Plastic-lining centrifugal pump special-shaped flow passage processing device

A processing device and centrifugal pump technology, which is applied to parts of pumping devices for elastic fluids, metal processing equipment, pumps, etc., can solve the problems of poor hydraulic characteristics, low work efficiency, low pump efficiency, etc. Simple structure and the effect of saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

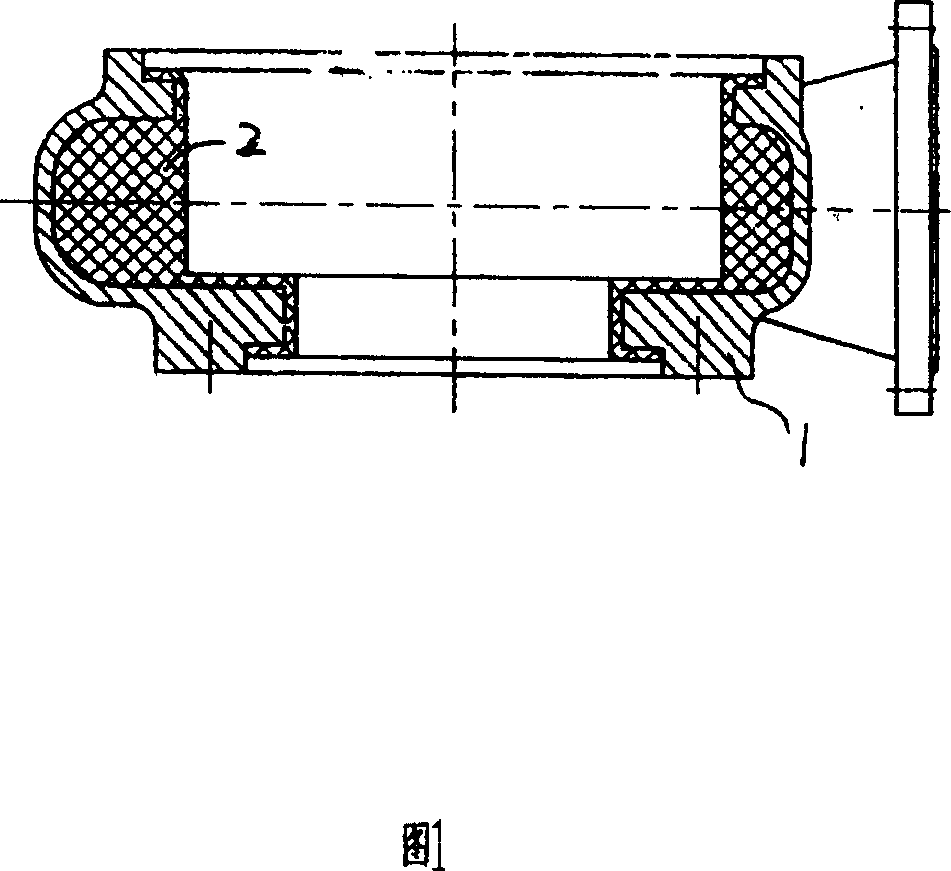

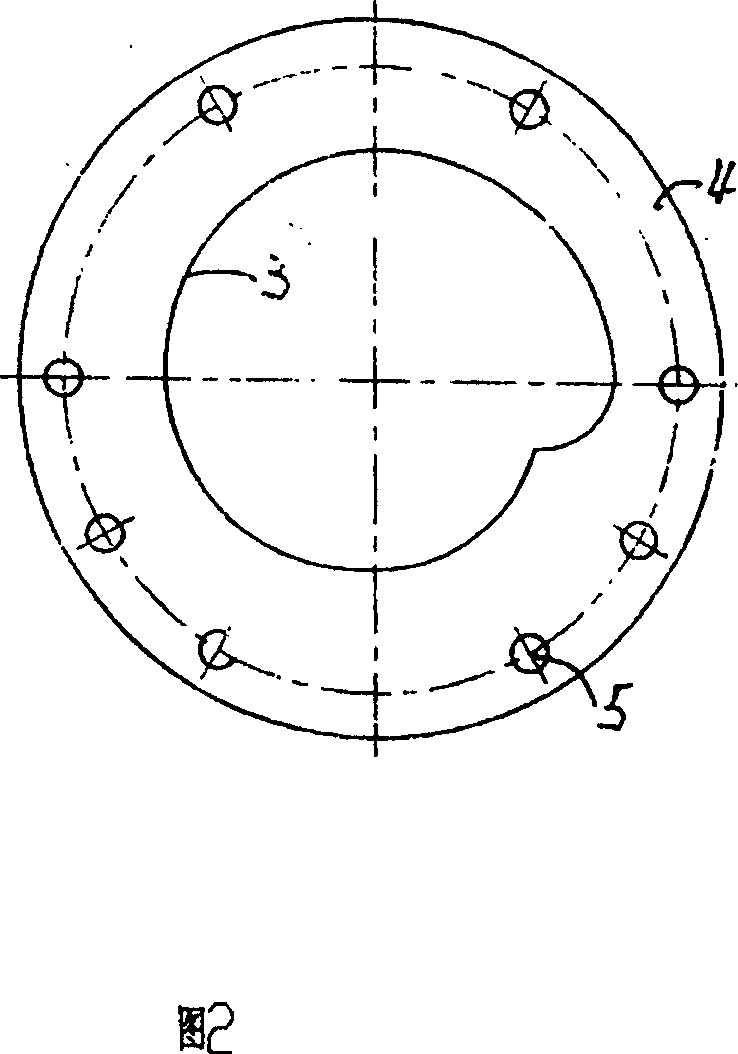

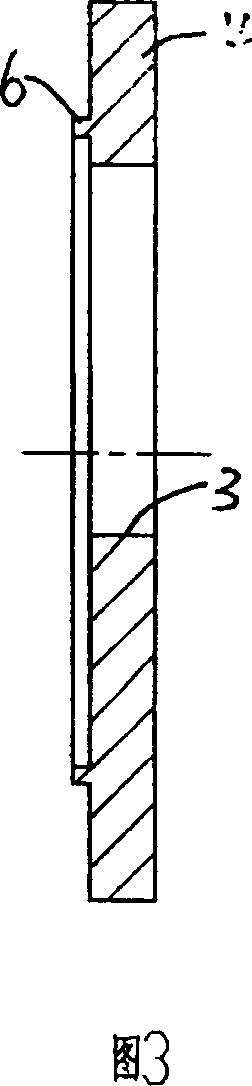

[0015] Embodiment: Referring to the accompanying drawings, the metal volute 1 of an involute centrifugal pump is used as the outer mold, and a circular or approximately circular flow path with a certain thickness is obtained as a lining by a molding method. Ultra-high molecular weight polyethylene or polypropylene lining plastic layer 2 (Figure 1). Then, the milling template 4 ( FIG. 2 ) with the volute flow channel 3 matched with the front pump cover is fixed on the front pump cover side of the metal pump body 1 ( FIG. 7 ) through the fixing screw hole 5 . In order to facilitate accurate positioning, the inside of the milling template is provided with a positioning convex ring 6 (Fig. 3). Bearing 7 (Fig. 4) is provided in the positioning sleeve at the location of the milling mold runner track corresponding to the tool handle 8 of the milling cutter 9 having the same width as the runner. During the cutting process, the bearing on the milling tool shank is attached to the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com