Rotor blade for wind power equipment

A technology for wind power generation equipment and rotor blades, which is applied in wind power generator components, wind power engine monitoring, wind power generation, etc., and can solve the problems of inability to achieve direct comparability between airflow conditions and icing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

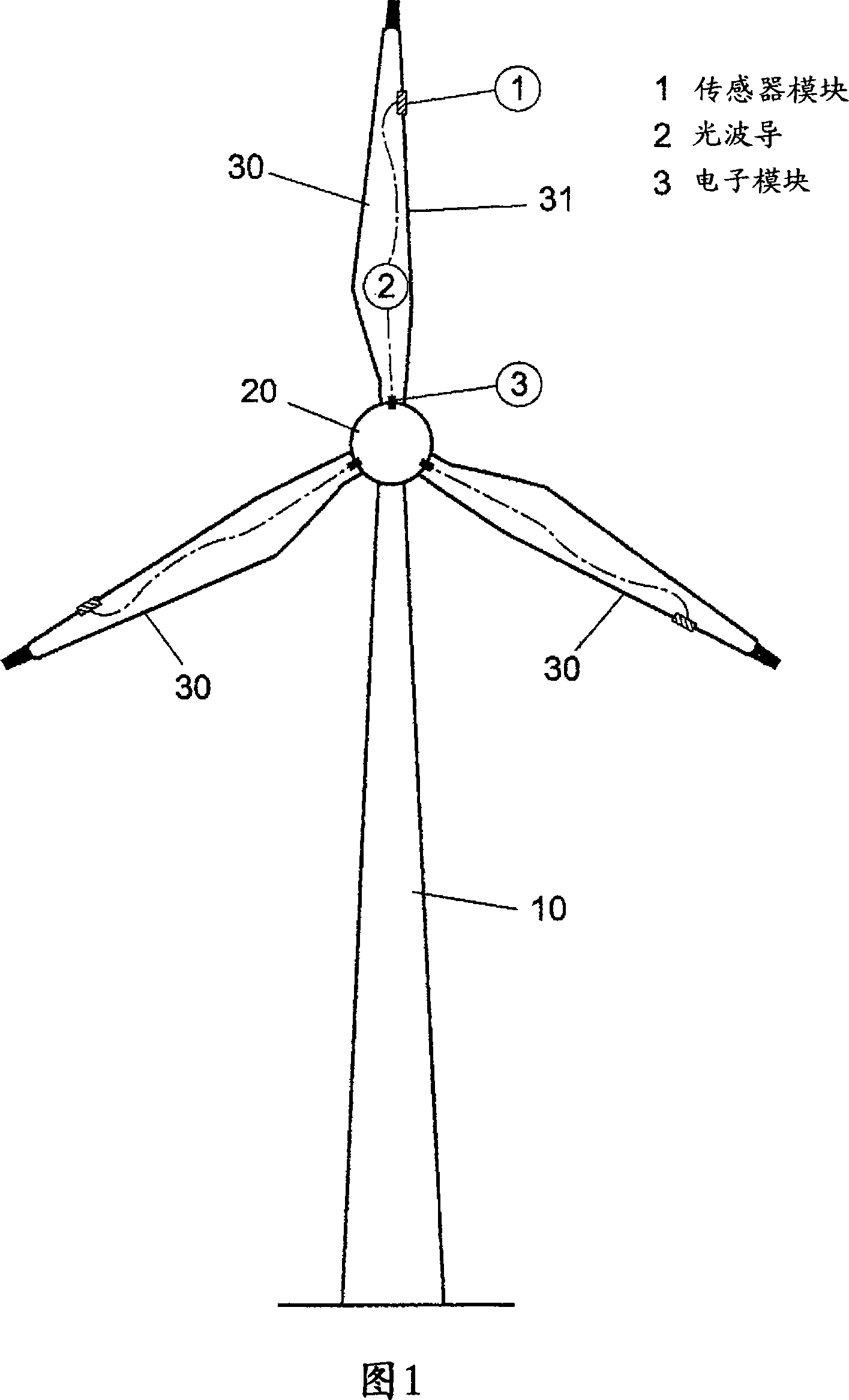

