Technique for film plating on powder surface and equipment thereof

A powder and equipment technology, applied in the field of vacuum coating process and its equipment, can solve the problems of increasing manufacturing cost, complicated equipment structure, increasing equipment operating cost, etc., and achieve the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

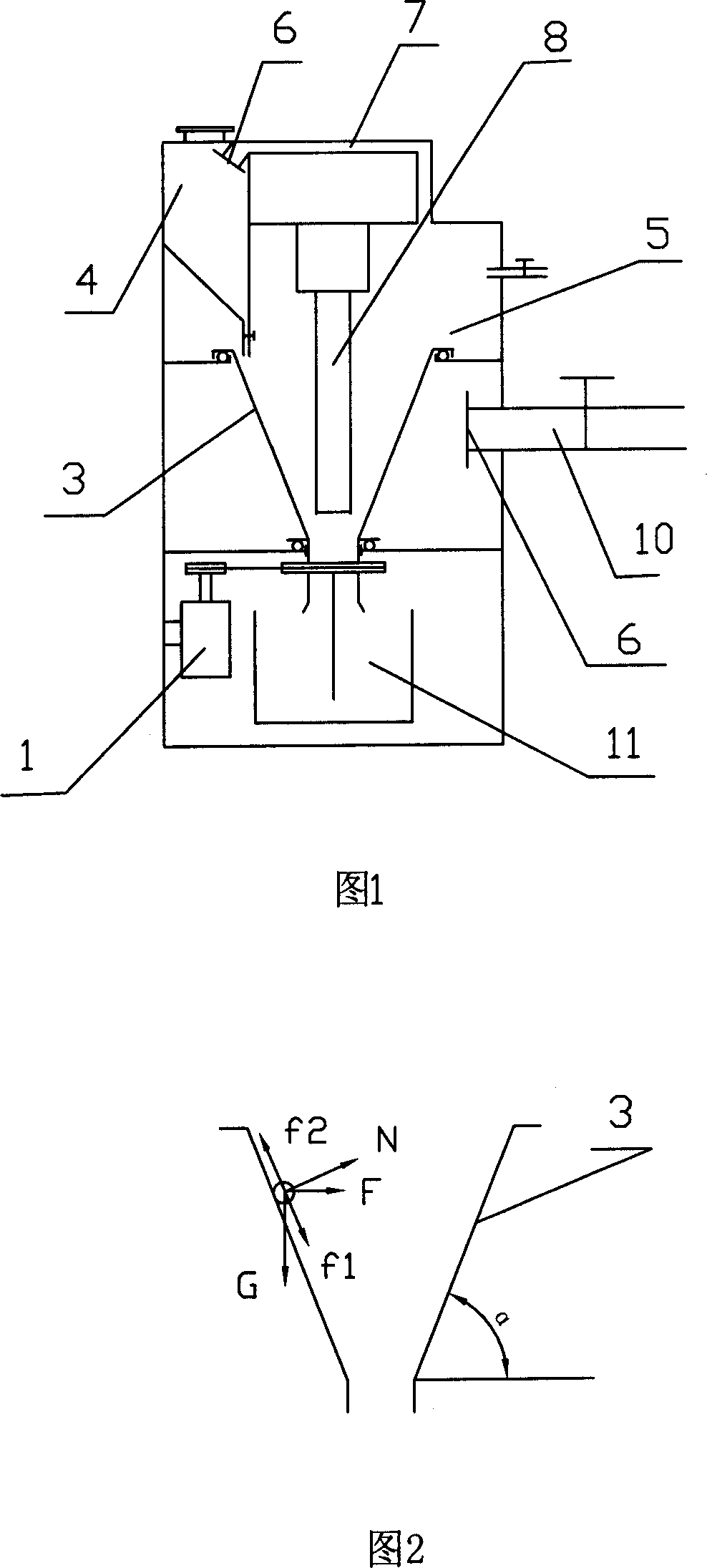

[0027] The present invention is a process for coating the surface of powder, which mainly includes:

