Multi-layer moisture making compound film for proton exchange film fuel cell and its making method

A proton exchange membrane and fuel cell technology, applied in fuel cell parts, solid electrolyte fuel cells, fuel cells, etc., can solve the problem of low glass transition temperature of perfluorosulfonic acid resin, increased battery contact resistance, and low mechanical stability and other problems, to achieve the effect of improving self-humidification effect, good stability and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

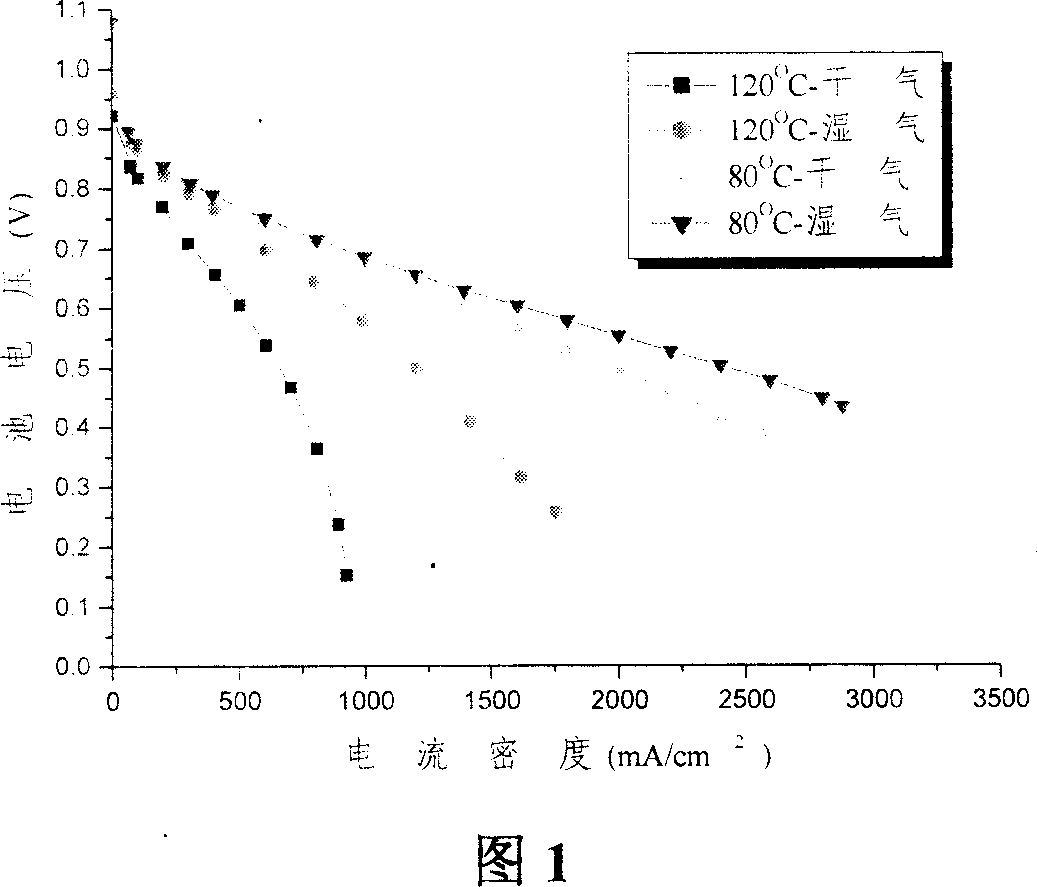

[0038] Weigh 0.3 g of sulfonated polybiphenyl ether sulfone (SPSU), and dissolve it with 6 g of DMAC. Take a porous PTFE (thickness 10 μm, pore diameter 0.3-0.5um, porosity 85%) membrane, soak and clean it with absolute ethanol at 80°C, and then tighten it on a stainless steel cast membrane frame (10×11cm 2 ), the SPSU / DMAC solution was poured on the PTFE porous membrane, heated on a hot stage at 60°C for 3 hours, and then heated in a vacuum oven at 120°C for 12 hours. After taking it out, soak it in deionized water to separate the membrane, then take off the composite membrane to obtain a SPSU / PTFE composite membrane with a thickness of 25 μm. Take two portions of 1.0g 5wt.% Nafion Solution, volatilize the solvent on a heating platform at 60°C to form a transparent resin, then dissolve it with 0.5g isopropanol, and add 2.3mPt / SiO 2 (2wt.% Pt) catalyst, after ultrasonically dispersing the resulting solution for 30 minutes, two parts of Pt / SiO 2 / Nafion The solution was...