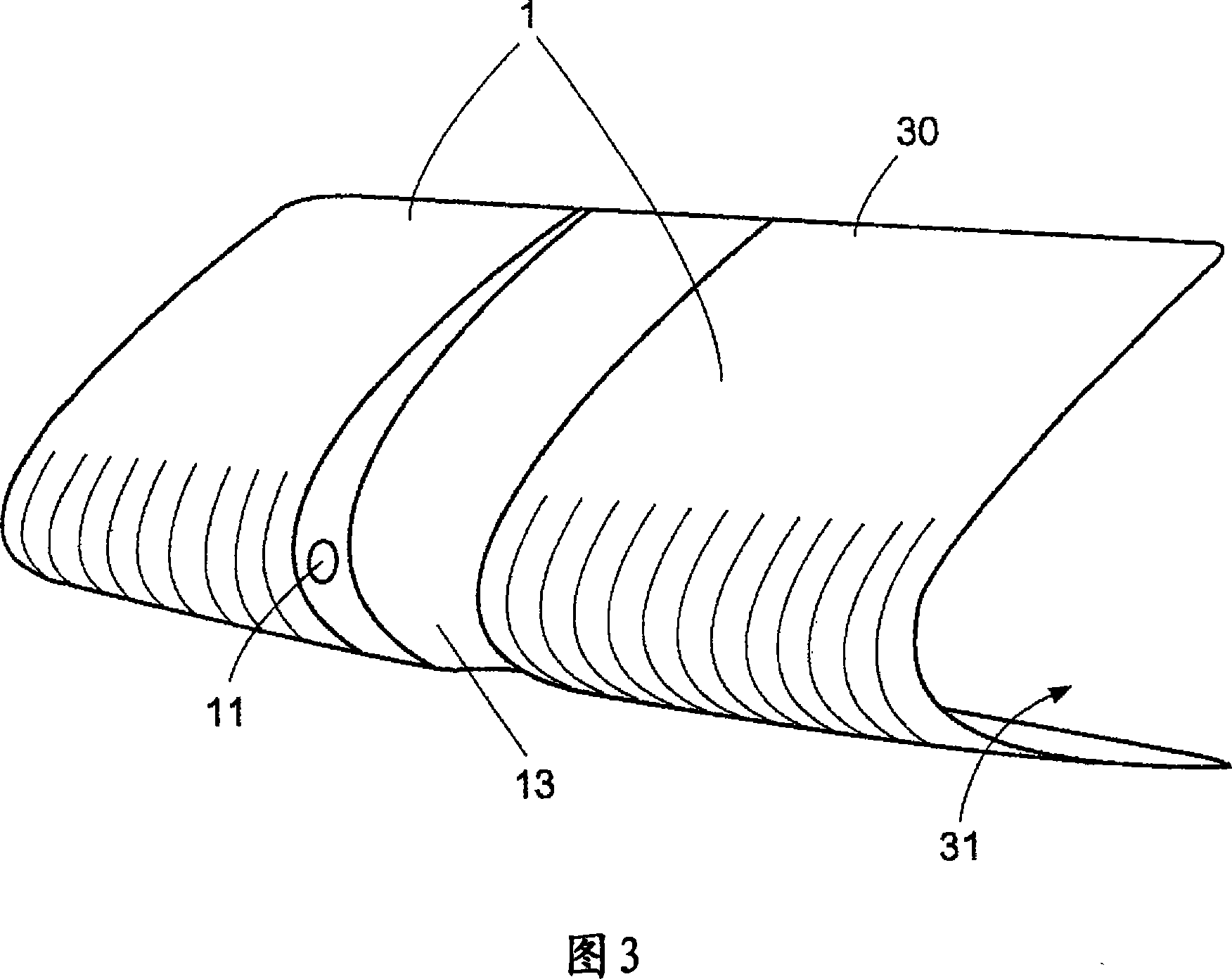

[0022] FIG. 1 shows a front view of a wind power plant according to a first embodiment. In this case, the wind power plant has a tower 10 , a nacelle 20 and three rotor blades 30 . A deposit sensor 1 is arranged on each rotor blade. Preferably, the deposit sensor 1 is arranged on the rotor blade nose. The deposit sensors 1 are respectively connected to a comparison device 3 via an optical waveguide 2 .