[0028] (1) provide a vacuum environment;

[0029] (2) Let the powder fall in a vacuum environment, and in the process of falling, use a vacuum coating source to coat the surface of the powder;

[0030] (3) The powder performs a spiral motion during the falling process in the above-mentioned vacuum environment, and at the same time, it also turns over, so that a relatively uniform coating is formed on the surface of the powder;

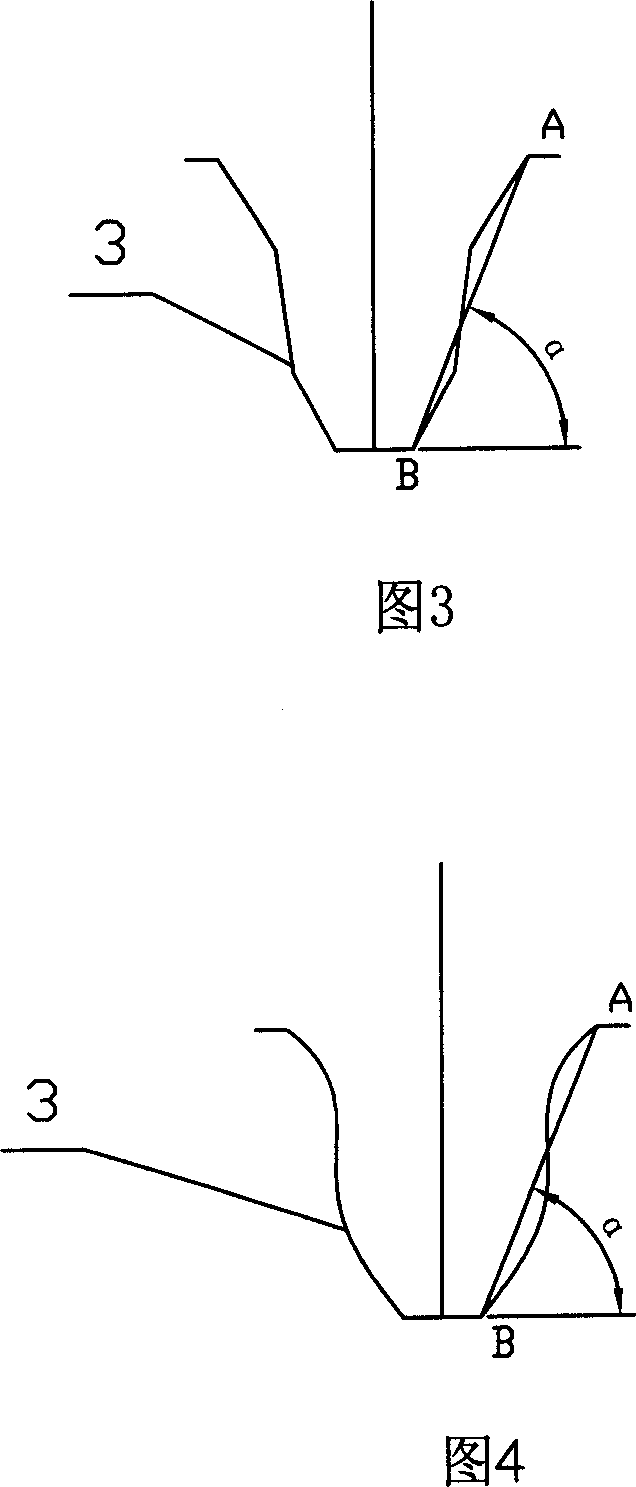

[0031] (4) The above-mentioned vacuum environment is provided with a rotating inverted cone hopper. The vacuum coating source is located in the center of the inverted cone hopper. The powder falls along the wall of the rotating inverted cone hopper. The rotating inverted cone The rotation speed of the type hopper is controlled by the drive motor, which in turn controls the coating thickness obtained on the powder surface.

[0032] The present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com