Embodiment 2

[0044] Weigh 0.6g sulfonated polybiphenyl ether sulfone (SPSU), dissolve it with 12g DMAC, add 30mgPt / SiO 2 (2 wt.% Pt) catalyst, and the resulting solution was ultrasonically dispersed for 30 minutes. Take a porous PTFE (thickness 10 μm, pore diameter 0.3-0.5um, porosity 85%) membrane, soak and clean it with absolute ethanol at 80°C, and then tighten it on a stainless steel cast membrane frame (10×11cm 2 ) on the Pt-SiO 2 / SPSU / DMAC solution is poured on the porous PTFE membrane, heated on a hot stage at 60°C for 3 hours, then heated in a vacuum oven at 120°C for 12 hours, after taking it out, soak it in deionized water to separate the membrane and remove the composite membrane to obtain Pt-SiO with a thickness of 50 μm 2 / SPSU / PTFE composite membrane, the catalyst load is 0.0055mgPt / cm 2 .

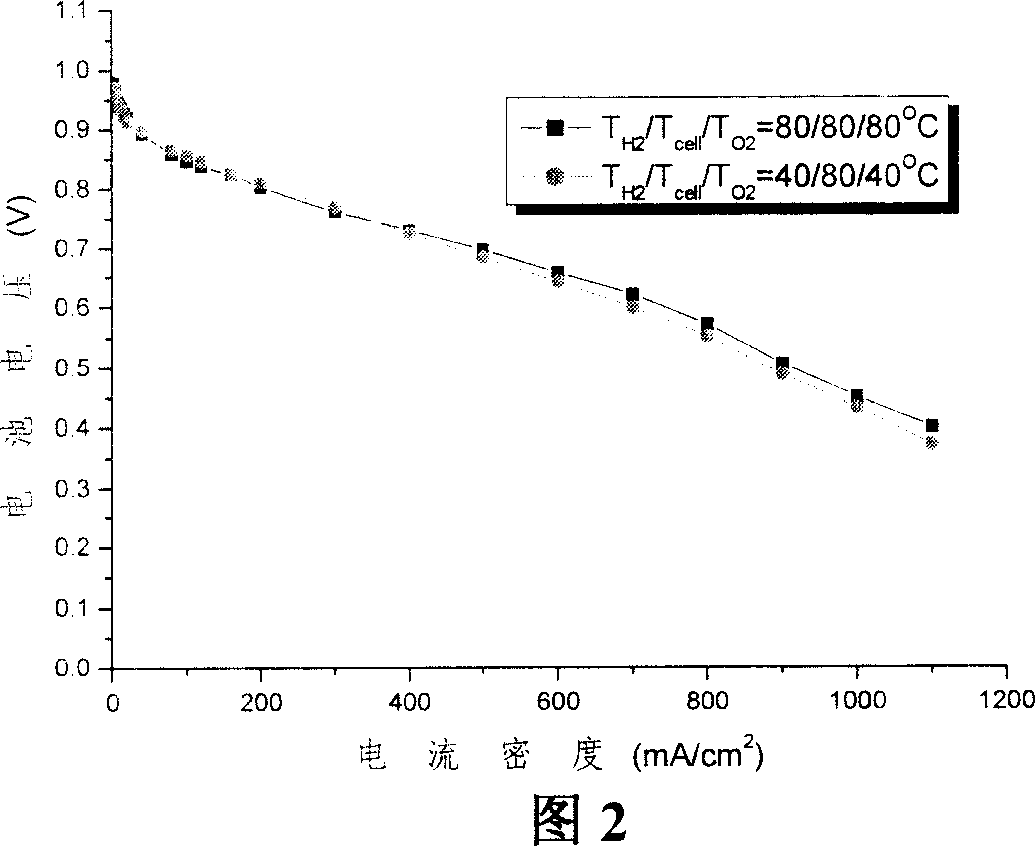

[0045] The method of assembling the PEMFC and the experimental conditions of battery performance are the same as those in Example 1, and the battery performance is shown in Figure 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com