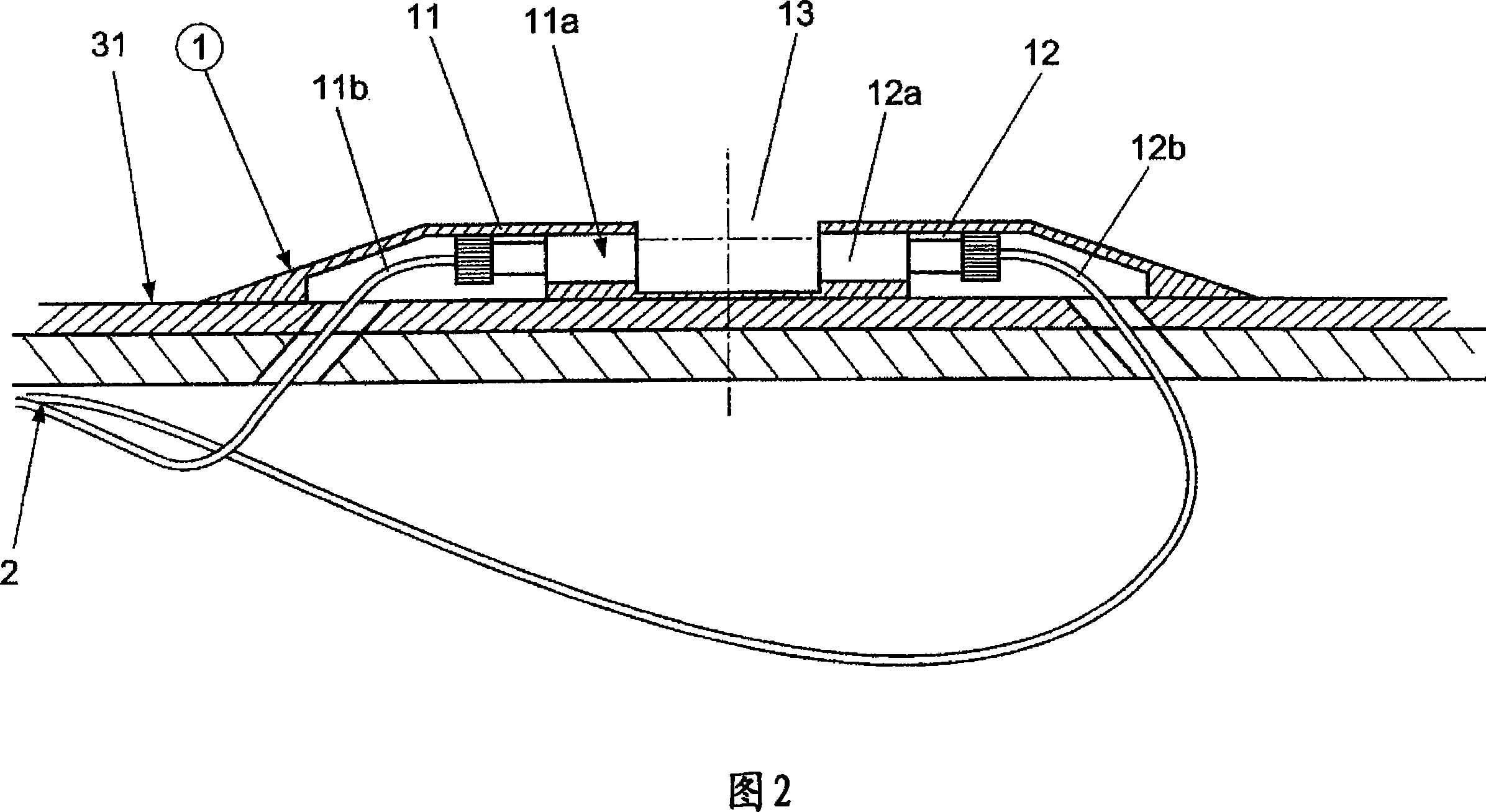

[0023] FIG. 2 shows a sectional view of a section of a rotor blade 30 of the wind power plant of FIG. 1 . Here, in particular, a section of the rotor blade in the region of the deposit sensor 1 is shown. The deposit sensor is installed in the region of the rotor blade nose 31 of the rotor blade 30 . The deposit sensor 1 basically consists of an optical transmitter 11 and an optical receiver 12 . The optical transmitter 11 is provided with a coupling-out lens 11a and the optical receiver 12 is provided with a coupling-in lens 12a. The optical transmitter 11 and the optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com