Injection-molded connectors with layer structure for electric vehicles

A cable and electric energy technology, which is applied in the field of injection-molded encapsulated connectors with a layered structure for electric vehicles, can solve the problems such as the inability to detect the heating of the electrical conductor with a delay, the temperature sensor is not installed close enough, etc. The effect of large effective range, increased amplitude, and fast response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

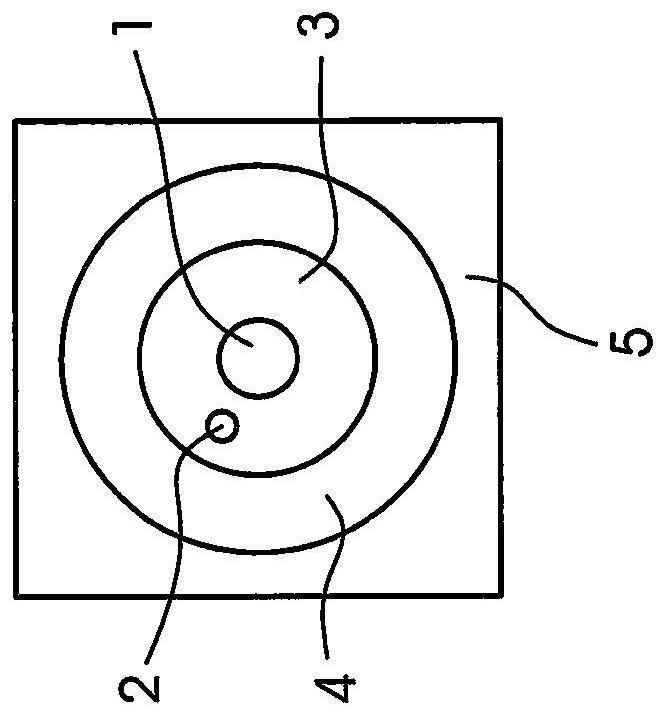

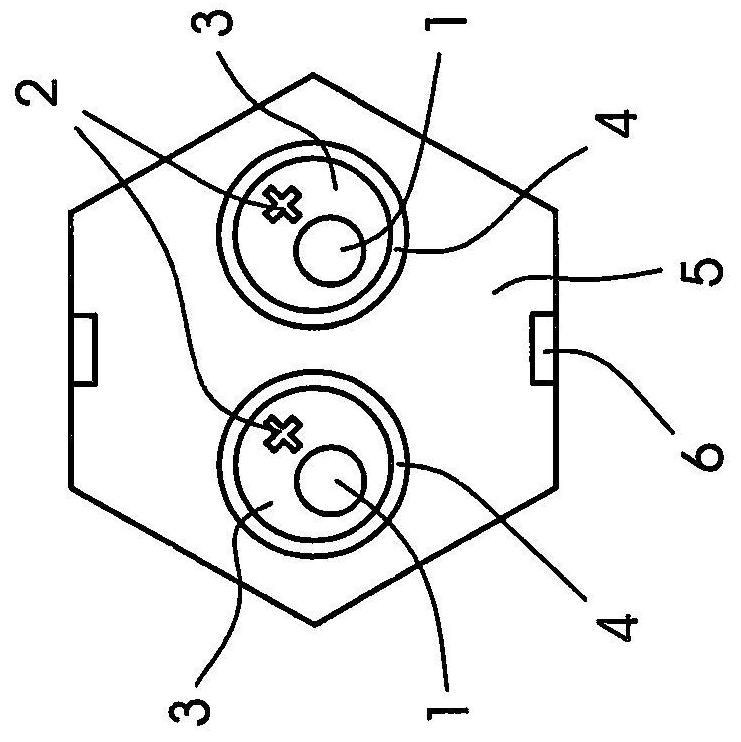

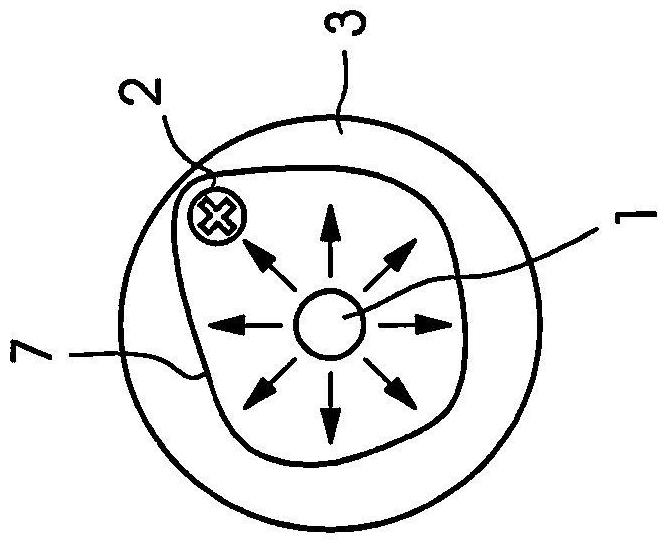

[0025] exist figure 1 An electrical conductor 1 (for example a cable or a plug connector) is shown by way of example in FIG. 2 , wherein the electrical conductor 1 is surrounded by a first layer 3 which is designed to be electrically insulating and thermally conductive at the same time. Around the first layer 3 there is provided an electrically insulating and at the same time thermally insulating second layer 4 which is in turn surrounded by an outer third layer 5 which insulates the cable from the external environment. The third outer layer 5 must be neither electrically nor thermally insulating, and it can only be equipped with the outer shape of the cable or the connector depending on the design. Inside the electrically insulating and thermally conductive first layer 3 there is a temperature sensor 2 which detects the temperature of the electrical conductor 1 . This happens in that when the electrical conductor 1 heats up, the heat is transferred to the temperature sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com