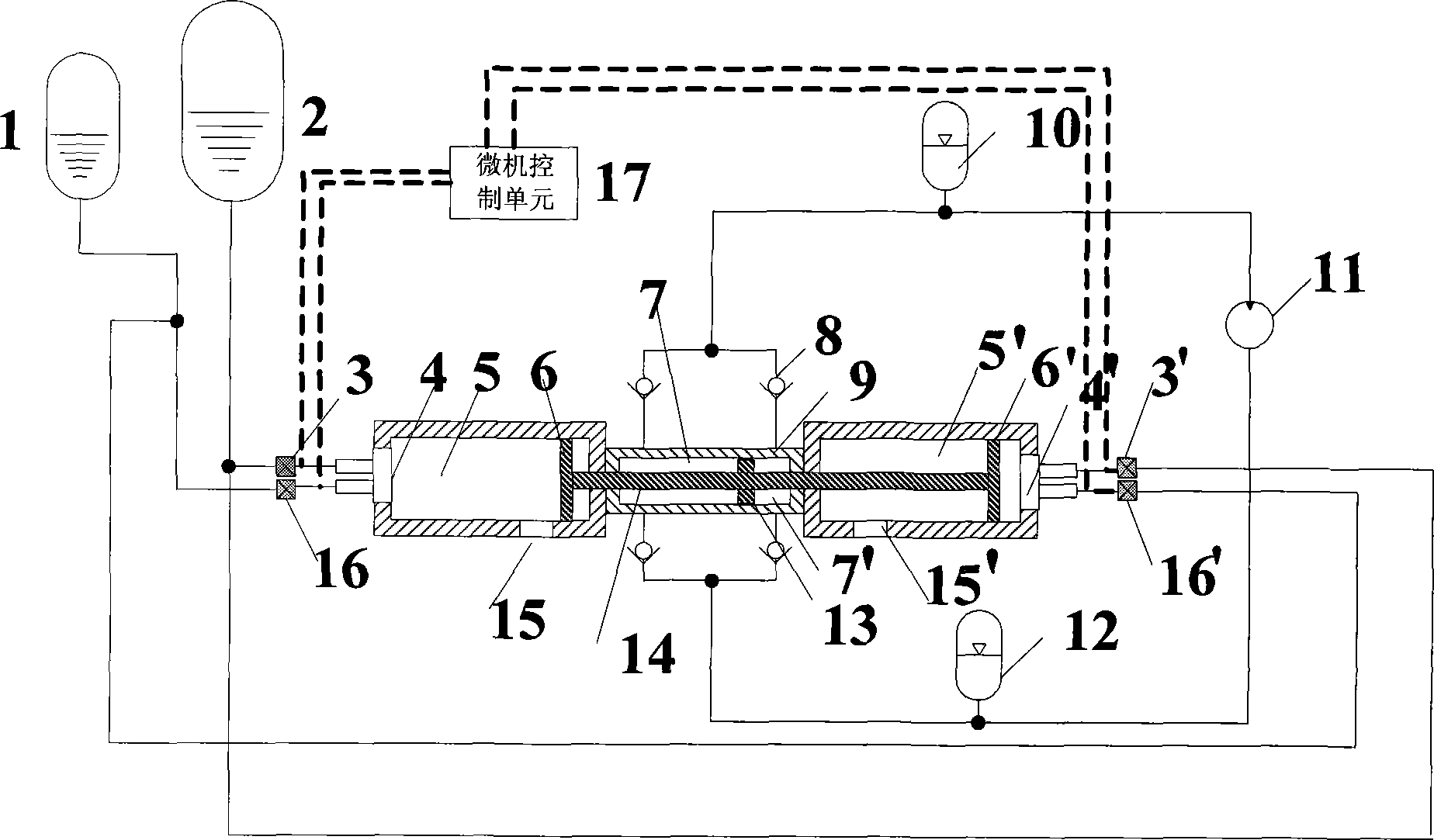

[0012] As shown in the drawings, the present invention includes that the first cylinder 5 is connected with the second cylinder 5' through the hydraulic pump cavity 7, and connects the first power piston 6 at one end of the piston rod 14, the pump piston 13 in the middle and the second cylinder at the other end. The power piston 6' is installed in the first cylinder 5, the hydraulic pump chamber 7 and the second cylinder 5' respectively. The pump piston 13 is connected with a distribution check valve group 8, and one end of the distribution check valve group 8 is stored by high pressure. The device 10 is connected to one end of the load 11, and the other end of the distribution check valve group 8 is connected to the other end of the load 11 through the low pressure accumulator 12. The outlet of the oxidant tank 1 is divided into two paths, one path is connected to the air inlet 4 of the first cylinder 5 through the first oxidant control valve 16, and the other path is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com